Frequency-selective damper valve, and shock absorber and piston having such valve

A damping valve, shock absorber technology, applied in shock absorbers, springs/shock absorbers, shock absorbers, etc., can solve problems such as large space and application difficulties, and achieve stable performance, difficult manufacturing tolerances, and simple design. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

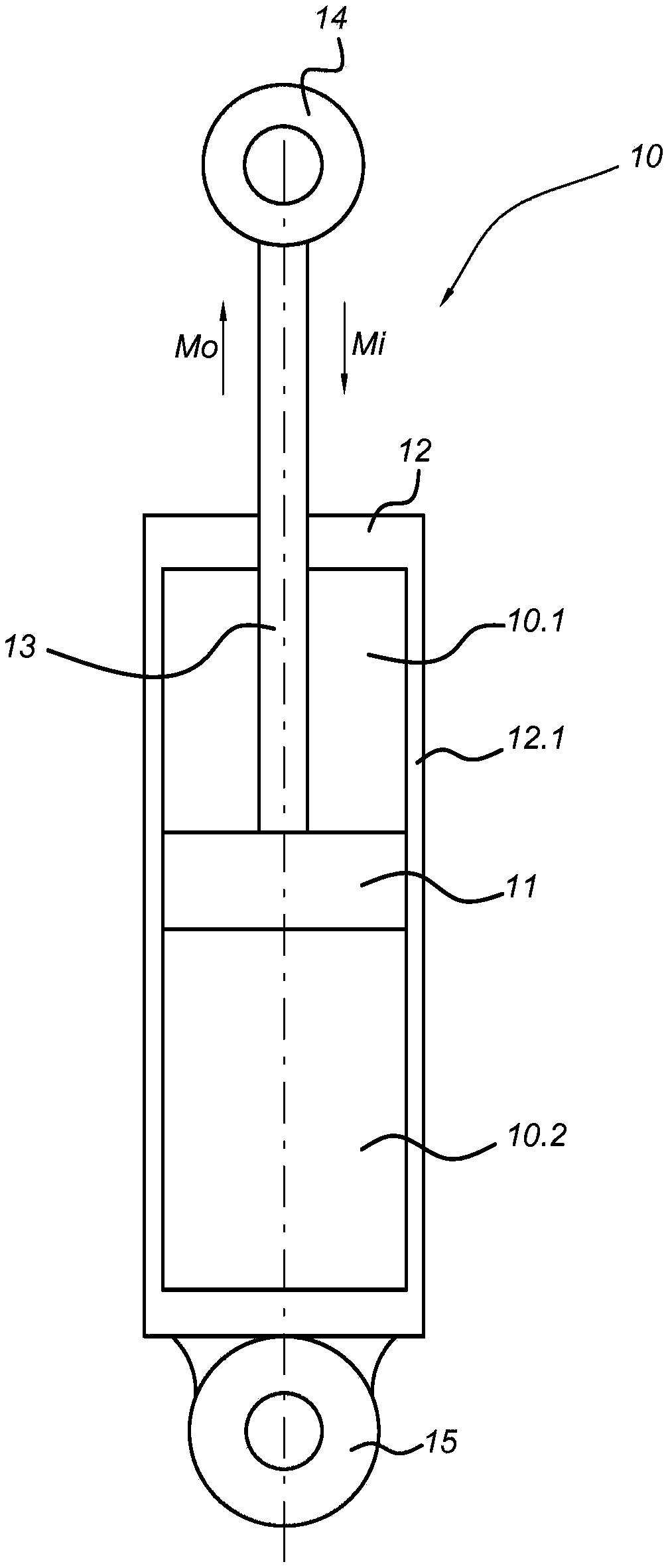

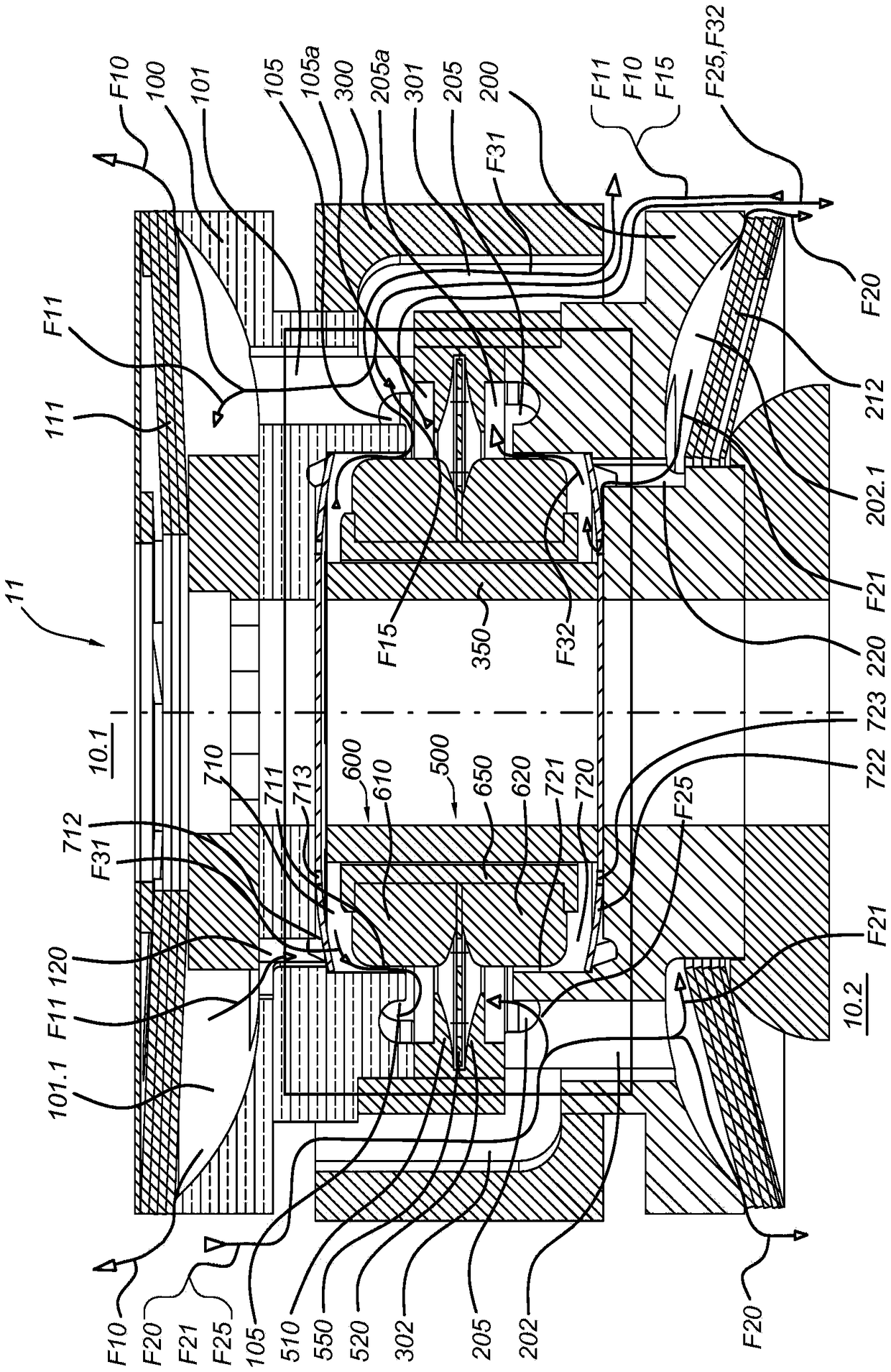

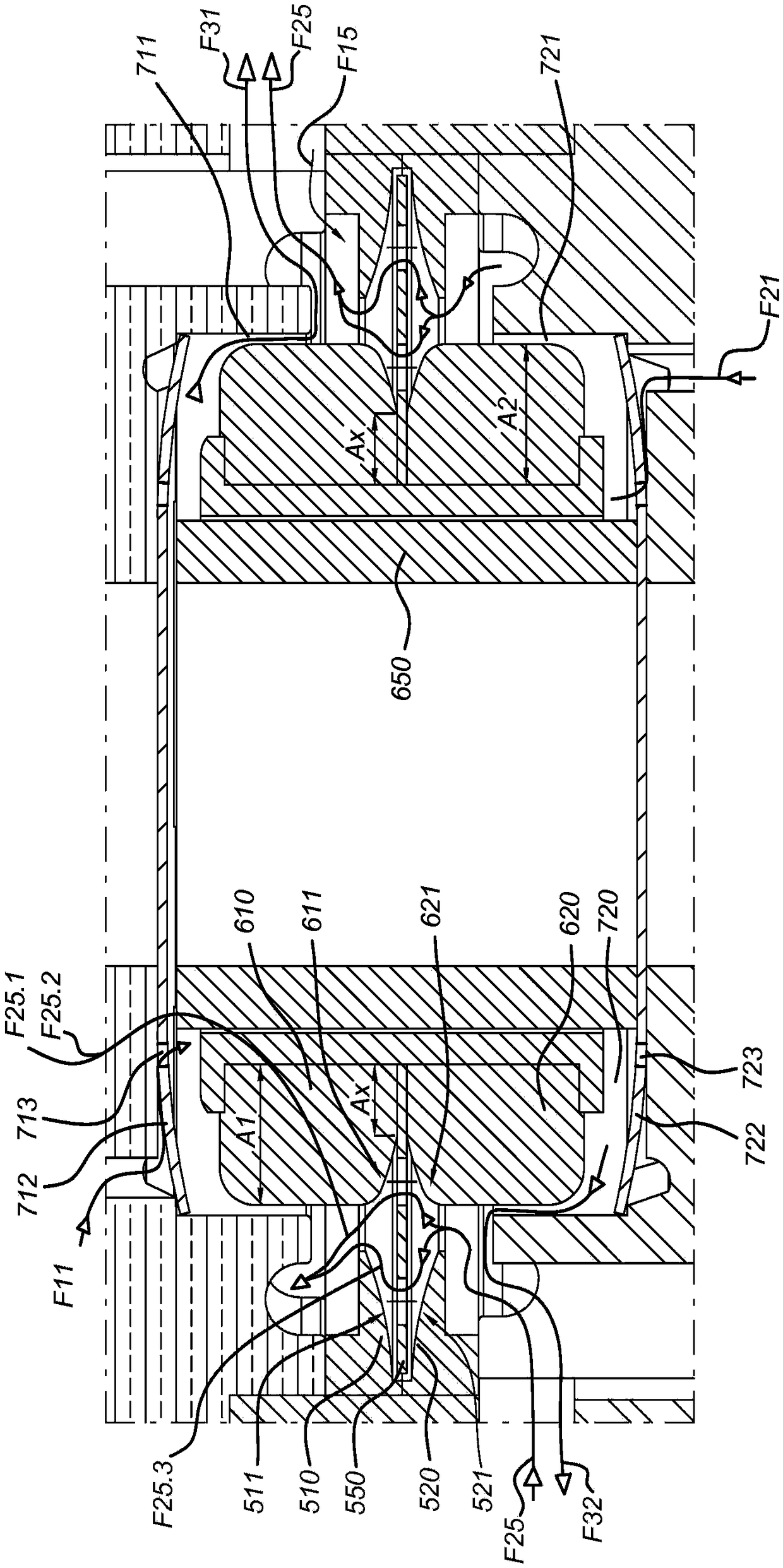

[0079] figure 1A shock absorber or damper 10 according to the invention is shown schematically. The damper includes a cylinder 12 and a piston 11 movable within the cylinder in inward and outward directions relative to the cylinder. The directions of movement of the piston's inward and outward strokes are indicated by arrows labeled Mi and Mo, respectively. The piston seals against the cylindrical wall 12.1 of the cylinder and divides the cylinder into a first or upper cylinder (damping) chamber 10.1 and a second or lower cylinder (damping) chamber 10.2. A piston rod 13 attached to the piston 11 is guided through the top wall of the cylinder 12 in a sealed manner. The damper may be attached by its piston attachment means 14 and cylinder attachment means 15 to eg a component of an automobile to damp relative motion. The damping can be achieved by, for example, the arrangement of the piston 11 influencing the fluid flow between the first cylinder chamber and the second cylind...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com