Quick coupling structure

A joint structure and fast technology, applied in mechanical equipment, couplings, etc., can solve the problems of loss of rebound function, unreasonable design, rupture of rebound mechanism, etc., and achieve the effect of prolonging service life, reasonable design and avoiding fracture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

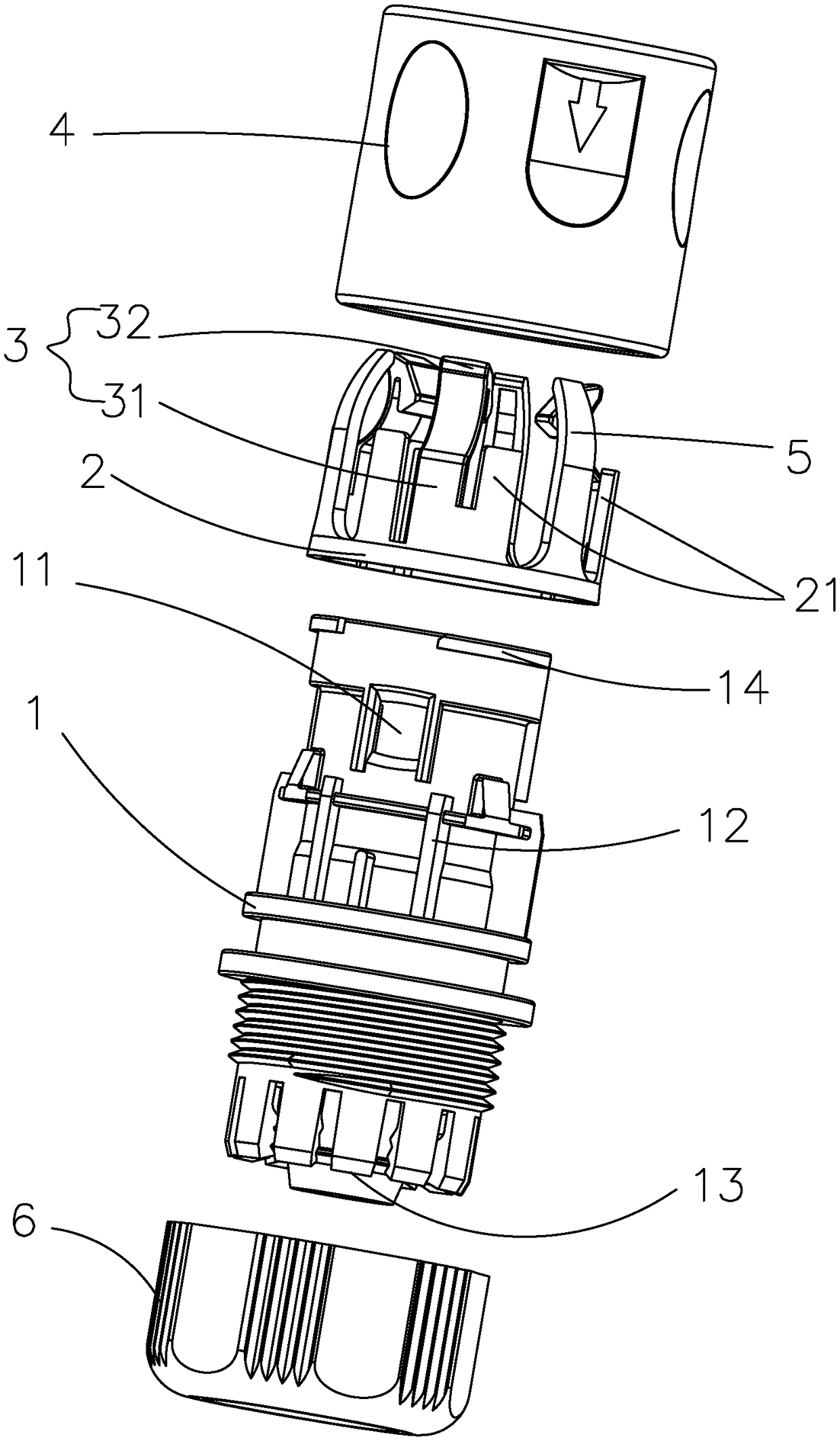

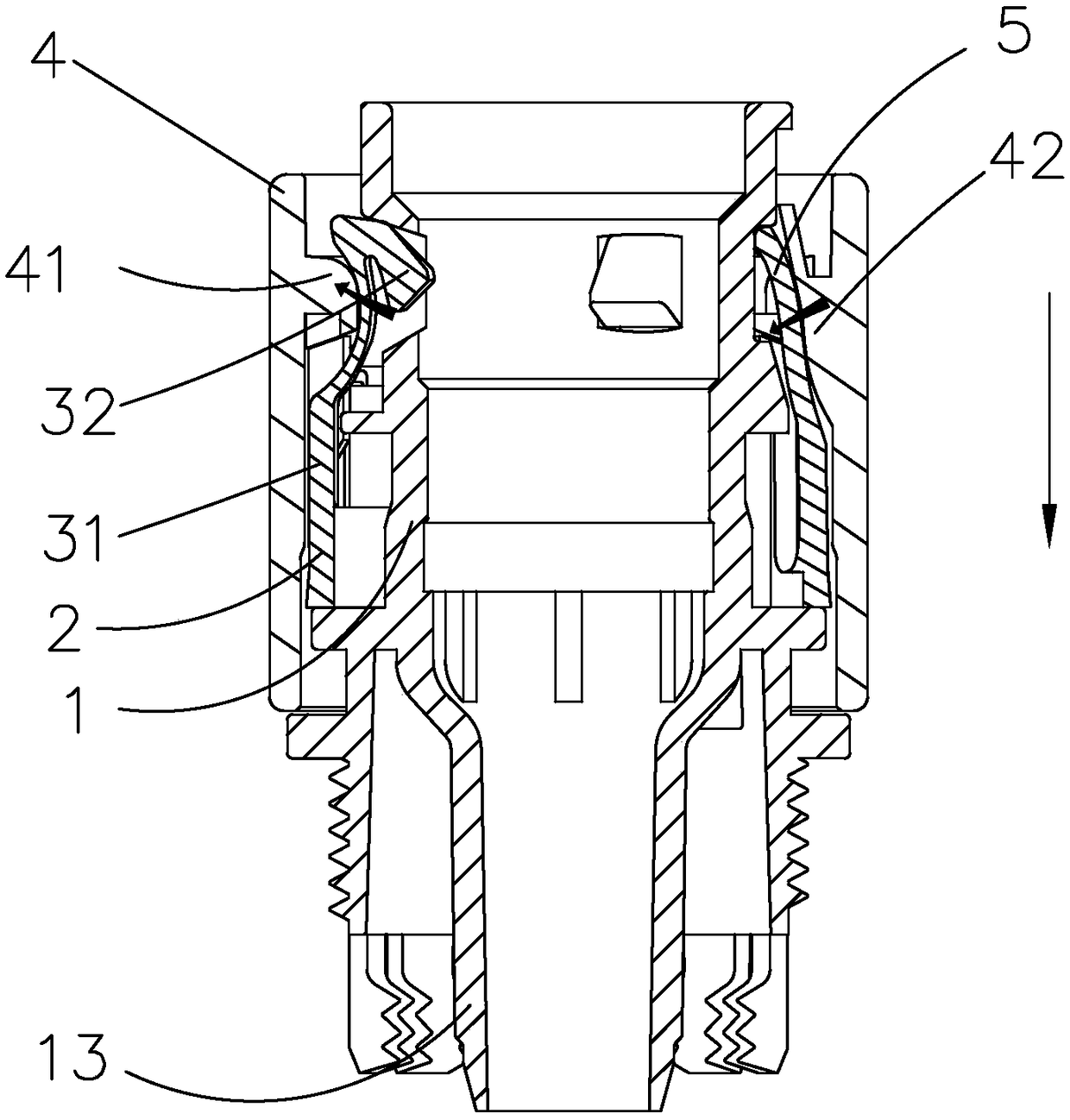

