Camshaft adjuster facilities and camshaft adjusters

A technology of camshaft adjuster and camshaft, which is applied in the direction of mechanical equipment, machine/engine, engine components, etc. It can solve the problems of tightening the central screw and difficult operation of the screw head, and achieve the effect of uniform distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

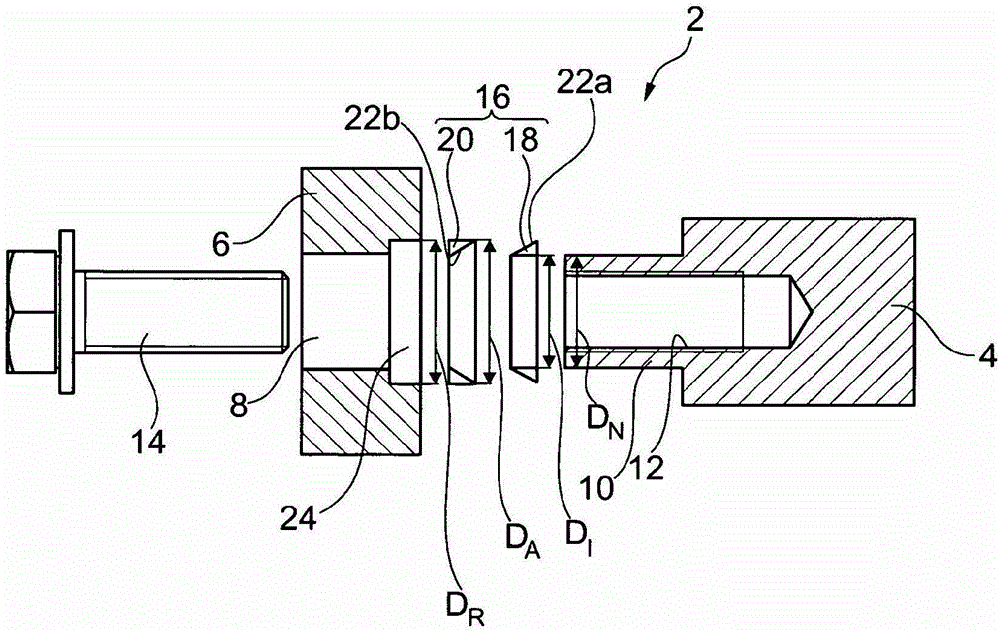

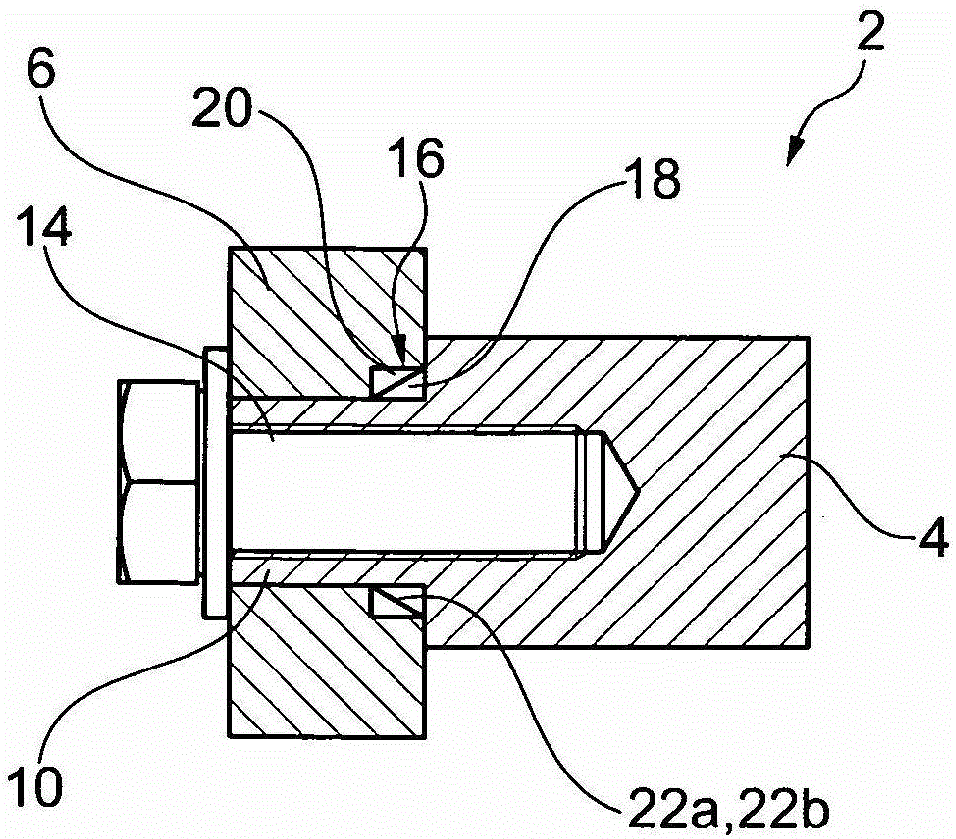

[0020] according to figure 1 and figure 2 The camshaft adjuster arrangement 2 comprises a camshaft 4 and a rotor 6 for a camshaft adjuster not shown in detail here, which is mounted on the camshaft 4 in a rotationally fixed manner. The camshaft adjuster is supplemented by a stator, not shown here, which is arranged concentrically in the rotor 6 .

[0021] The rotor 6 has a central bore 8 . An axially protruding cylindrical shoulder 10 is formed on the camshaft 4 , which is inserted into the central bore 8 in the assembled state. The shoulder 10 is substantially hollow and has an internal thread 12 . The fastening of the rotor 6 on the camshaft 4 takes place via a fastening element, in this case a central screw 14 screwed into the hollow shaft shoulder 10 .

[0022] The tightening torque of the central screw 14 is reduced in such a way that the non-positive connection is converted into a non-positive and frictional connection by using the tensioning sleeve 16 . In this ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com