Torque adjustable friction safety clutch

A safety clutch and torque adjustment technology, applied in clutches, automatic clutches, mechanical equipment, etc., can solve the problems of eccentric friction plate wear and low precision, and achieve the effect of not easy friction plate eccentric wear, convenient online adjustment, and obvious effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

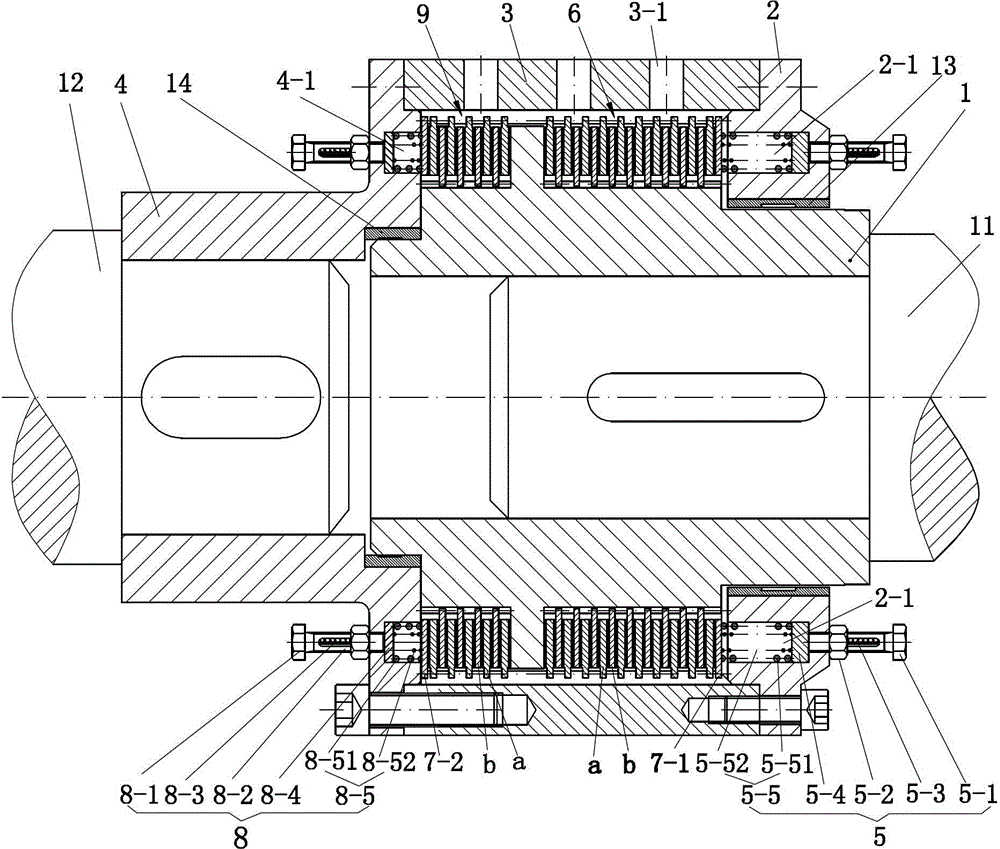

[0019] See figure 1 and figure 2 , this embodiment includes a housing 3, on which a number of heat dissipation and chip removal holes 3-1 are uniformly arranged, and the number of heat dissipation and chip removal holes 3-1 is set according to specific conditions. One end of the housing 3 is connected to the shaft II interface 4 , the other end of the housing 3 is connected to the end cover 2 , and the housing 3 is provided with the shaft I interface 1 . The shaft I interface 1, the end cover 2 and the shaft II interface 4 above all have shaft holes, the inner wall of the shaft hole of the end cover 2 is embedded with a copper sleeve I13, and the inner wall of the shaft hole at the end where the shaft II interface 4 is connected to the shaft I interface 1 is embedded. There is a copper sleeve II14, and the two ends of the shaft I interface 1 are respectively inserted into the copper sleeve I13 and the copper sleeve II14. The inner walls of copper sleeve I13 and copper sleev...

Embodiment 2

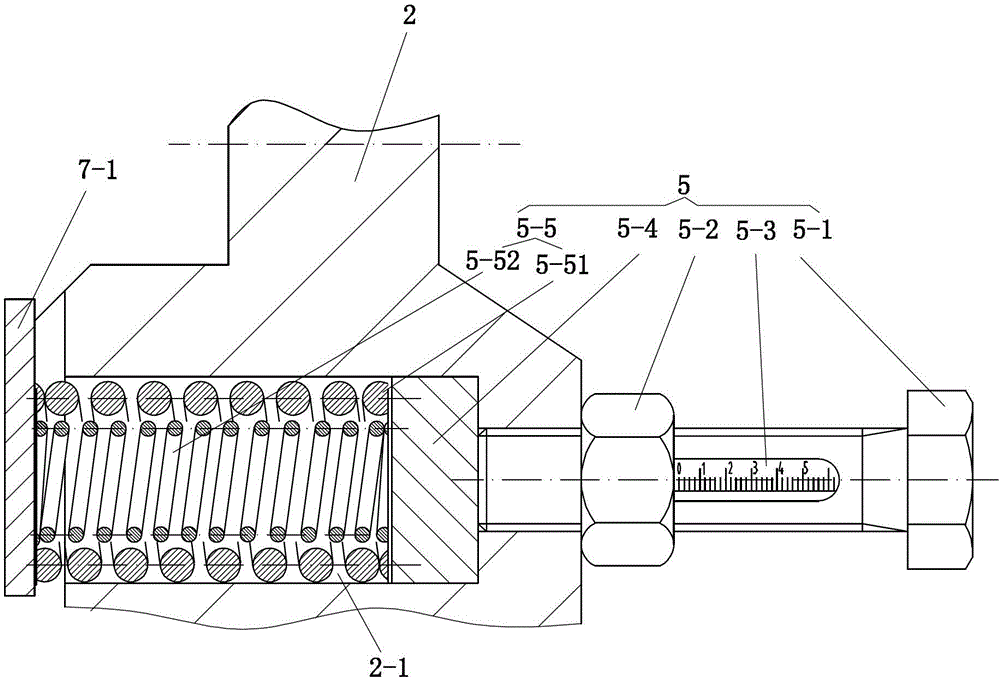

[0026] On the basis of Example 1, in Example 2, a groove is milled on the rod of the main adjusting bolt 5-1, and there is a scale value inside. During the process of tightening the main adjusting bolt to compress the spring, by observing The scale value on the main adjustment bolt adjusts the slipping torque of the safety clutch to a specified value. A groove is milled on the rod portion of the auxiliary adjusting bolt 8-1, and there is a scale value inside, and the slipping torque of the safety clutch is adjusted to a specified value by observing the scale value on the auxiliary adjusting bolt. Since the scale values are respectively marked on the rods of the main and auxiliary adjusting bolts, the quantitative adjustment of the torque can be realized, which provides further convenience for the adjustment of the torque.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com