Rotary ventilating conductive seat for compressor welding

A compressor and conductive seat technology, applied in welding equipment, welding equipment, auxiliary welding equipment, etc., can solve the problems of low degree of automation, uneven welding seam, easy occurrence of pores, etc., to achieve low production cost, ensure welding effect, simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

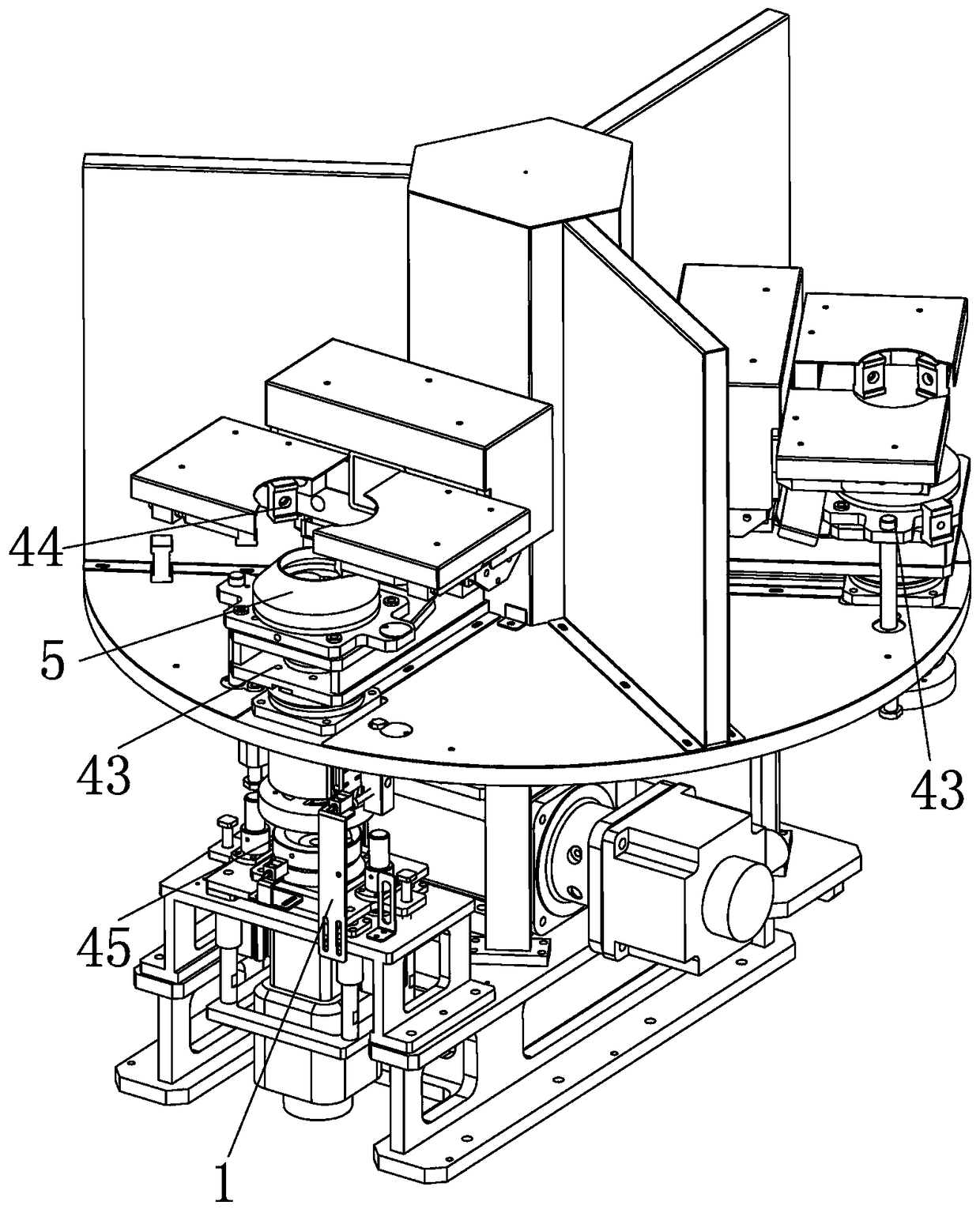

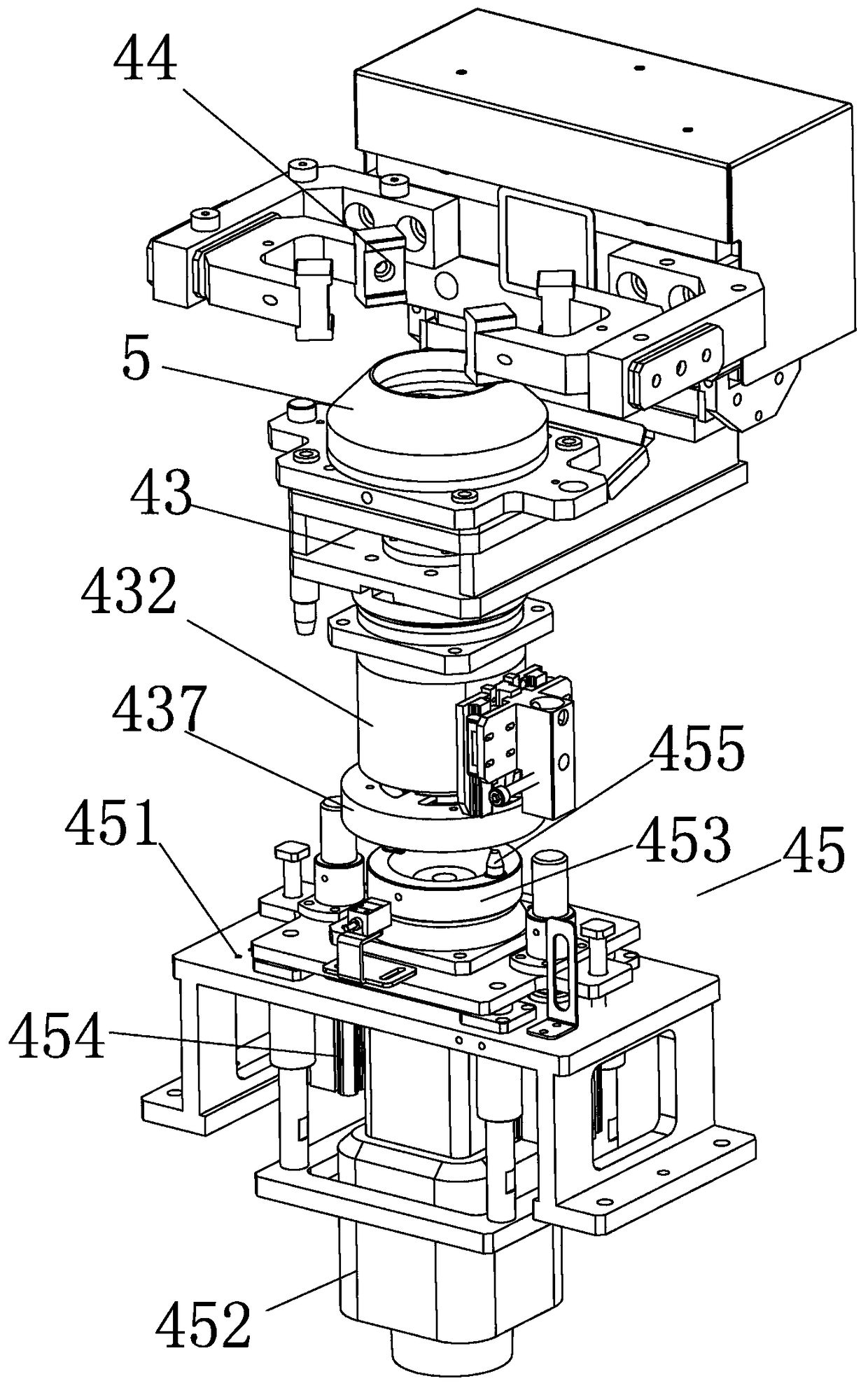

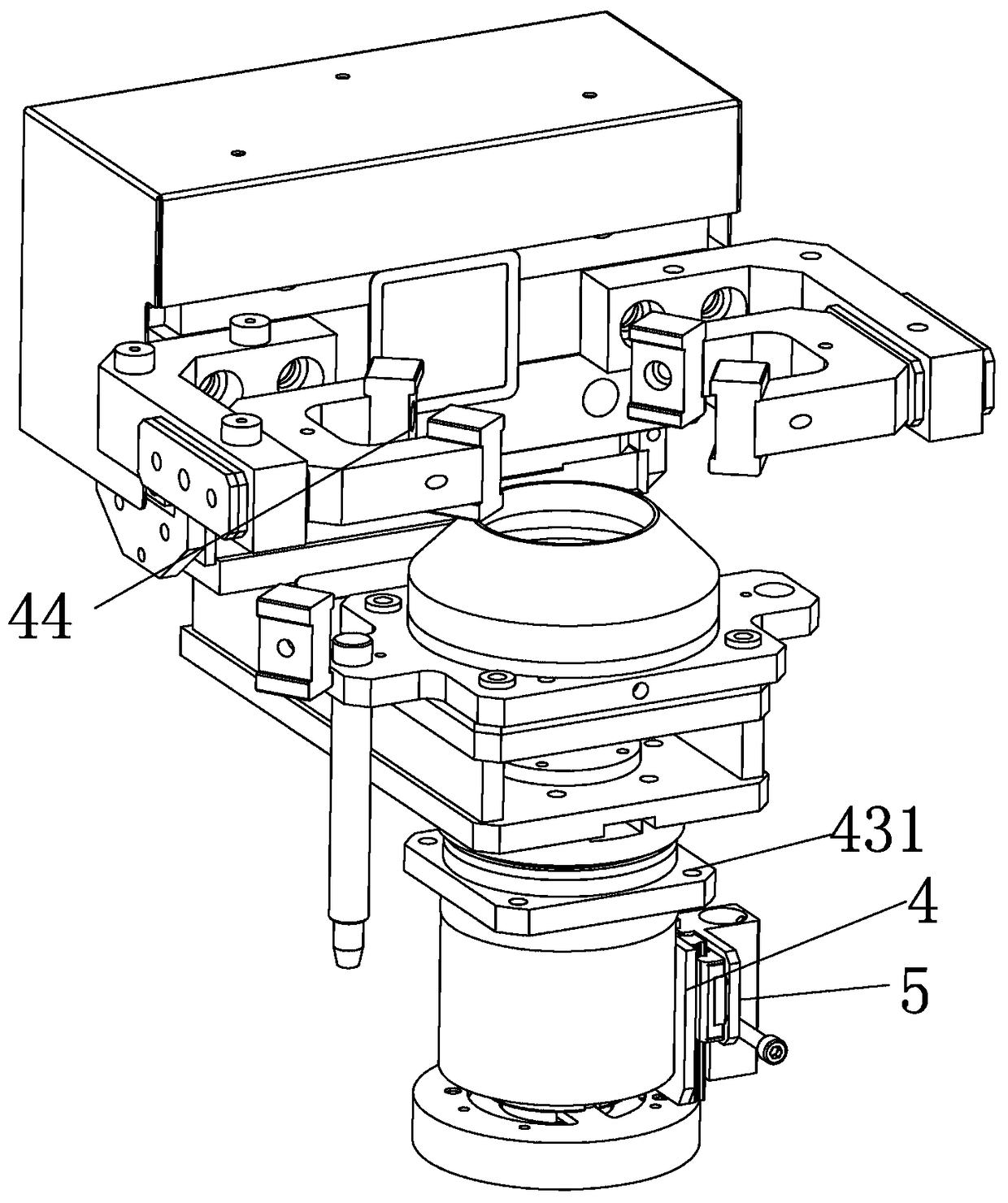

[0016] The present invention will be specifically and further described below in conjunction with the accompanying drawings. A welding rotary ventilation conductive seat for a compressor, which includes a mounting seat 431 and a rotating shaft seat 432 located at its lower end, a rotating shaft 434 is installed in the rotating shaft seat 432 through a bearing 433, and the top of the rotating shaft 434 passes through a rotating shaft connection plate 435 Installed with the positioning fixture 44, the bottom of the rotating shaft 434 is provided with a positioning disc 436, and the positioning disc 436 is docked with the jacking rotating structure 45; an electrode disc 437 is installed on the outer circumference of the positioning disc 436, and the electrode disc 437 is arranged on the rotating shaft. The conductive rod 438 in 434 is electrically connected, and the conductive rod is electrically connected with the positioning fixture 44. Correspondingly, the ground wire of the el...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com