A SICM probe-sample distance control method and system

A probe and distance technology, applied in the field of scanning ion conductance microscopy imaging, can solve the problems of tailing, large current deviation, different speeds, etc., to avoid oscillation, speed up the response speed, and easy to shape the effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be described in further detail below in conjunction with the accompanying drawings.

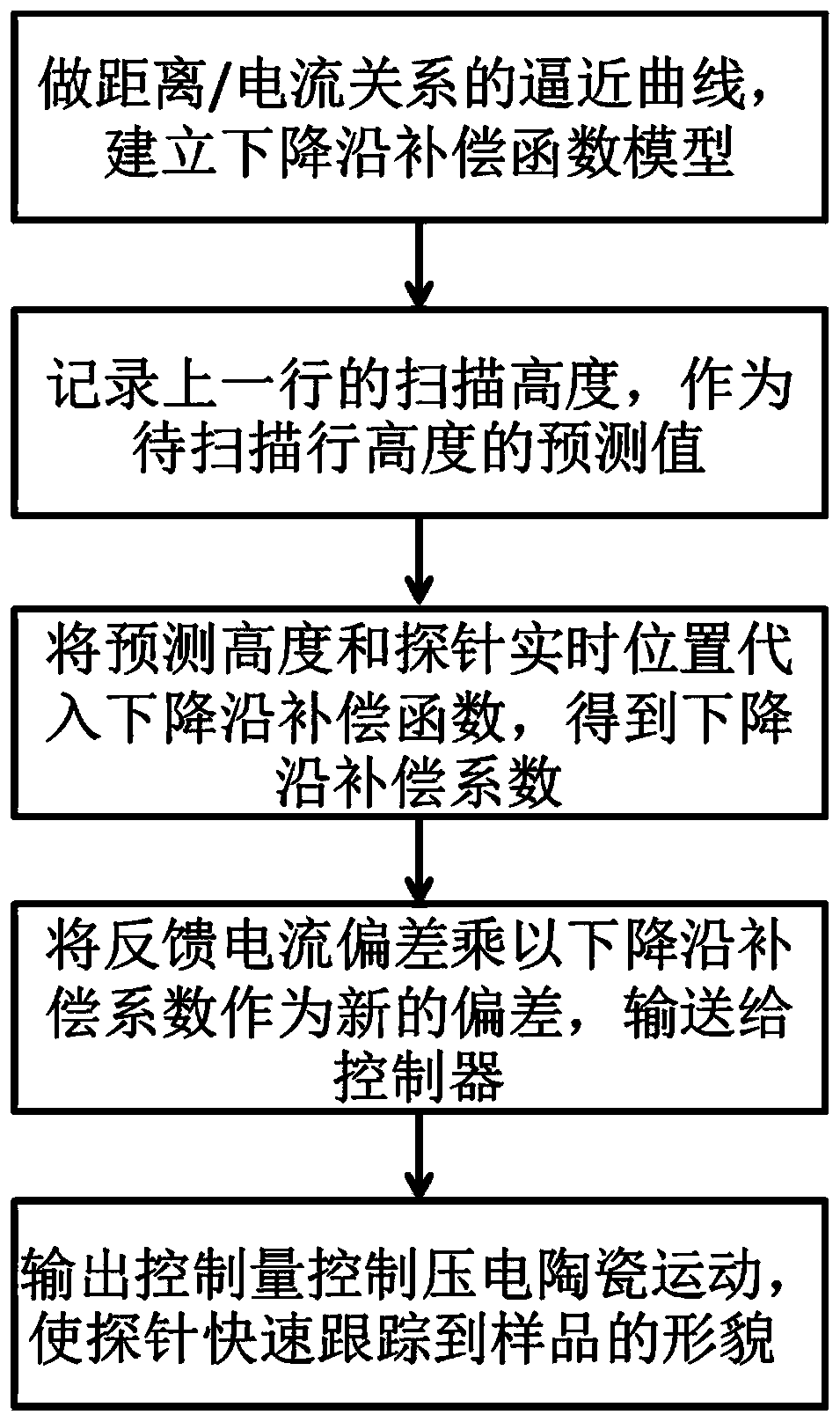

[0046] A method for adaptively controlling the distance between a SICM probe and a sample, comprising:

