Automatic delivery device of tablet raw material

A technology of automatic feeding and tableting, which is applied in feeding devices, chemical instruments and methods, chemical/physical processes, etc., can solve the problems of unsuitable chemical raw material tablet feeding, etc., and achieves a high degree of automation, liberation of manpower, and reliability. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

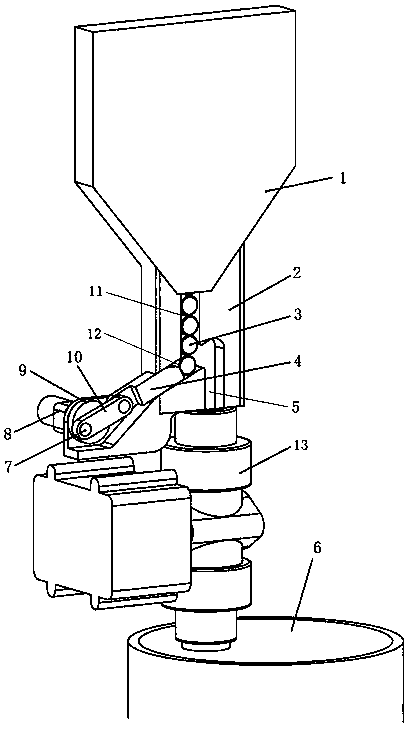

[0016] The dosing device of the present invention automatically adds solid tablet raw materials to the reactor. With automatic control, it is possible to realize regular dosing of tablets 3 one at a time. Tablet 3 can be sealed and stored during dosing and placement, which effectively liberates manpower and improves the automation of equipment.

[0017] like figure 1 As shown, the tablet raw material automatic feeding device of the present invention includes a material guide seat 2, a material pushing mechanism and an electric valve 13. The material guiding seat 2 is provided with a material guiding groove 11 , a material pushing groove 12 and a material dropping groove 5 . The upper opening of the guide groove 11 is provided with a tablet box 1, the tablet box 1 is flat, the lower part is funnel-shaped, Y-shaped, and the thickness of its inner cavity is consistent with the thickness of a single tablet 3, the bottom of the tablet box 1 The outlet is consistent with the diam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com