[0024] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

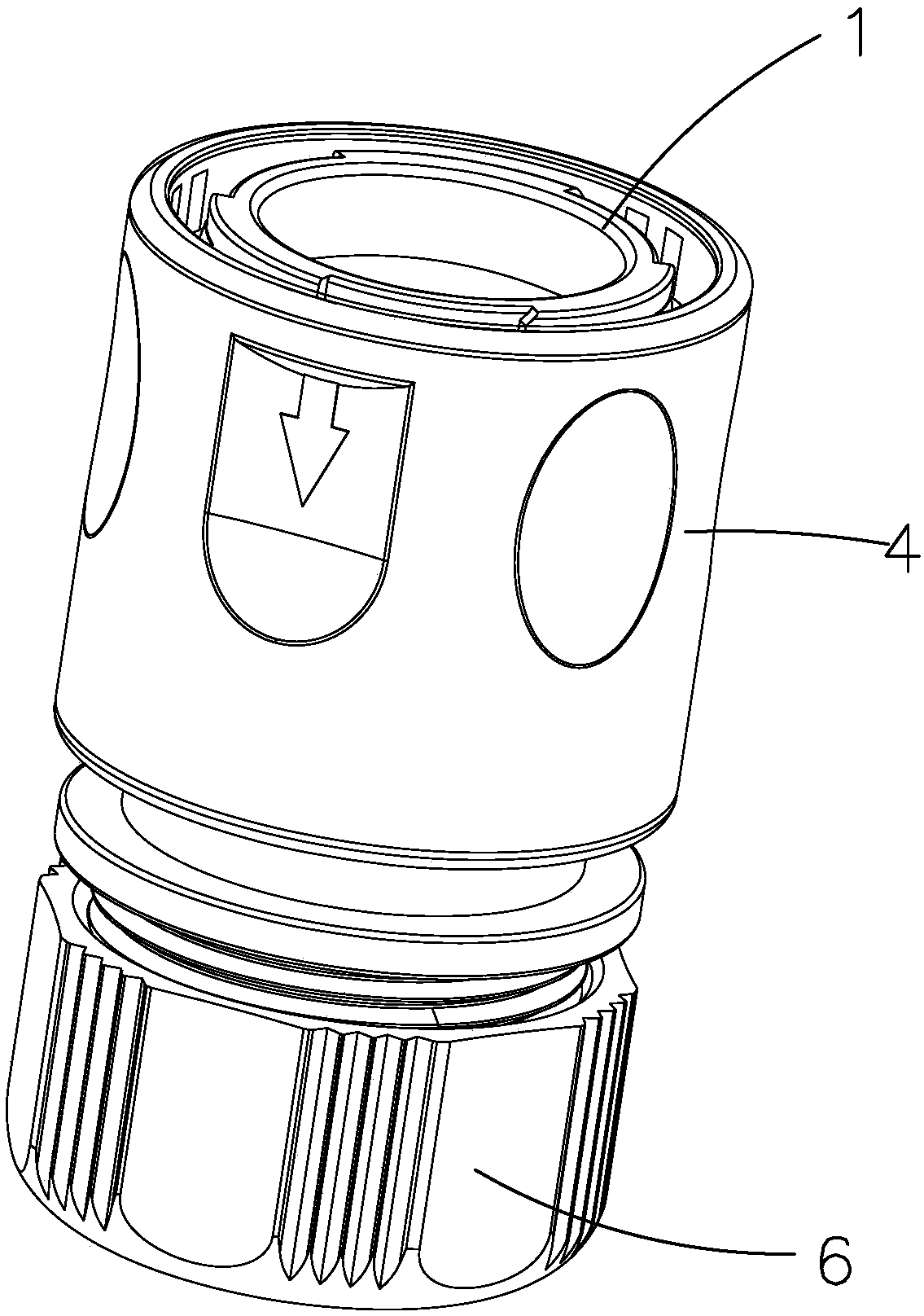

[0025] like Figure 1 to Figure 6 As shown, a quick joint structure includes a joint body 1 that can be inserted into the insertion tube. The joint body 1 is connected with a fixing seat 2, and the fixing seat 2 is provided with a device that can be used for Clamp the elastic clamping part 3 of the insertion tube. The fixed seat 2 is covered with a shell 4 that can slide relative to it. 3. The elastic clamping part 3 clamps the first protruding part 41 of the insertion tube. When the housing is in the initial position, the first protruding part of the inner wall of the housing presses against the elastic clamping part and then clamps the insertion tube to be in a clamped state. When the insertion tube cannot be pulled out, the fixed seat 2 is provided with a first shrapnel 5 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com