Dispenser Ejection Dispensing Module

A glue dispensing machine and glue dispensing technology, applied in the field of glue dispensing machines, can solve the problems of difficulty in controlling glue output, increase production cost, slow glue dispensing machine speed, etc., reduce glue pressure, prolong service life, workmanship many effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

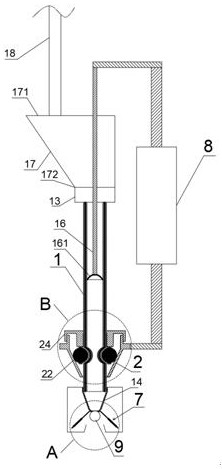

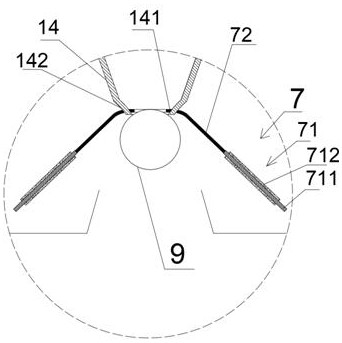

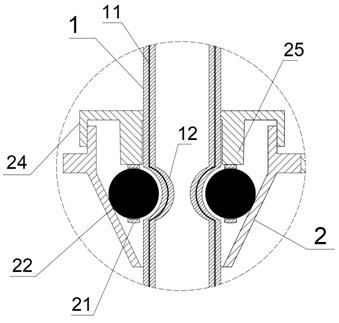

[0032] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0033] see Figure 1 to Figure 3 , the ejection type dispensing module of the dispensing machine, including the rubber outlet tube 1 and the rubber extrusion sleeve 2 slidingly set outside the rubber outlet tube 1; when the rubber outlet tube 1 moves toward the head of the rubber outlet tube 1 relative to the extrusion sleeve 2, The extruding sleeve 2 radially extrudes the rubber tube 1 so that the rubber is discharged from the head; along the outside of the head of the rubber tube 1, a number of piezoelectric springs 7 are evenly arranged; When the glue droplet 9 is extruded, the glue droplet 9 is ejected to the front by a synchronous action.

[0034] Further, the piezoelectric elastic piece 7 includes a piezoelectric deformation component 71 and an elongated elastic metal sheet 72; the piezoelectric deformation component 71 includes a long...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com