Push-pull type door and window sash positioner

A technology of door and window sash and locator, which is applied to door/window accessories, wing sash components, and suspension devices of wing sashes, etc. The effect of thrust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

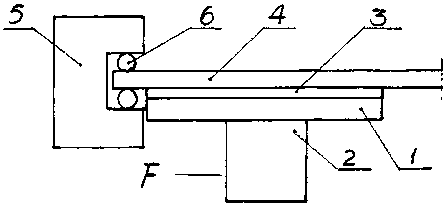

Embodiment 1

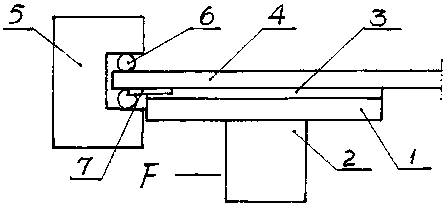

[0029] A push-pull door and window sash positioner described in Embodiment 1 of the present invention (see figure 2 ), it is composed of a slatted track 1 with a groove and a positioning body 2 installed on the track 1, and an adhesive layer 3 is set on the outer side of the positioning body 2, and the end of the positioning body 2 is set with the track 1 groove matching bolt fasteners (not shown in the figure), the positioning body 2 and the track 1 are locked and positioned by the bolt fasteners. The rail 1 and the positioning body 2 are made of ABS hard plastic, and one end of the rail 1 is fixed by bonding (it can also be any one of welding, riveting or screw fastening connection) and the overlapping section is composed of a metal sheet The anti-tipping plate 7, as the anti-tipping mechanism of the track 1, can use the compressible elasticity of the door and window sealing strip 6 when installing the push-pull door and window sash positioner, and the anti-tipping plate 7 ...

Embodiment 2

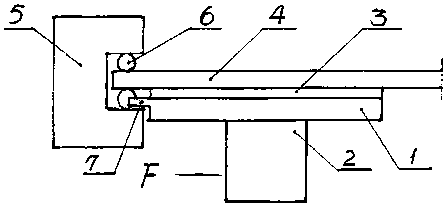

[0032] A push-pull door and window sash positioner described in Embodiment 2 of the present invention (see image 3 ), it is composed of a slatted track 1 with a groove and a positioning body 2 installed on the track 1, and an adhesive layer 3 is set on the outer side of the positioning body 2, and the end of the positioning body 2 is set with the track 1 groove matching bolt fasteners (not shown in the figure), the positioning body 2 and the track 1 are locked and positioned by the bolt fasteners. The material of the track 1 and the positioning body 2 is processed by metal materials, and one end of the track 1 is directly extended through processing to set a section of anti-tipping plate 7 composed of thin metal sheets, and the anti-tipping plate 7 is used as the anti-tipping mechanism of the track 1 When installing the push-pull door and window locator, the door and window sealing strip 6 can be used to have compressible elasticity, and the anti-lifting plate 7 can be insert...

Embodiment 3

[0035] A push-pull door and window sash positioner described in Embodiment 3 of the present invention (see Figure 4 ), it is composed of a slatted track 1 with a groove and a positioning body 2 installed on the track 1, and an adhesive layer 3 is set on the outer side of the positioning body 2, and the end of the positioning body 2 is set with the track 1 groove matching bolt fasteners (not shown in the figure), the positioning body 2 and the track 1 are locked and positioned by the bolt fasteners. The track 1 is formed by injection molding of ABS hard plastic, and the positioning body 2 is formed by die-casting of stainless steel. The anti-lifting pressing plate 8 is a flat metal thin plate, which is provided with a through hole and can be fixedly installed on the inner side of the outer door and window frame body 5 by screws, and is fixedly installed on the outer side of the track 1 on the door and window glass 4. Adhere to each other, as a non-connected anti-lifting mecha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com