Novel tube plate automatic welding machine tool

An automatic welding machine and tube-sheet technology, applied in welding equipment, manufacturing tools, auxiliary devices, etc., can solve problems such as incomplete welding of pipe fittings and tube-sheet welds, low tube-sheet welding efficiency, and reduced weld quality, etc., to achieve Improve the efficiency of fixed positioning, improve welding quality and welding efficiency, and facilitate adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

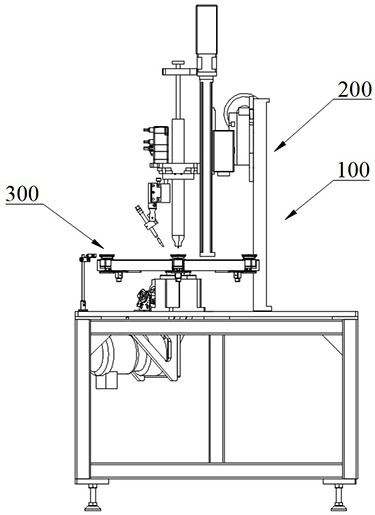

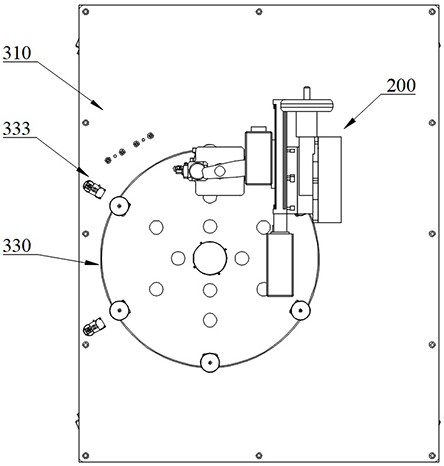

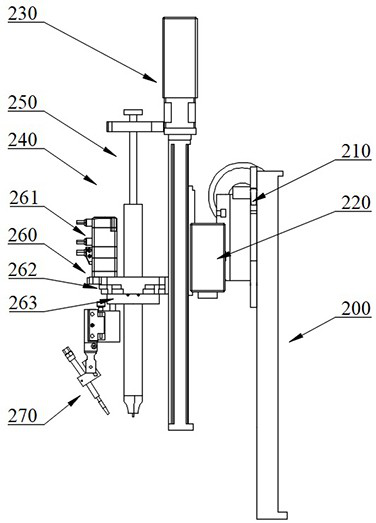

[0052] Specific examples are as follows, such as Figure 1-3Shown: a new type of automatic tube sheet welding machine tooling, the automatic tube sheet welding machine tooling 100 includes a tube sheet welding machine assembly 200, and the tube sheet welding machine assembly 200 includes a spin welding machine assembly 240; the spin welding machine assembly 240 It includes a positioning pipe 250 and an automatic rotating assembly 260 set on the positioning pipe. The lower part of the automatic rotating assembly 260 is provided with a welding torch adjusting assembly 270 that can rotate along the circumference of the positioning pipe. The welding torch adjusting assembly can be connected with the automatic rotating assembly through a connecting column. And along with the automatic rotation component rotates along the circumference of the positioning tube, so as to facilitate the automatic welding of the circumferential connection between the tube sheet and the pipe fitting; the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com