Protective element

A technology for protecting components and heating elements, applied to electrical components, emergency protection devices, circuits, etc., can solve problems such as abnormal drop in output voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

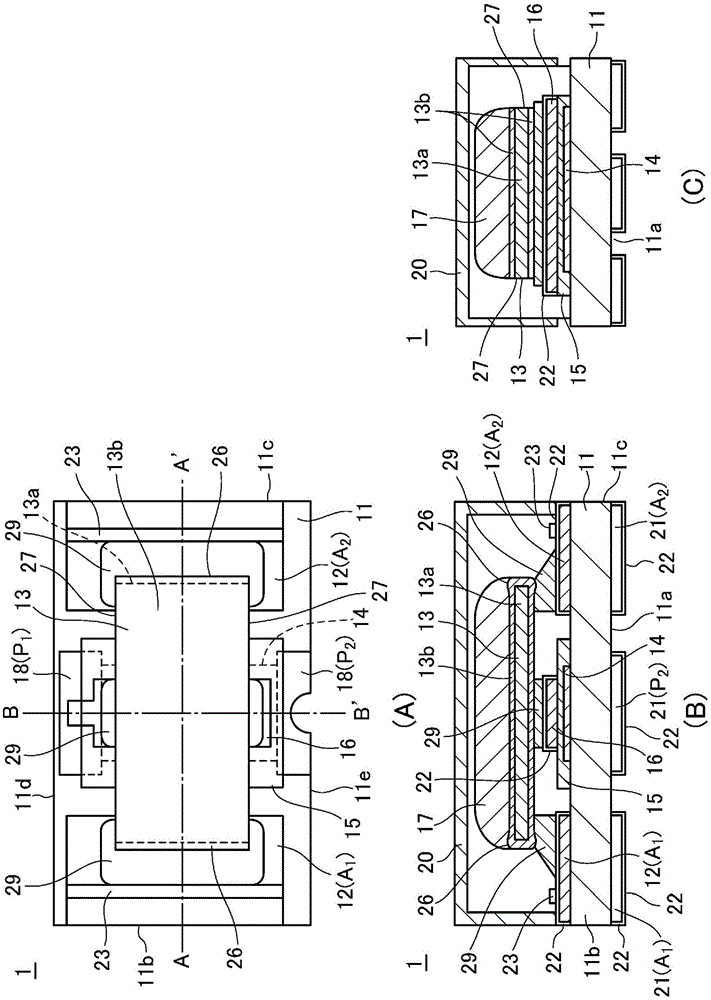

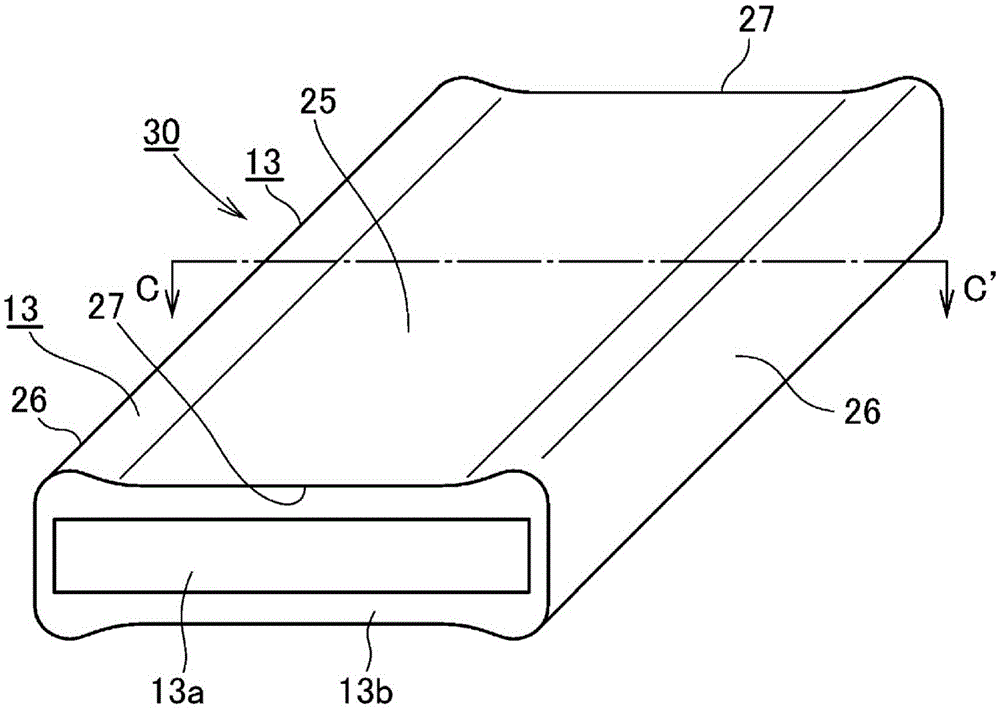

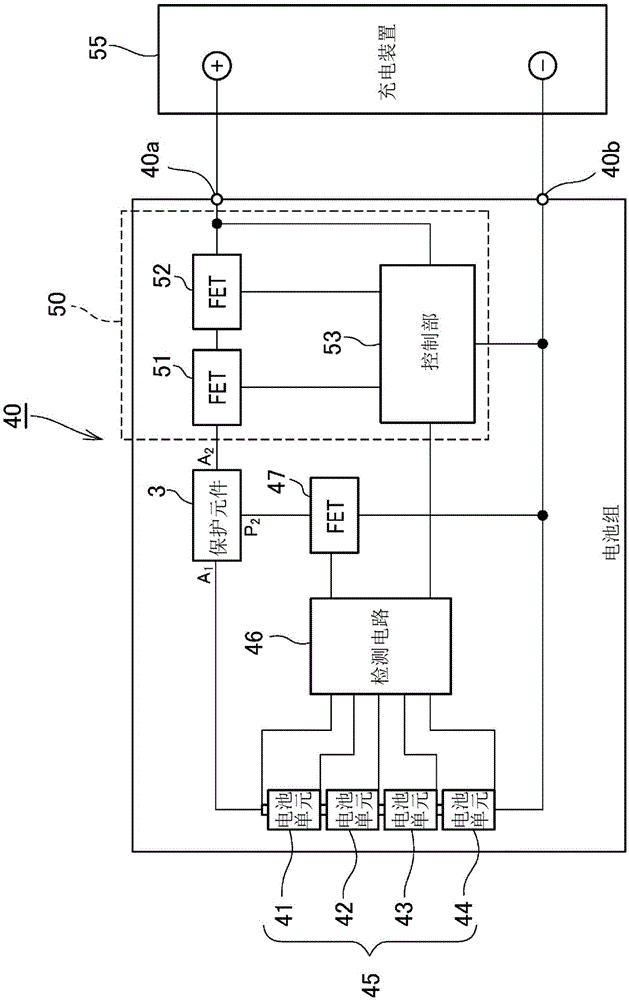

[0104] Next, a first embodiment of the present invention will be described. In the first example, a conductor strip in which a low-melting-point metal foil was coated with a high-melting-point metal by an electrolytic plating method was fabricated and cut in the width direction to obtain a soluble conductor. A Pb-free solder foil with a thickness of 60 μm was used as the low-melting-point metal foil, and the entire surface of the low-melting-point metal foil was plated with Ag by electrolytic plating to form a high-melting-point metal layer with a thickness of 4 μm on one side.

[0105] In Example 1, the first side edge portion of the soluble conductor formed to be thicker by coating with a high-melting point metal was arranged on the first electrode and the second electrode, and the cut surface of the conductor tape was The second side edge portion is arranged along a current path extending from the first electrode to the heat generating element lead-out electrode to the seco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com