Method for predicting comprehensive performances of motorized spindle

A technology of comprehensive performance and prediction method, applied in the direction of instrument, adaptive control, control/regulation system, etc., can solve the problem of inability to comprehensively and accurately evaluate the real performance and operating conditions of the electric spindle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0070] The present invention will be further described below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

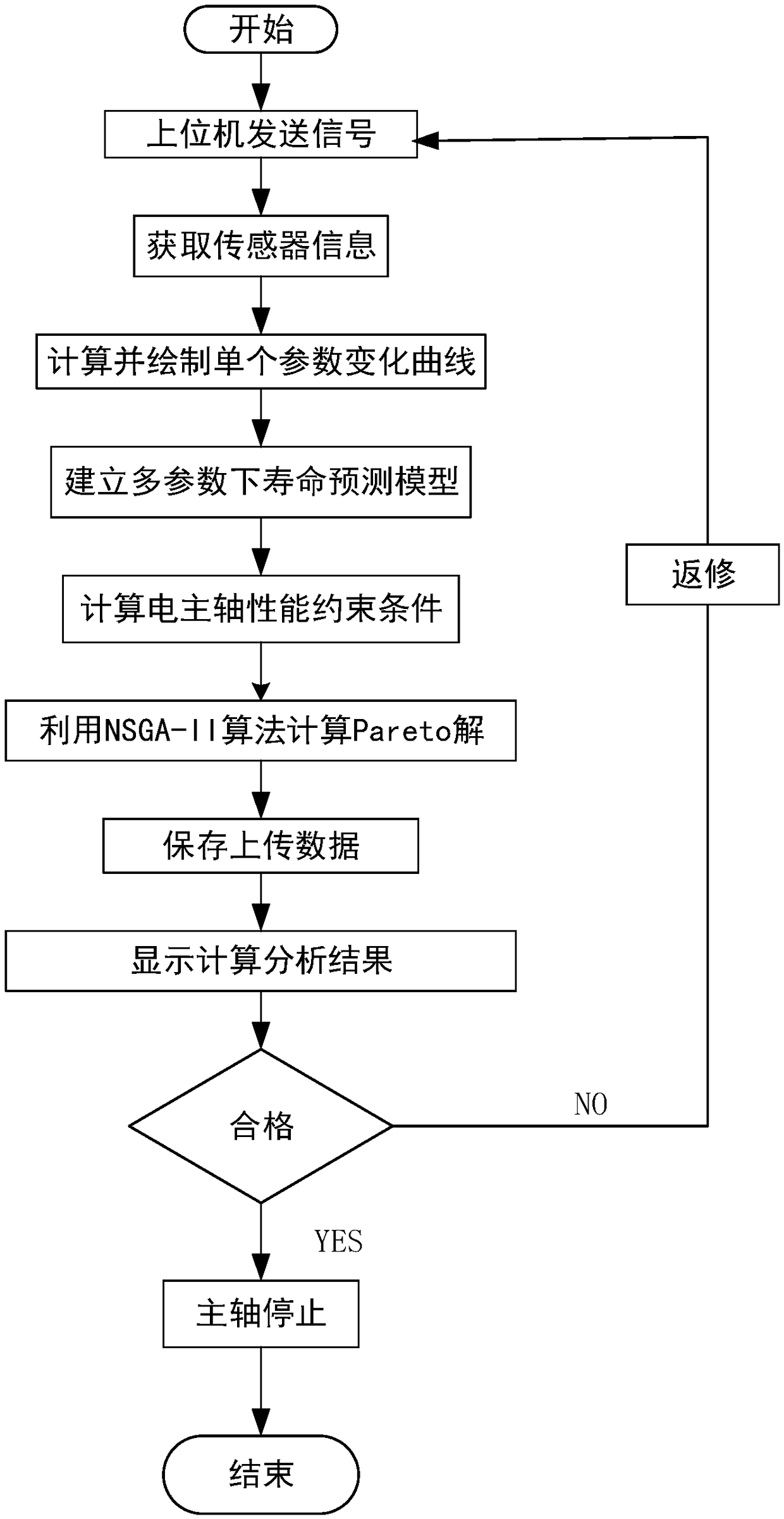

[0071] like figure 1 As shown, a method for predicting the comprehensive performance of the electric spindle, including the measurement of the dynamic rotation accuracy and vibration of the electric spindle in the dynamic and static state, such as temperature rise, noise, vibration, runout, etc., and the measurement of the dynamic rotation accuracy and vibration of the electric spindle test for accurate test results. The present invention specifically comprises the steps:

[0072] The technical points of the noise test method in the electric spindle comprehensive performance test system are:

[0073] First, the system confirms that the cooling and lubricating device of the electric spindle an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com