Furniture machining table bed

A technology for processing tables and furniture, applied in wood processing appliances, manufacturing tools, multi-purpose machinery, etc., can solve the problems of the influence of the operating table, inconvenient movement, and the position of the operating table cannot be adjusted, and achieves a labor-saving angle and a large scope of application. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

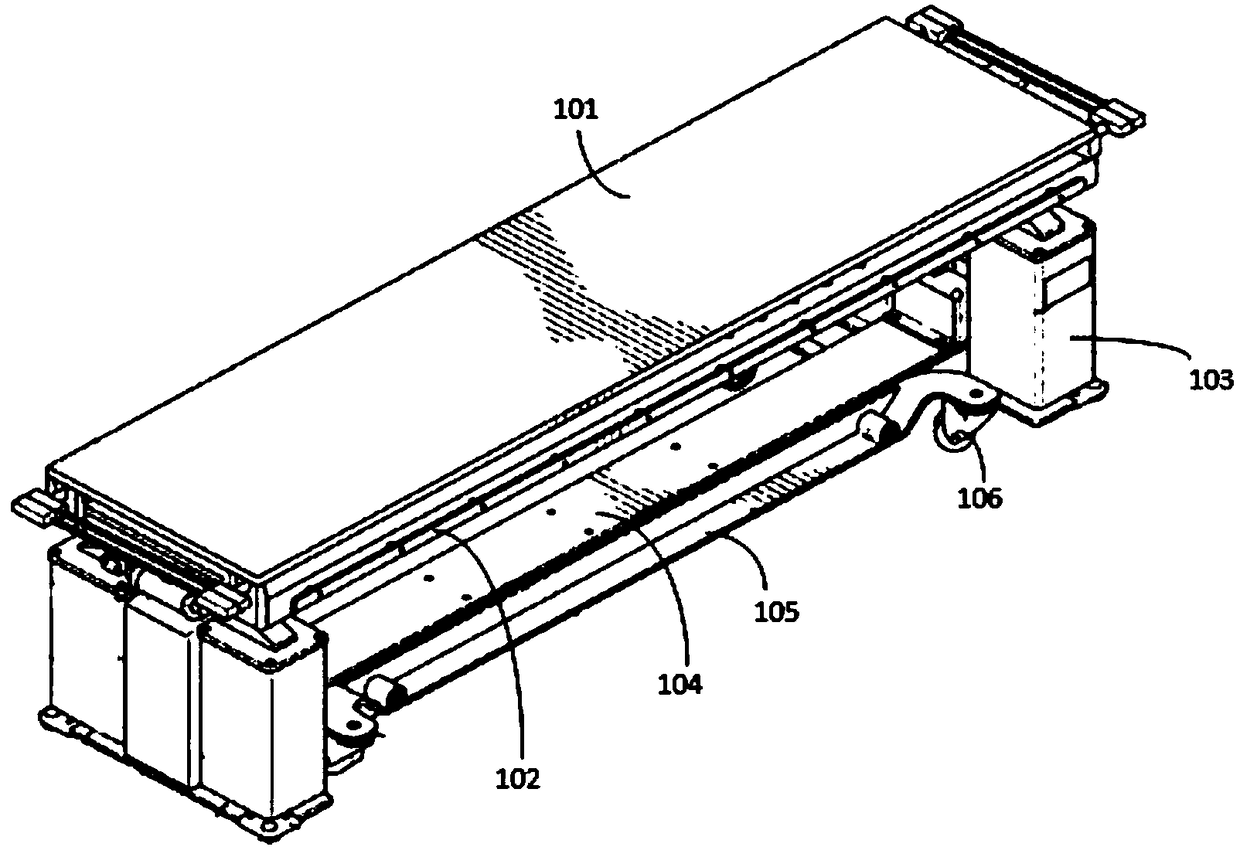

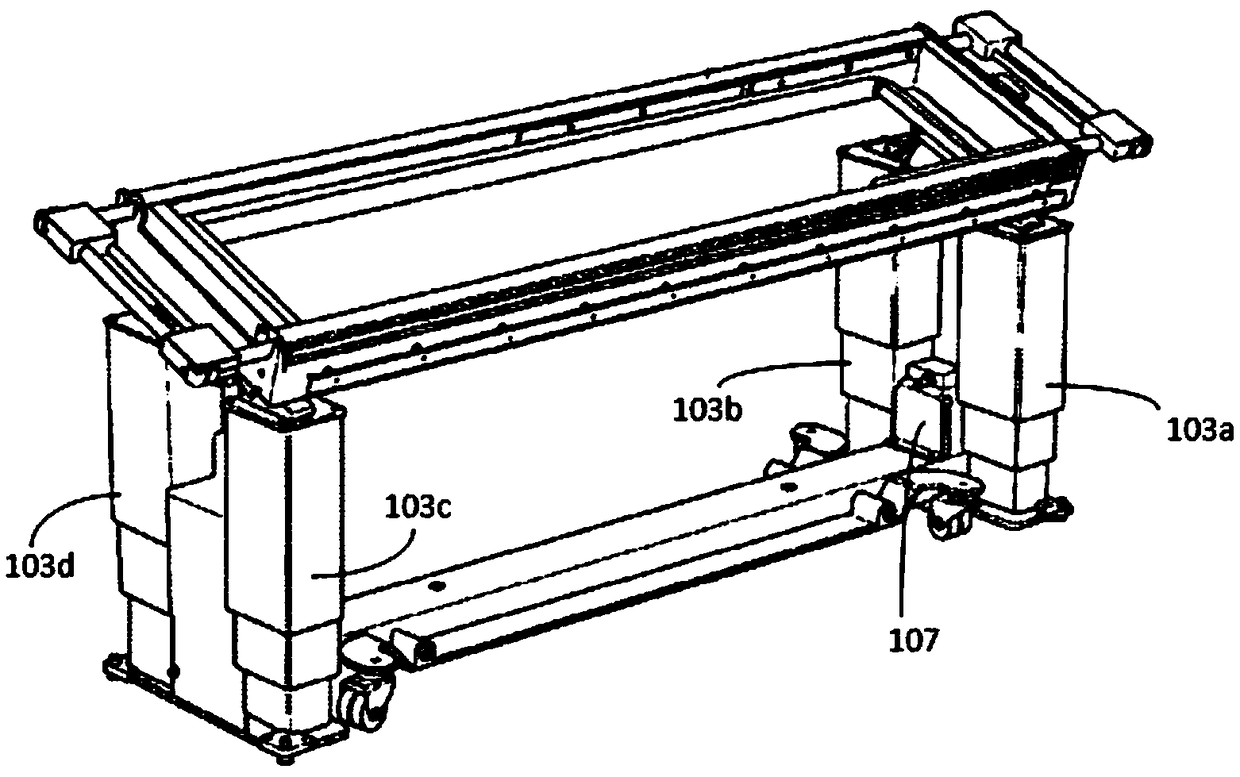

