Bent sectional material pultrusion production traction device and method based on traction rate differential motion

A technology of traction equipment and profiles, applied in the field of pultrusion production traction equipment, can solve problems such as difficulties in pultrusion production, and achieve the effect of simple structure and clear movement principle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

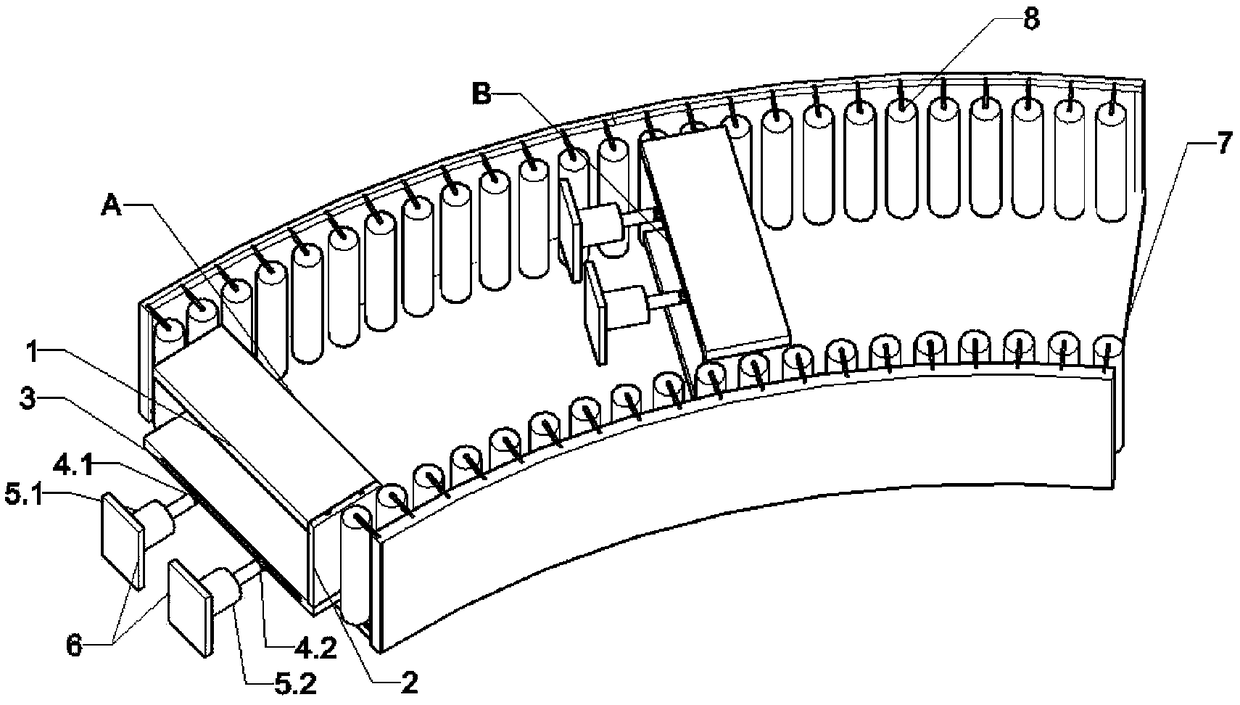

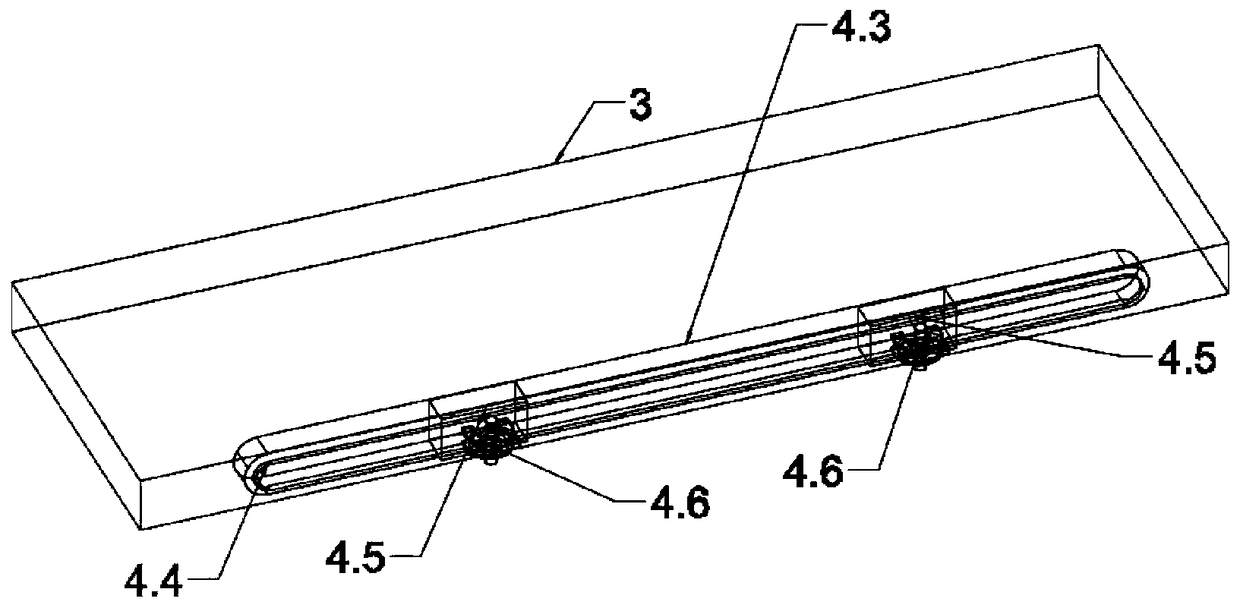

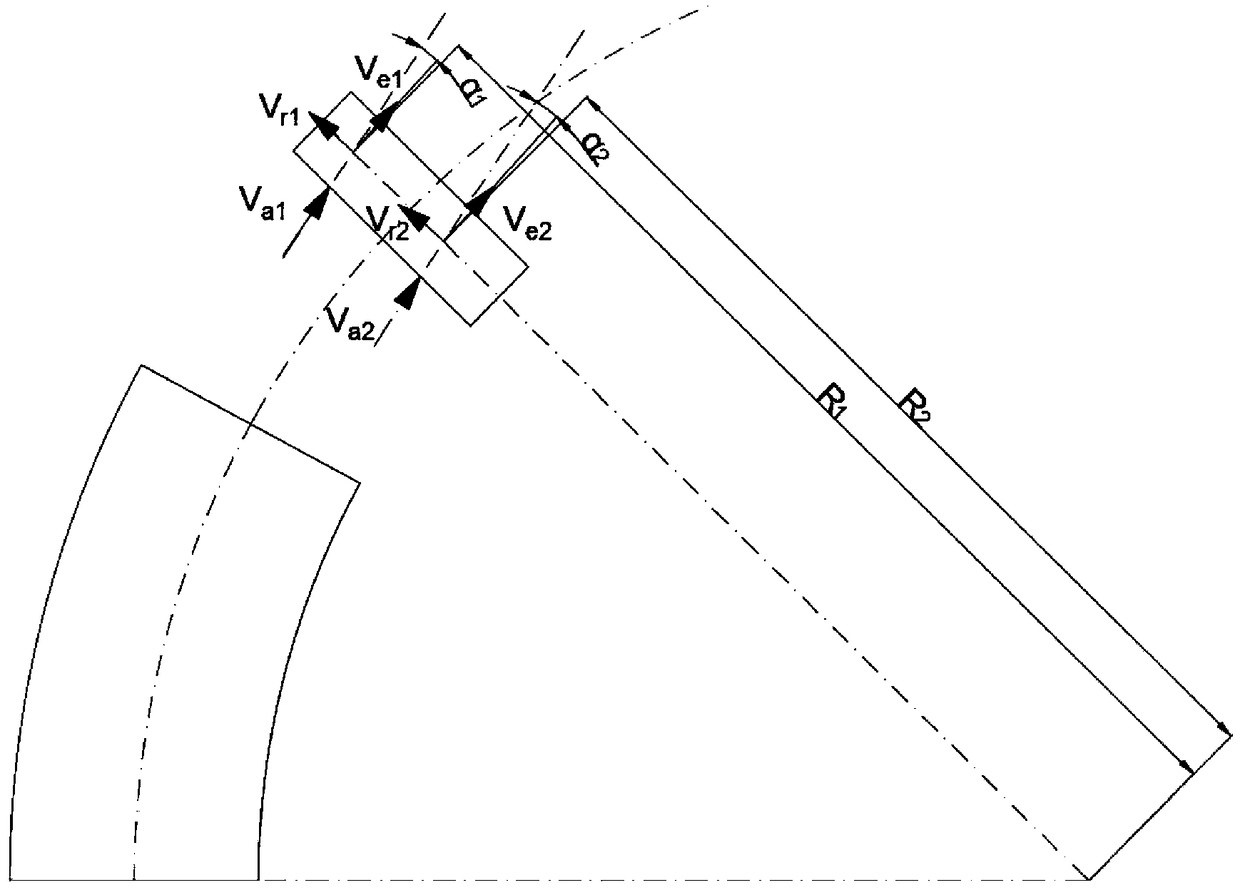

[0019] The traction equipment for the pultrusion production of the fiber reinforced composite curved profile of the present invention is as figure 1 As shown, the traction device is composed of two traction chucks and a rack rail 7, and the traction chuck is composed of a sliding splint 1, a vertical guide rail 2, a fixed splint 3, a first sliding connection 4.1, a second sliding connection 4.2, a second sliding splint A jack 5.1, a second jack 5.2 and a fixed plate 6. The sliding splint 1 can slide up and down along the vertical guide rail 2 to clamp the profile. The fixed splint 3 is connected by the first sliding connector 4.1 and the second sliding Part 4.2 is connected with the first jack 5.1 and the second jack 5.2 respectively, the sliding connecting piece can move relatively linearly along the fixed splint 3, and can rotate relative to the jack, and the jack is connected with the frame through the fixed plate 6 , to prevent the jack from sliding when pushing. The fram...

Embodiment 2

[0023] This embodiment is basically similar to Embodiment 1, and the traction chuck is slightly different, such as Figure 4As shown, a spring 9 is installed between the fixed plate 6 and the fixed splint 3 . The initial state of the spring is the state when the fixed splint is not moving. When the jack pushes the fixed splint to move in a circular curve track, the spring begins to deform. After moving to the farthest distance, the jack returns to oil, no longer applies the jacking force, and the spring begins to retract , can better drive the splint back to its original state.

[0024] According to the different curvature radii of the designed curved profiles, adjusting the size of the plywood, the curvature radius of the frame rail and the pushing speed of the two jacks can be applied to the pultrusion production of different curved profiles.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com