Gas welding sealing process of 60 MPa ultrahigh-pressure cylinder

A process method and ultra-high pressure technology, applied in welding equipment, manufacturing tools, metal processing equipment, etc., can solve the technical problems of inflation, plugging, welding and sealing, and can not meet ultra-high pressure gas cylinders, etc. Operation, small tightening torque, simple operation and excellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

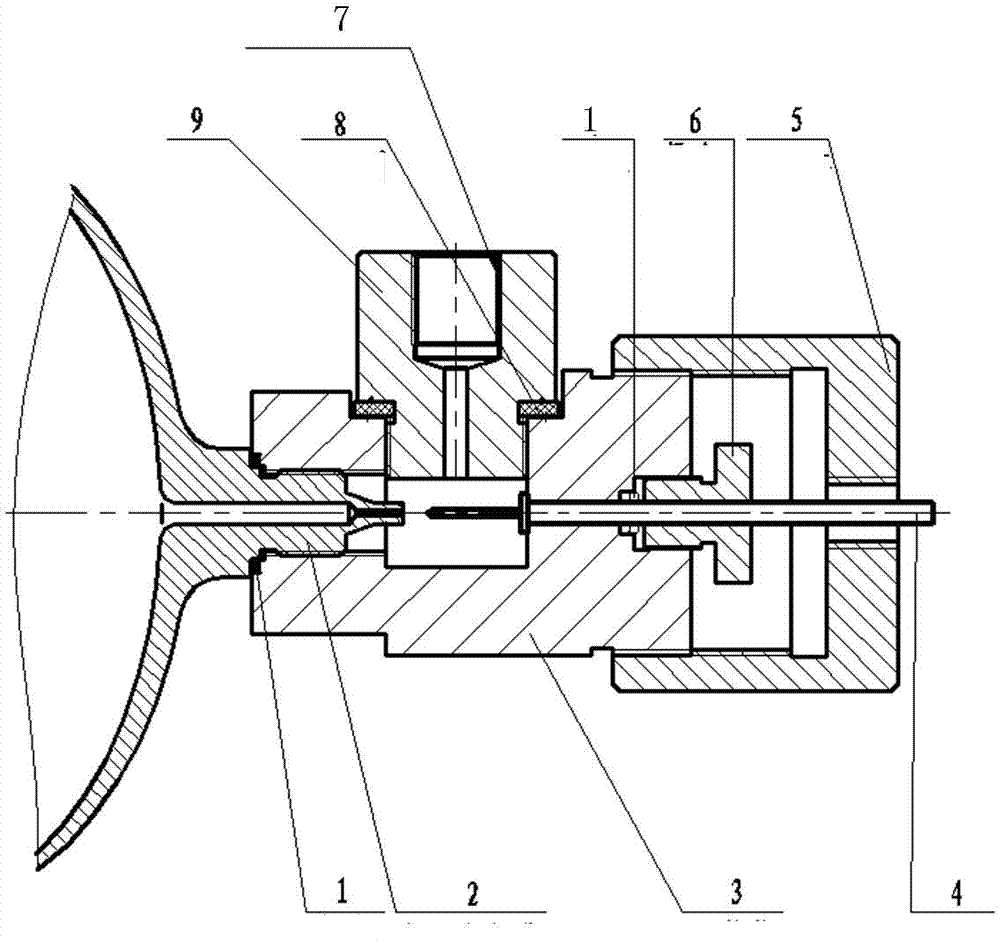

Image

Examples

Embodiment

[0016] Ultra-high pressure gas cylinders can be composite material high pressure gas cylinders or steel gas cylinders. Composite material high-pressure gas cylinders should include a steel liner and a winding layer. The steel liner is a stainless steel welded liner, which is machined, spun and stretched into two and a half liners of the cylinder body, and passed through an argon arc. An integral stainless steel inner tank obtained by welding a circumferential weld, or a steel inner tank directly formed by spinning and closing; an insulating layer is provided between the surface of the stainless steel inner tank and the carbon fiber winding layer; the outer protective layer of the gas cylinder It is a winding layer reinforced with high-strength glass fiber. The steel gas cylinder is a gas cylinder whose whole body is made of steel and formed by welding or spinning.

[0017] Concrete processing steps of the present invention are as follows:

[0018] Step 1, inflation process: ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com