Chassis vehicle

A technology of chassis and frame, which is applied in the direction of switchgear, pull-out switch cabinet, electrical components, etc. It can solve the problems of heavy operation of the chassis, failure of interlocking mechanism interlocking, and easy deflection of the frame. Achieve the effect of improving sensitivity, small operating force, and sensitive locking and bouncing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

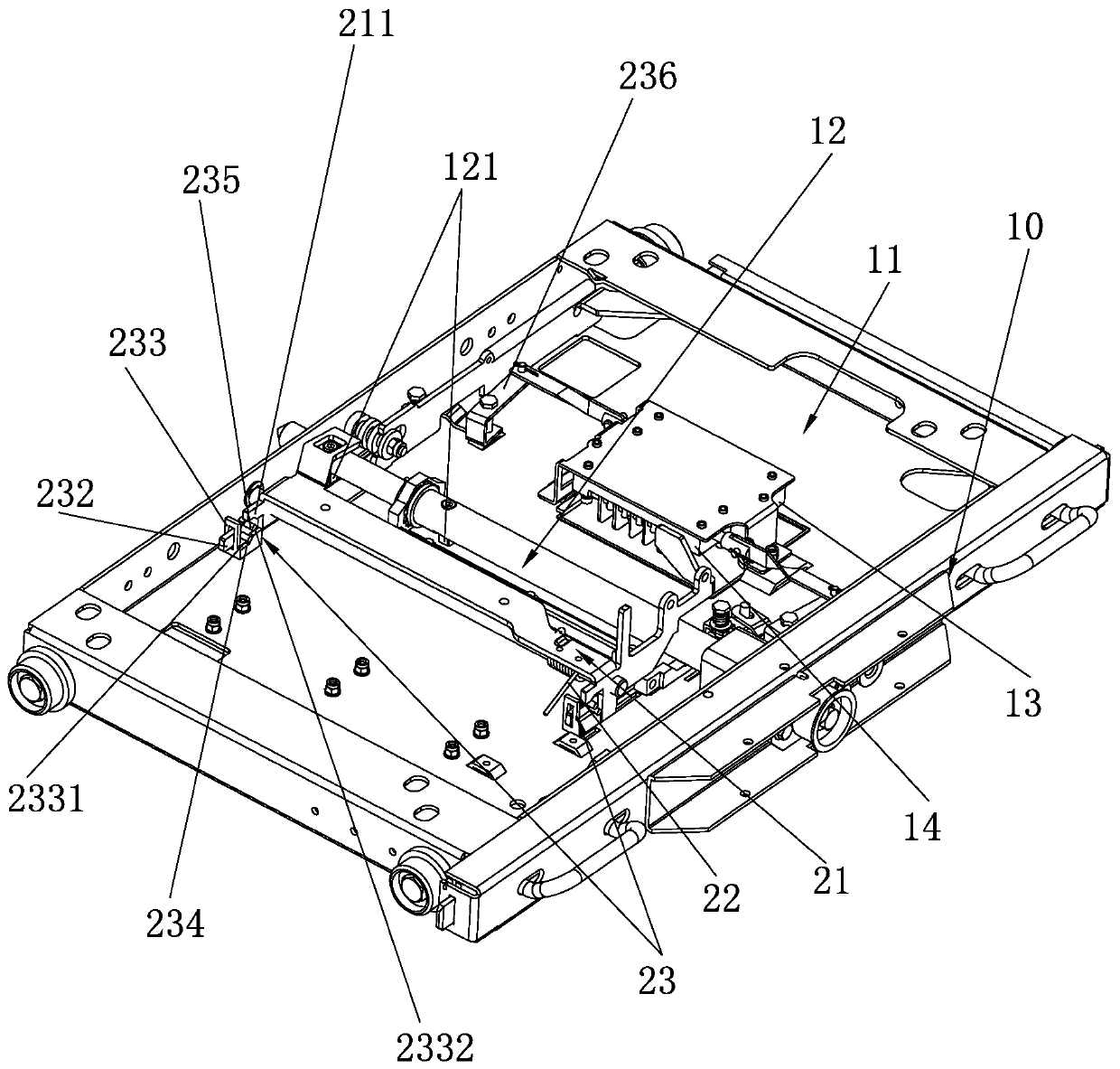

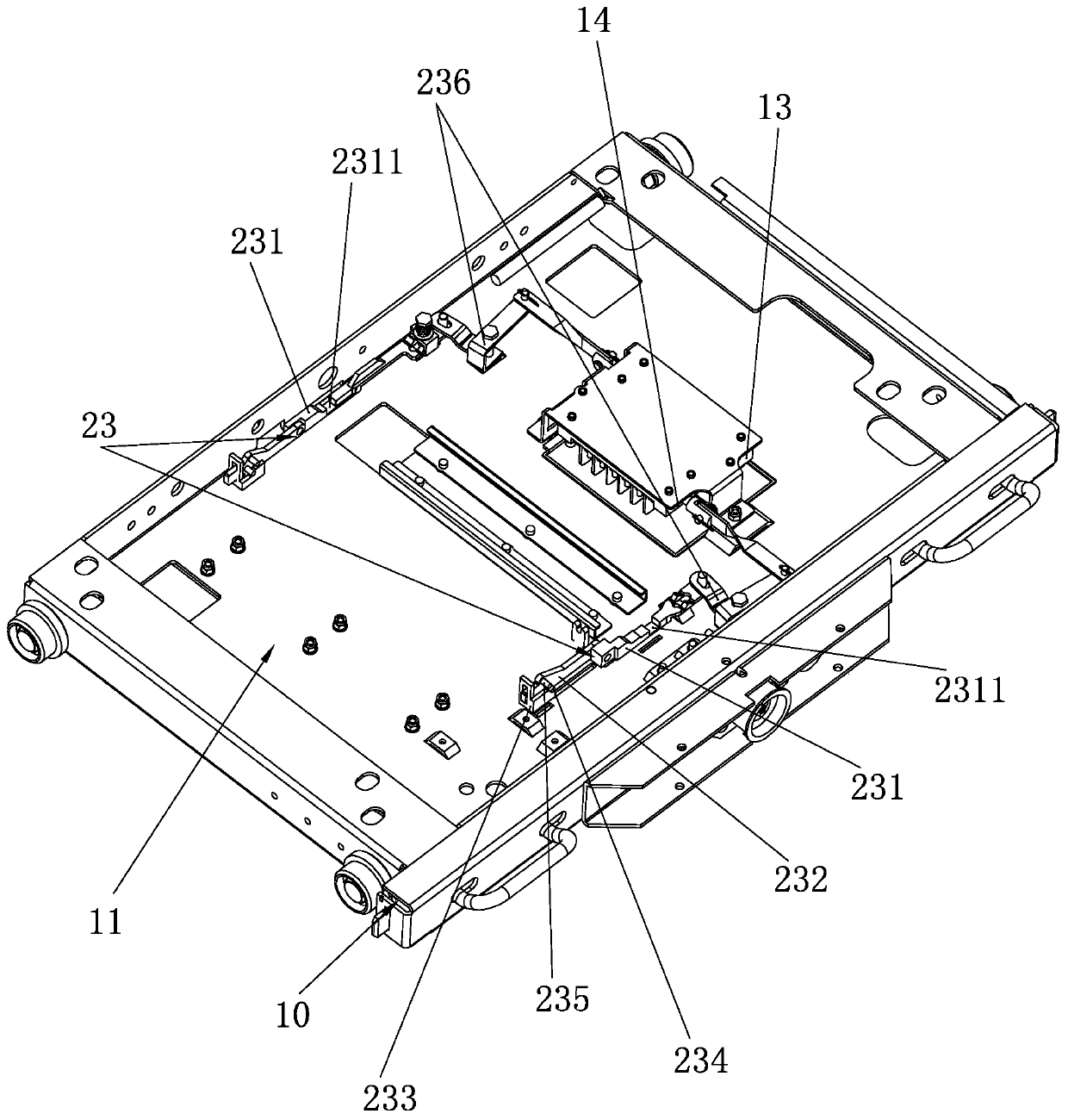