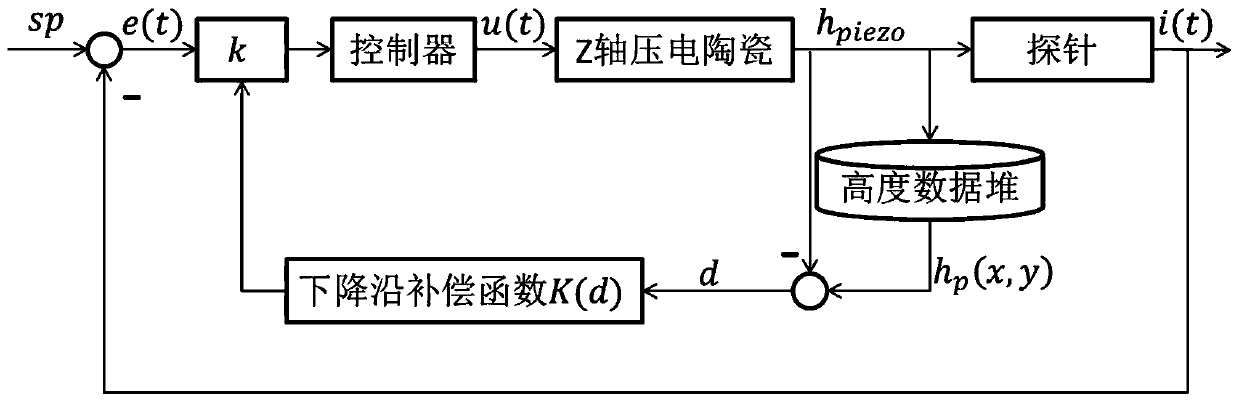

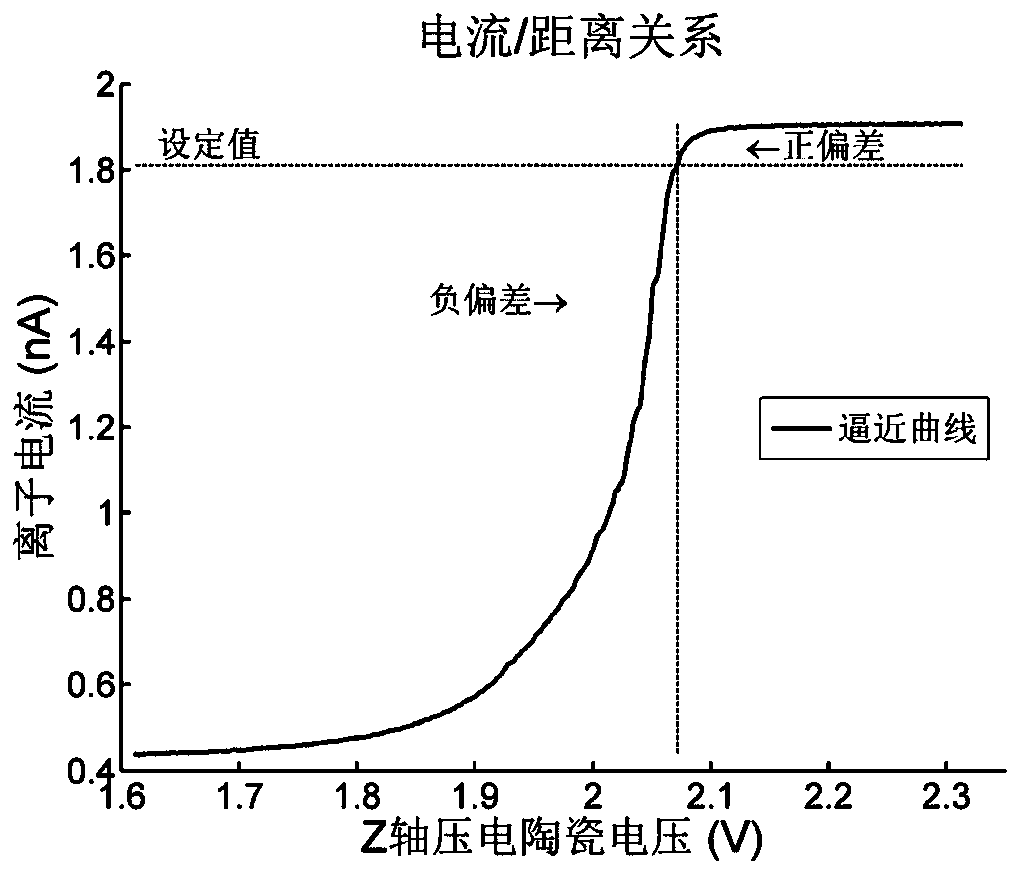

[0047] Step 1. Make an approximation curve before starting scanning. The approximation curve is the relationship curve between the probe / sample distance and the ion current. Use the approximation curve to establish a falling edge compensation function model. The model uses the Z of the current position of the probe and the position of the working point The voltage difference of the axial piezoelectric ceramic is the input, and the output is the ratio of the current deviation between the rising edge and the falling edge corresponding to the same distance;

[0048] Step 2. During the scanning process, record the scanning height of the previous line of the image as the predicted height of the current line to be scanned;

[0049] Step 3. When scanning the cur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com