Portable steel bar bending equipment

A portable, steel bar technology, applied in the field of hardware processing, can solve the problems of inconvenient use, steel bar bending processing, large bending equipment, etc., and achieve the effects of easy portability, small equipment occupation space, and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

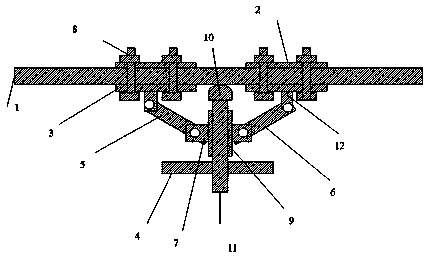

[0014] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

[0015] see figure 1 , the technical solution of the present invention is:

[0016] A portable steel bar bending equipment, the portable steel bar bending equipment includes: a steel bar clamping mechanism, a bending and ejecting mechanism and a connecting force arm, the steel bar clamping mechanism includes a first splint 2 and a second splint The splint 3 is connected with fastening bolts 8 between the splints, and the second splint 3 is connected with the connecting force arm through a movable connection pin 12. A bending ejection mechanism is arranged in the middle of the force arm, and the bending The ejector mechanism includes a threaded ej...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com