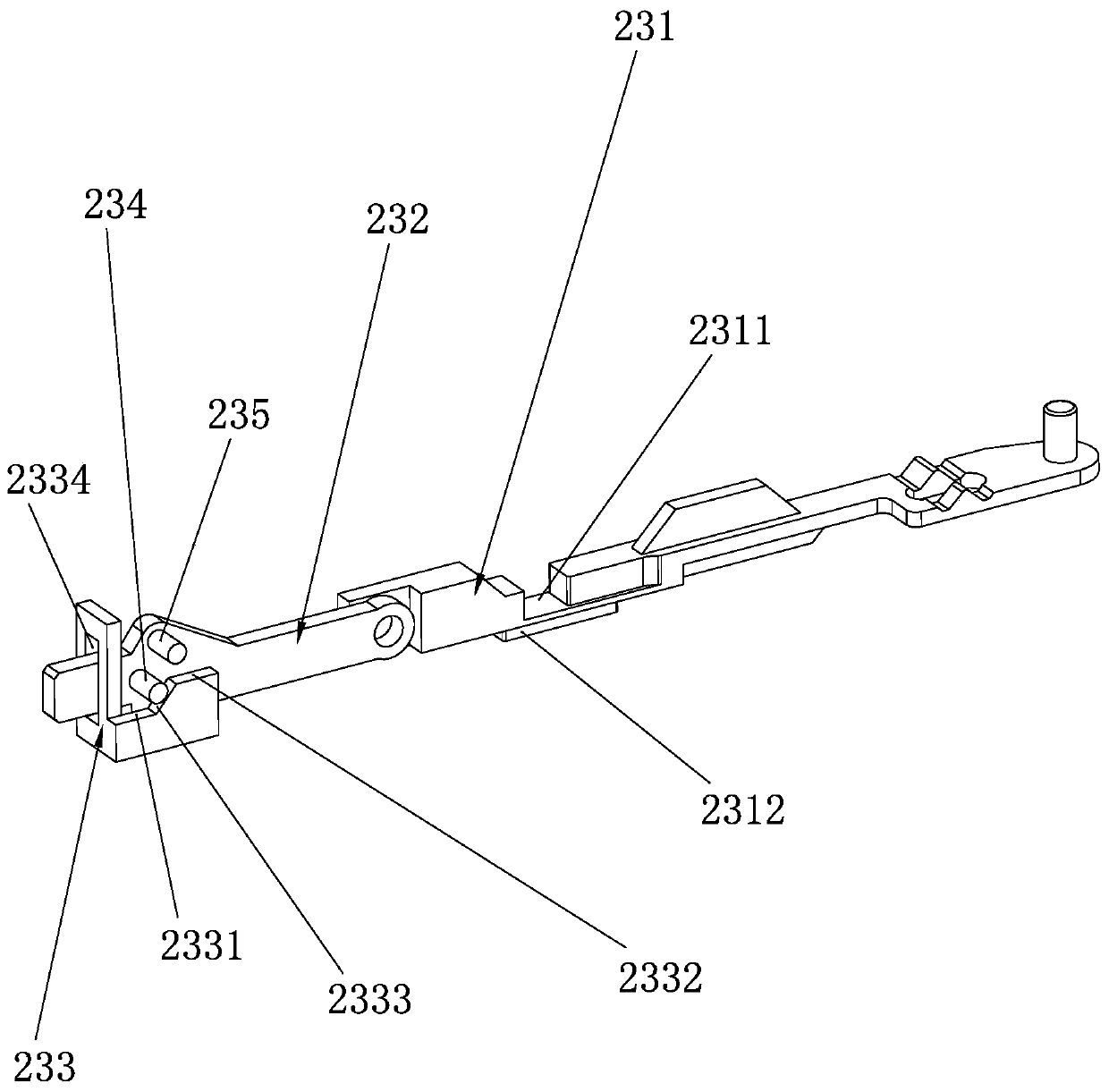

[0018] Such as Figure 1~5 As shown, the embodiment of the present invention is a chassis vehicle, including a crossbeam 10, a vehicle frame 11 arranged on the crossbeam 10, a screw rod 12, an interlock mechanism 20 arranged in the vehicle frame 11, and an interlock mechanism 20 arranged in the vehicle frame 11 respectively. The test position auxiliary switch 13 and the working position auxiliary switch 14, the interlock mechanism 20 includes a lock plate 21 which is rotatably arranged in the vehicle frame 11 and cooperates with the screw rod 12, and is arranged between the lock plate 21 and the vehicle frame 11. Between the reset torsion spring 22, two groups of interlocking components 23, the two groups of interlocking components 23 are respectively arranged between the locking plate 21 and the test position auxiliary switch 13, the working position auxiliary switch 14, the described interlocking components 23 includes a slider 231 slidably arranged in the vehicle frame 11 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com