Horizontal auxiliary file correction device for filing and cutting training

A file and file cutting technology, which is applied in the field of file level auxiliary correction devices for file cutting training, can solve the problems of small deflection angle of file feeding, insignificant changes of bubble meter, unsatisfactory file cutting training, etc., and achieve accurate feeding direction , good training effect, easy to promote and use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

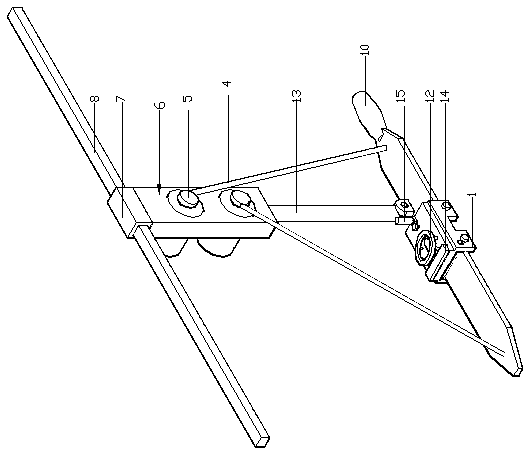

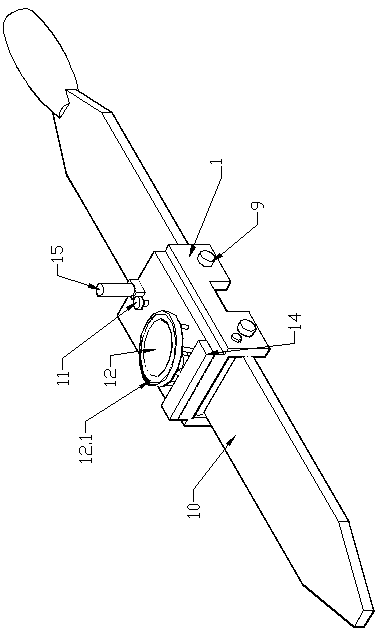

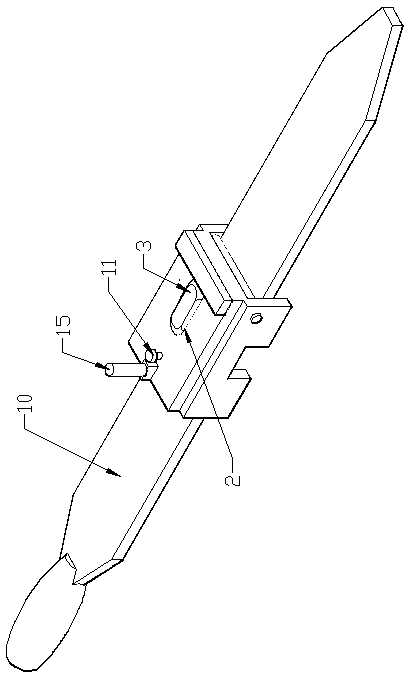

[0021] Such as Figure 1-4 As shown, the file level auxiliary correction device for file training of the present invention includes an I-shaped clamping seat 1, a bubble seat 2, a horizontal bubble meter 3, a tension rope 4, a stepping motor 5, a mounting seat 6, and a sliding seat 7. Slide rail 8, in which a bubble seat 2 is fixed on the clamping seat 1 in an embedded manner and the clamping seat 1 is fixed to the file 10 by a clamping bolt 9, and a horizontal bubble meter is fixed on the bubble seat 2 in an inlaid manner 3; On the top of the clamping seat 1 is also fixed with an adjustment bolt 11 for adjusting the bubble seat 2 in a threaded manner. The bottom of the adjustment bolt 11 is welded to one end of the bubble seat 2, and the other end of the bubble seat 2 is hinged with the clamping seat 1. ; Above the horizontal bubble meter 3 is fixed a magnifying glass 12, the magnifying glass 12 is fixed on the top surface of the clamping seat 1 through the bracket 12.1, the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com