Adjusting method of autotransformer with adjustable telescopic damping of carbon brush body

A technology of autotransformer and adjustment method, which is applied in variable transformers, transformers, variable inductors, etc., can solve the problems of winding wear, ineffective utilization, and burnout of equipment, so as to reduce wear rate and increase effective wear area, the effect of precise adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

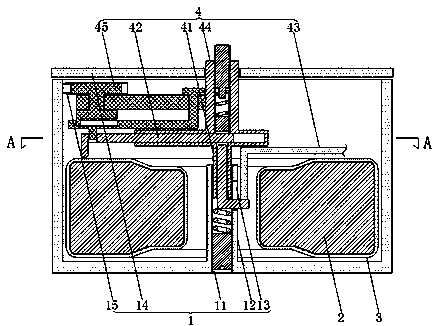

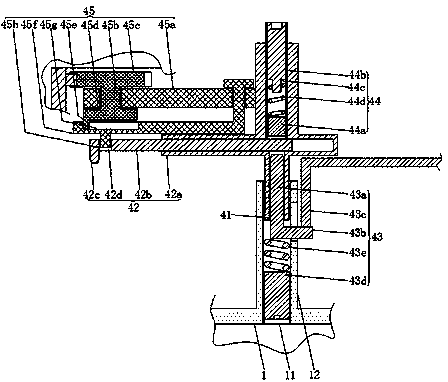

[0061] The present invention will be described in further detail below in conjunction with the accompanying drawings.

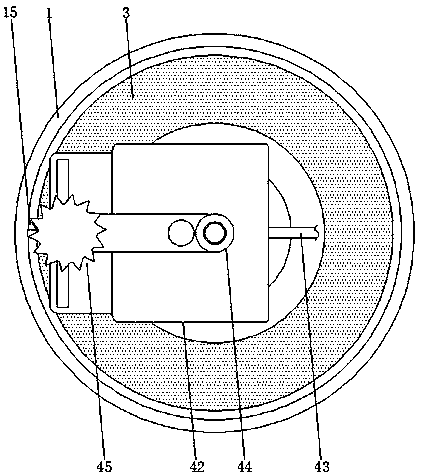

[0062] A carbon brush body telescopic damping adjustable autotransformer, comprising a casing 1, an annular iron core 2 arranged at the bottom of the casing 1, a winding 3 wound on the annular iron core 2, and a carbon brush arm 4;

[0063] The shell 1 is a hollow cylindrical shell, the center of the lower end surface of the shell 1 is provided with a lower through hole 11, the upper edge of the lower through hole 11 is provided with an internally threaded cylinder 12, and the side wall of the internally threaded cylinder 12 is arranged longitudinally. There is an outer wiring hole 13, the upper end of the shell 1 is open and detachably connected with an annular upper cover 14, and the inner end surface of the side wall of the shell 1 is provided with a pawl 15;

[0064] The carbon brush arm 4 includes:

[0065] The hollow tube 41 is slidably inserted in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com