Arc extinguishing fuse with open-circuit mark

A fuse and arc extinguishing technology, which is applied to circuits, electrical components, emergency protection devices, etc., can solve the problems of slow fuse fusing speed, harm, and increase the time of breaking the circuit, so as to achieve reliable operation, convenient use and simple structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

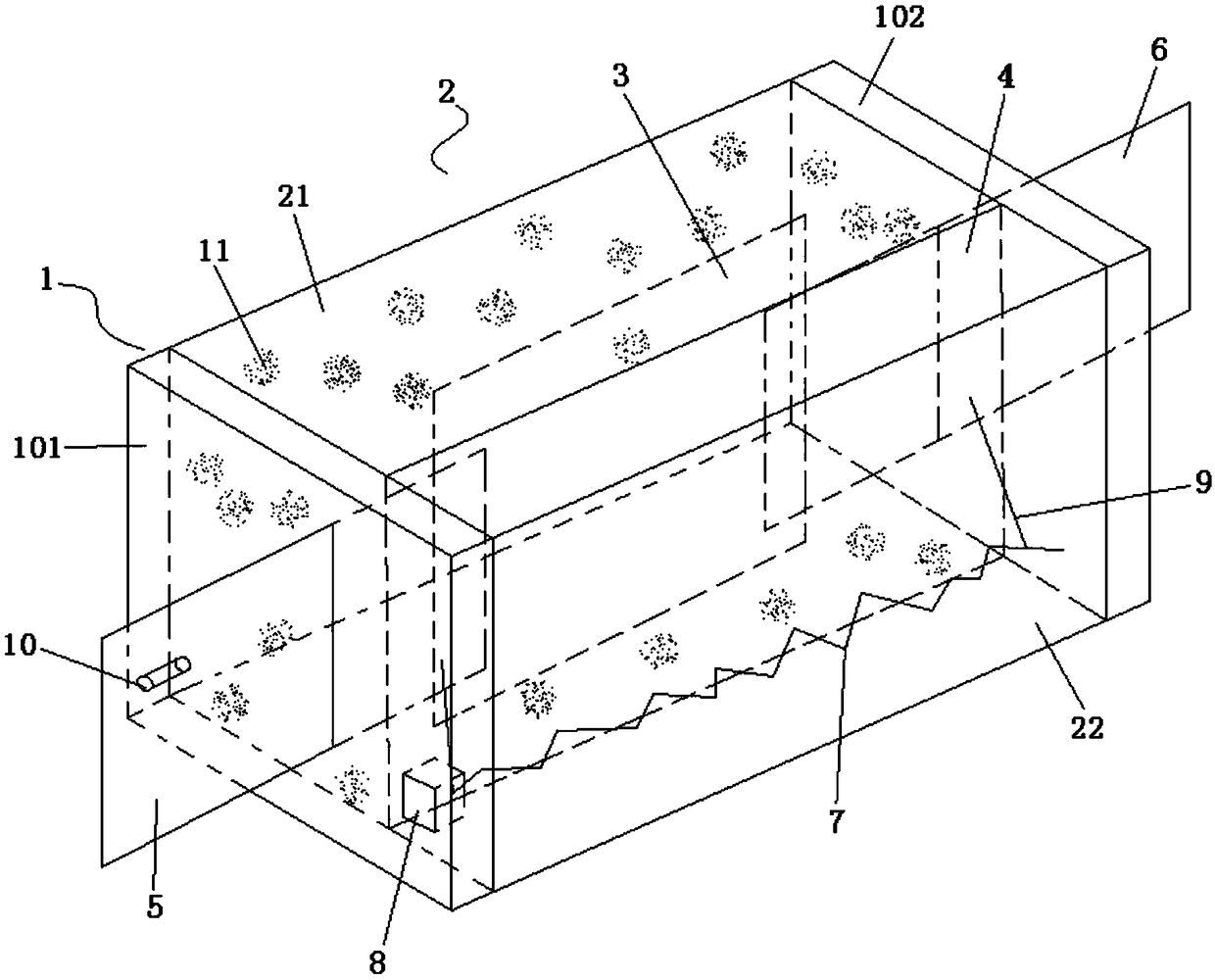

Embodiment 1

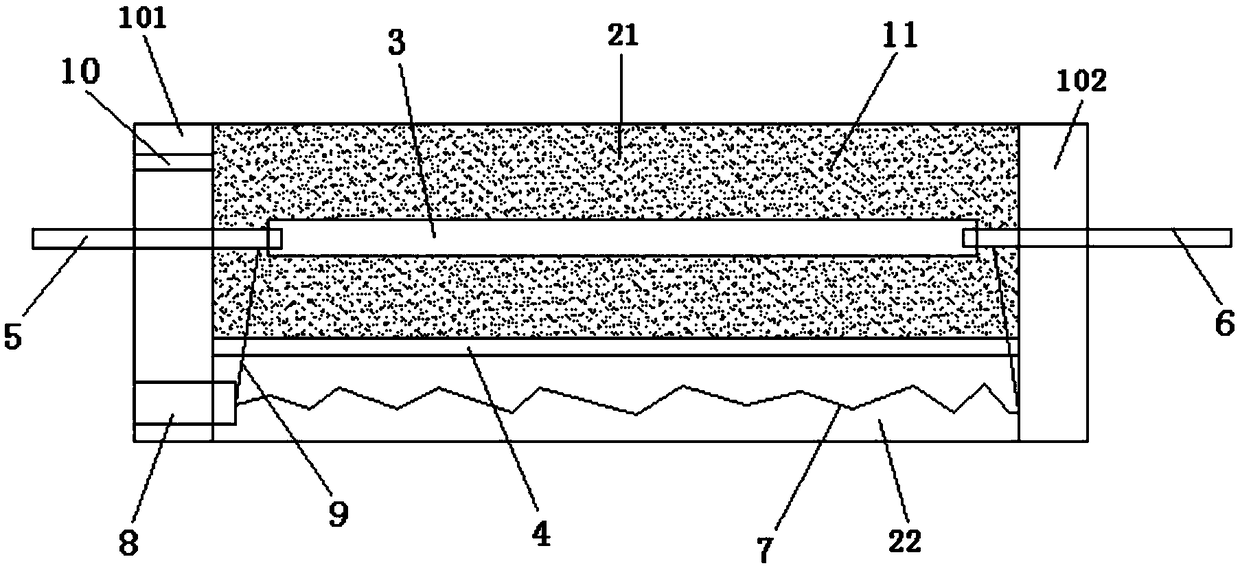

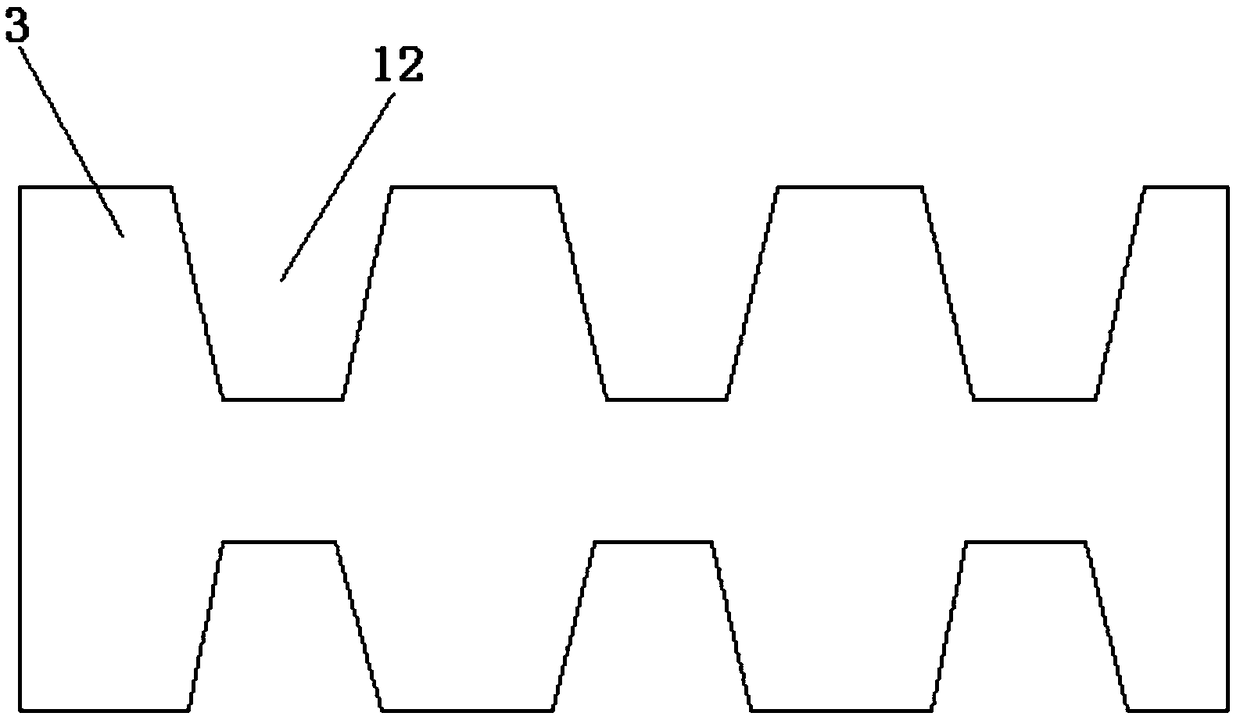

[0024] When in use, inject quartz sand into the first cavity through the sand injection hole, and the quartz sand plays the role of arc extinguishing after the melt is melted. Since the melt is provided with a cut corner, the wide body of the melt connection is changed, and the fusing time is shortened without changing the material of the melt.

[0025] A compressed return spring is arranged in the second cavity, and the two ends of the return spring are respectively connected to the first conductive sheet and the second conductive sheet through the thin constantan wire, and the thin constantan wire at the front end is also connected to the identification block , used to pull the identity block. The resistance value of the fine constant copper wire plus the return spring is slightly greater than the resistance value of the melt. When the melt is blown by a large current, the current only passes through the circuit of the fine constant copper wire and the return spring. At this...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com