Rapid detection jig for automotive metal plate punched hole

A technology for detecting jigs and sheet metal. It is used in measuring devices, testing of mechanical parts, testing of machine/structural parts, etc. It can solve the problems of low work efficiency, trouble, detection errors, etc., to reduce vibration and improve accuracy. The effect of reducing the detection error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

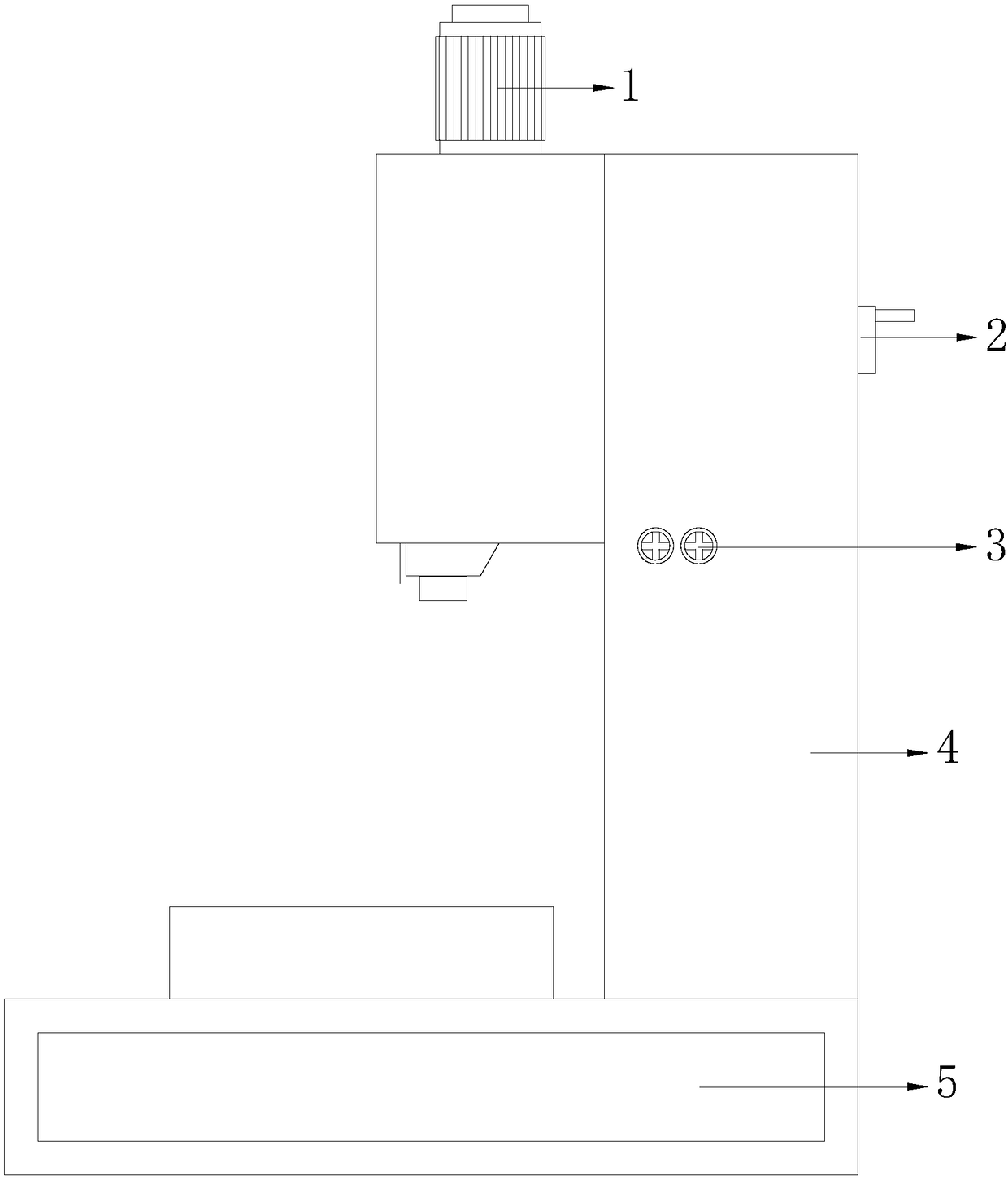

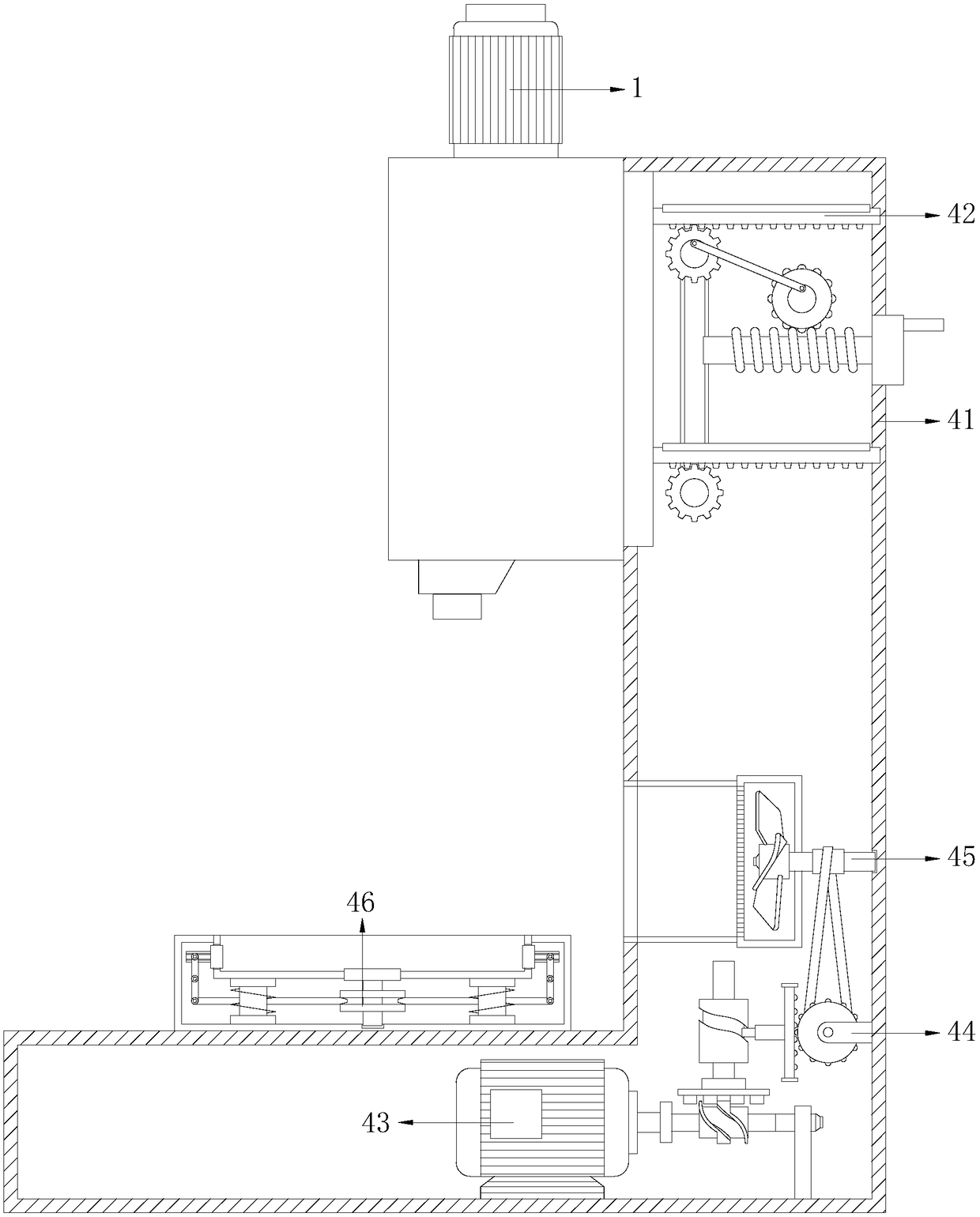