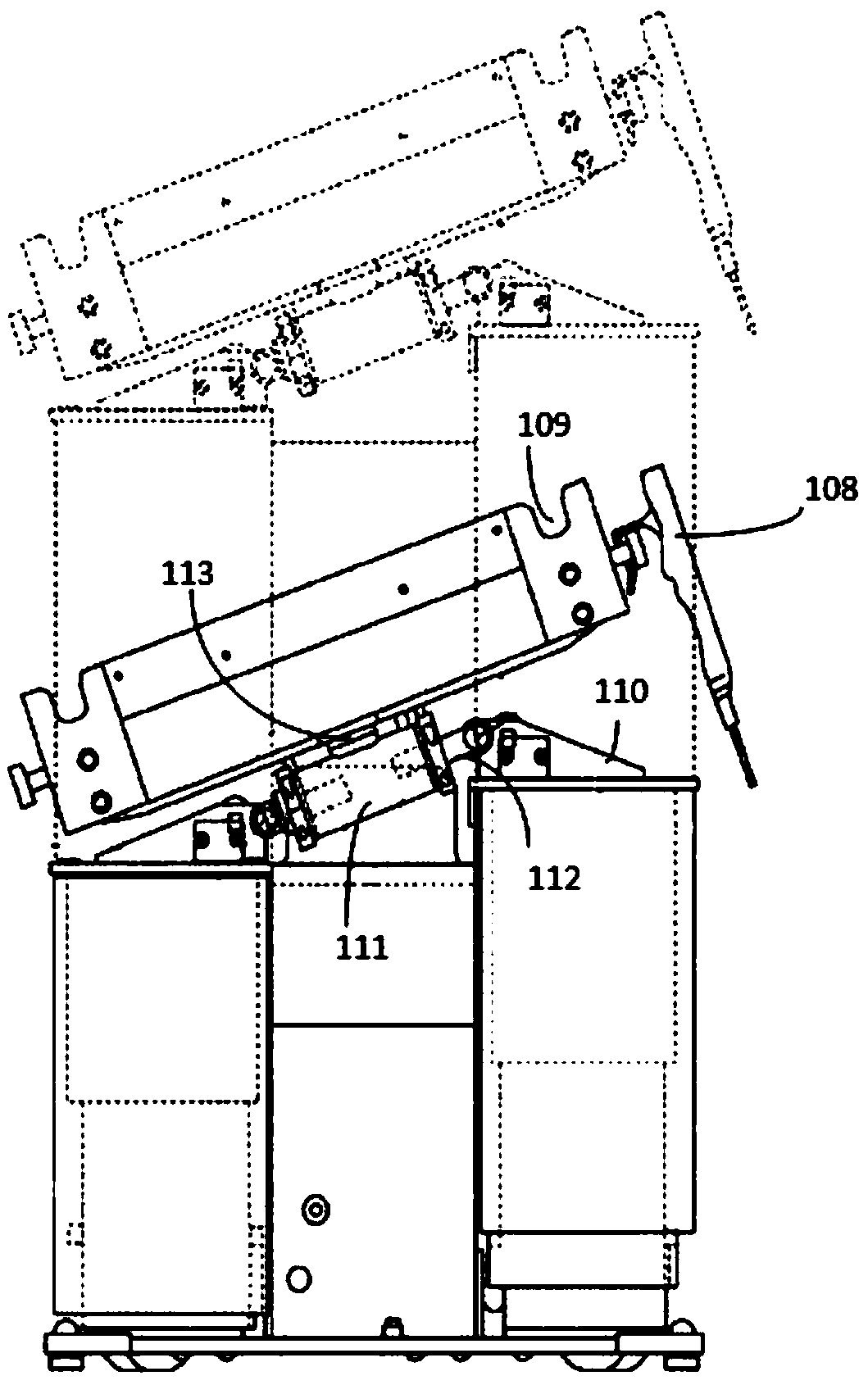

[0024] A furniture processing bed, such as figure 1 , figure 2 , image 3 , Figure 4 with Figure 5 Shown. The furniture processing bed includes at least an operating table 101 and a supporting leg 103. The operating table 101 is used as a workbench for cutting, drilling, and engraving operations during the processing of furniture panels. The supporting feet 103 are used for supporting the furniture processing table bed and adjusting the position of the operating table 101.

[0025] Preferably, the supporting foot 103 is connected to the operating table 101 to complete the support for the operating table 101.

[0026] Preferably, the supporting legs 103 include a first supporting leg 103a, a second supporting leg 103b, a third supporting leg 103c, and a fourth supporting leg 103d, that is, supporting the operating table 101 is completed by four supporting legs 103.

[0027] Preferably, the first supporting leg 103a and the second supporting leg 103b are located at one end of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com