Light, portable and environment-friendly differential shell long-distance transportation set

A technology of long-distance transportation and poor casing, applied in the field of automobile manufacturing, can solve the problems of easy bump damage, rust, and space occupation of parts, and achieve the effect of avoiding bump damage, reducing costs, and reducing a large amount of space occupied.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

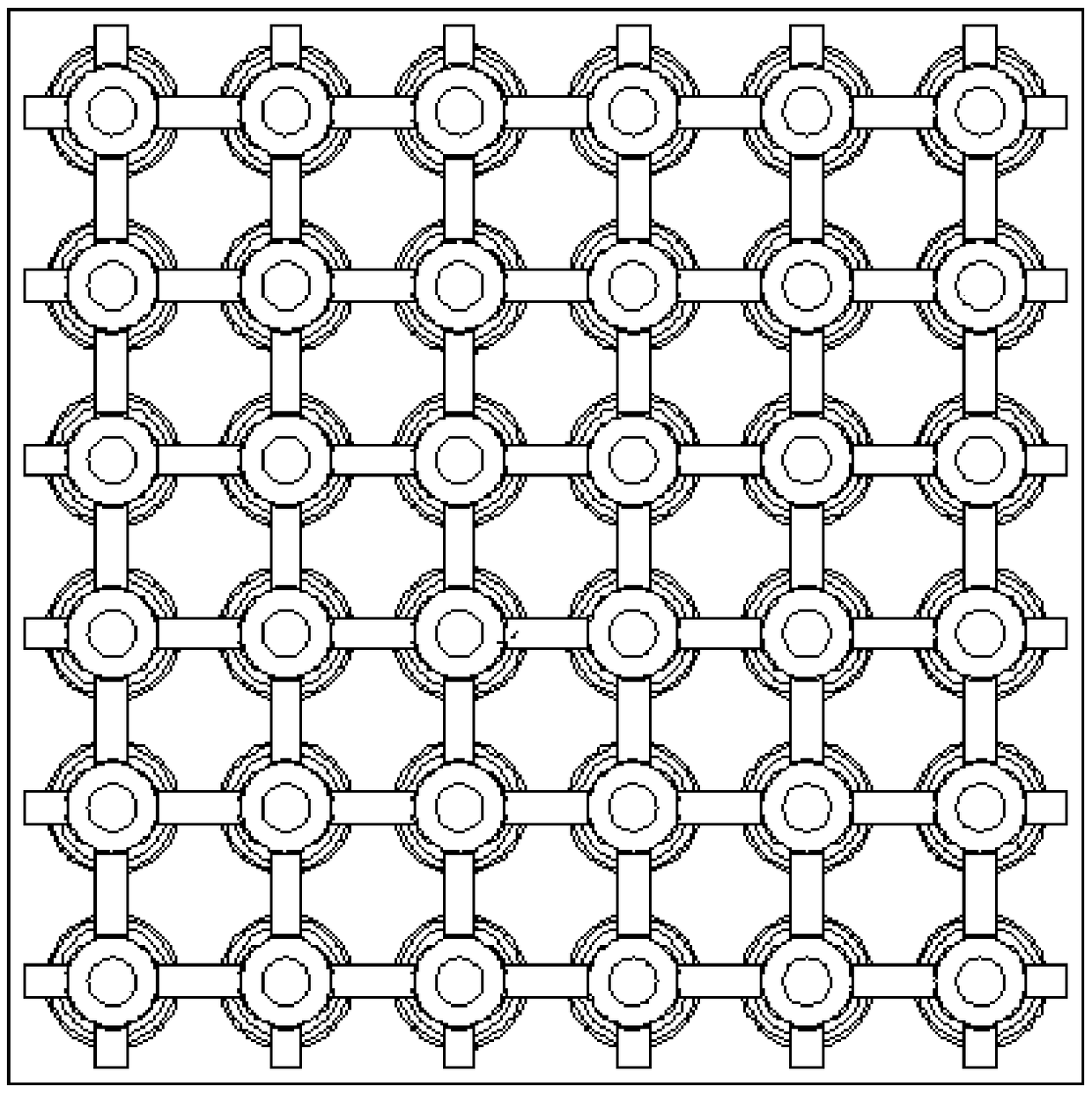

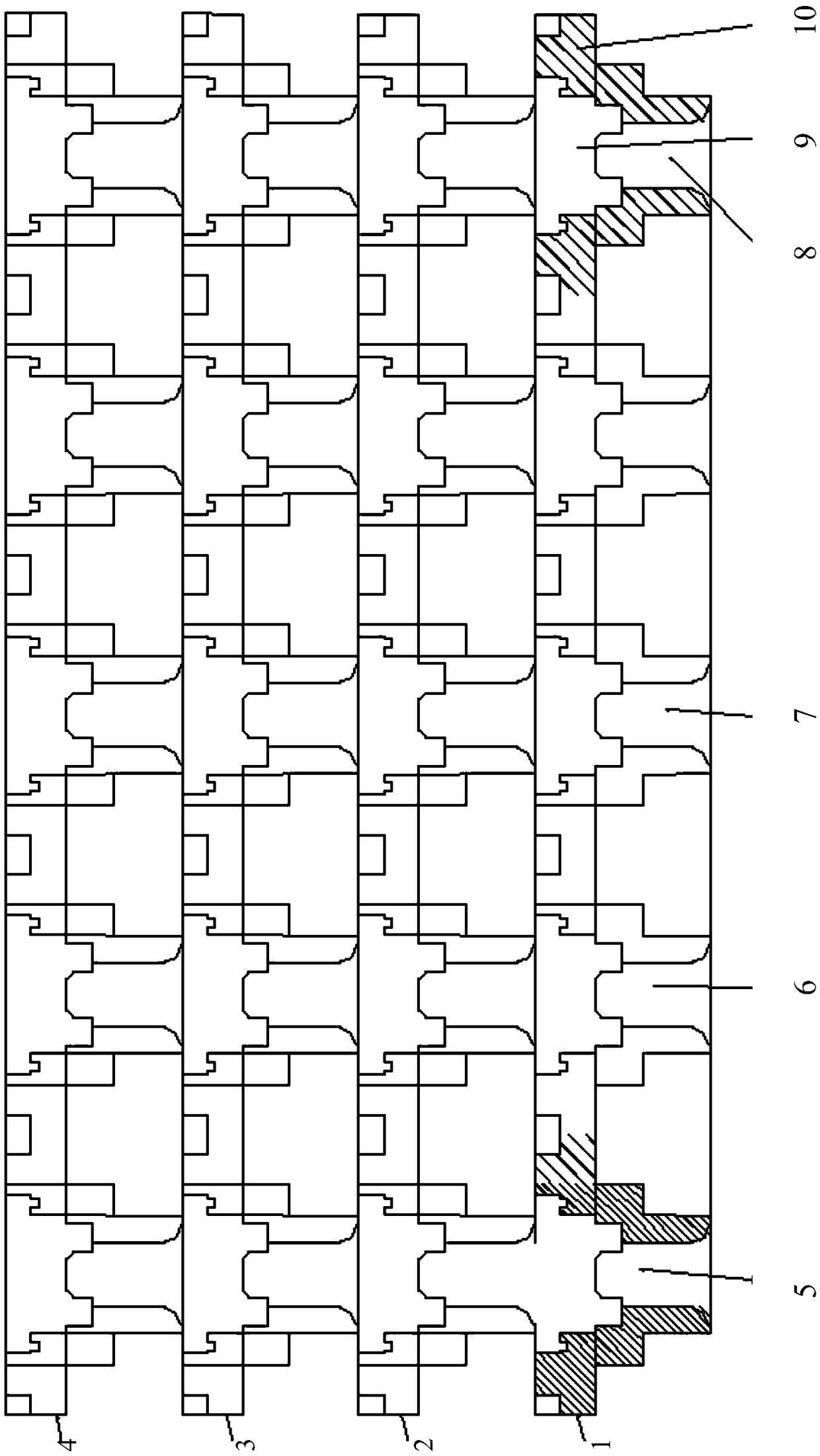

[0022] Such as Figure 1-Figure 3 As shown, a light and environment-friendly poor shell long-distance transport suit, including the first layer of transport box 1, the second layer of transport box 2, the third layer of transport box 3 and the fourth layer of transport box 4, A plurality of differential shells and a plurality of reinforcing ribs 10 .

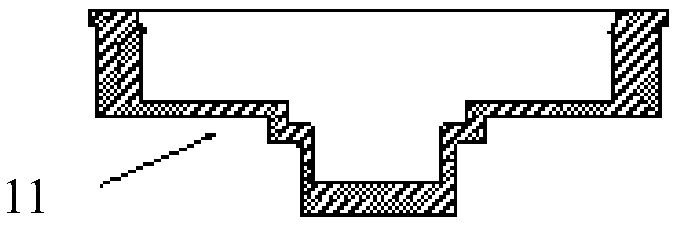

[0023] Such as Figure 3-5 As shown, the differential shell is composed of an integrally formed upper differential shell 12 and a lower differential shell 11, and the lower differential shell 11 is composed of and and The hollow cylinder and the 150*5*5 hollow cylinder are successively transitioned and connected. The upper differential shell 12 consists of The cylindrical empty box and the bottom end are the top is Cone empty box with a wall thickness of 5mm and Cylindri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com