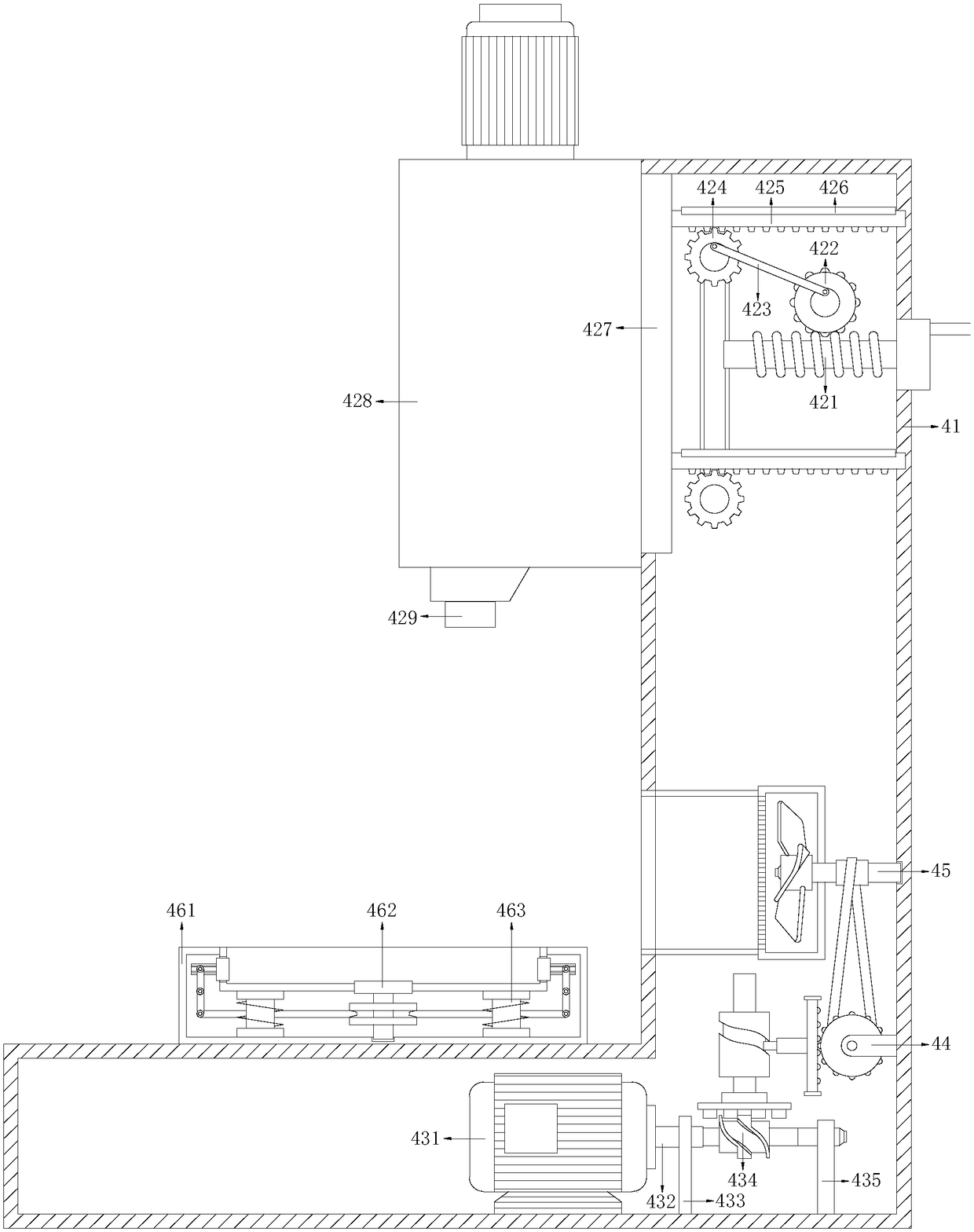

[0026] see Figure 1-Figure 6 , the present invention provides a fast detection jig for automobile sheet metal turning holes, the structure of which includes a motor 1, an adjustment disc 2, a screw 3, a detection host 4, and a maintenance door 5, and the lower end of the motor 1 is installed inside the upper end of the detection host 4 by embedding. , the adjustment disc 2 is installed inside the right end of the detection host 4 by embedding, the screw 3 is installed on the outer surface of the detection host 4 and threaded, the outer surface of the lower end of the detection host 4 is provided with a maintenance door 5, and the detection host 4 includes a casing 41, a detection and adjustment mechanism 42, a power mechanism 43, a transmission mechanism 44, a dust removal mechanism 45, and a placement mechanism 46.

[0027] The upper end of the housing 41 is provided with a detection and adjustment mechanism 42, the detection and adjustment mechanism 42 is welded and mechani...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com