Multifunctional jig for metal implanting and product withdrawal

A product extraction and multi-functional technology, applied in coating and other directions, can solve the problems of long injection molding cycle, hidden safety hazards, and low labor efficiency, and achieve the effect of shortening the injection molding cycle and preventing safety accidents.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

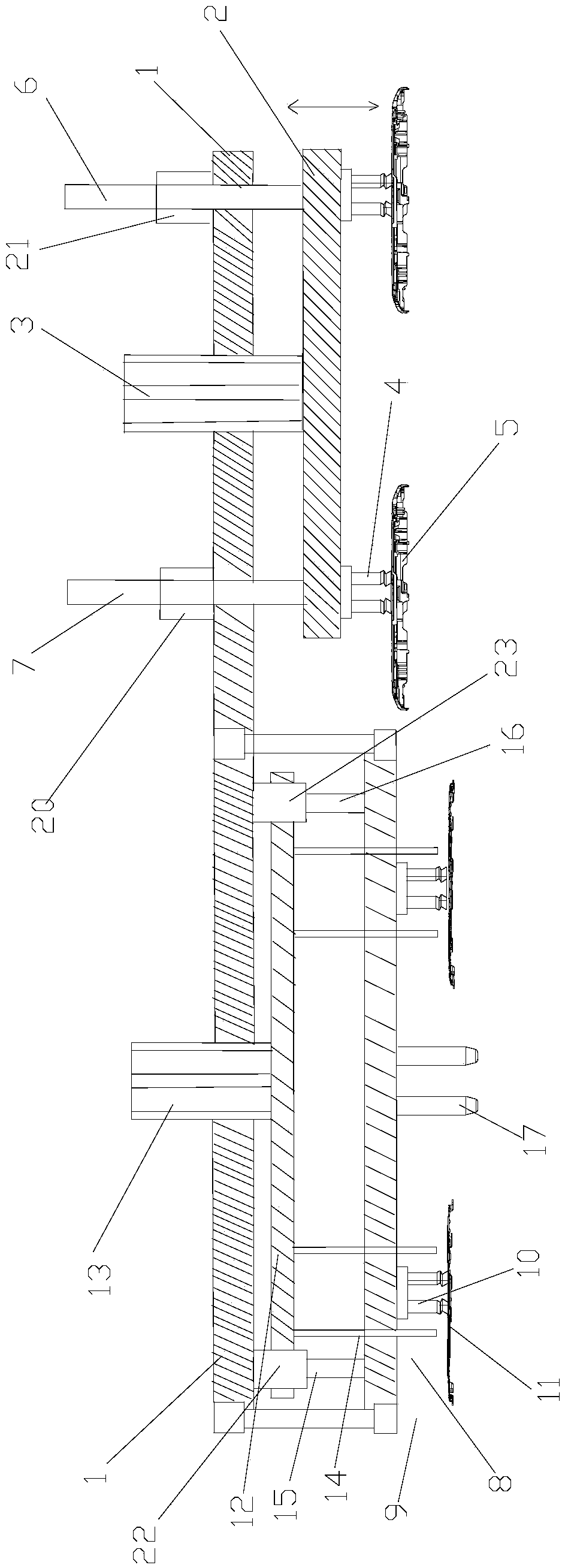

[0027] like figure 1 , a multifunctional jig for metal implantation and product removal, the jig includes a grasping jig, the grabbing jig includes a base 1, and the base 1 is provided with two parts of the mechanism, which are the product suction mechanism and the Metal sheet implant mechanism;

[0028] The product suction mechanism includes a first panel 2. The first panel 2 is located on the lower side of the base 1. A first cylinder 3 is arranged on the upper side of the base 1. The first cylinder 3 passes through the inside of the base 1 and is connected to the first panel 2. The first panel 2 The upper is fixedly provided with a first suction cup 4;

[0029] The metal sheet implantation mechanism includes a second panel 8, on which four support columns 9 are fixedly arranged, and the support columns 9 are connected to the lower side of the base 1, and a top plate 12 is arranged in the middle of the second panel 8 and the base 1, and the base 1 The upper side is provide...

Embodiment approach

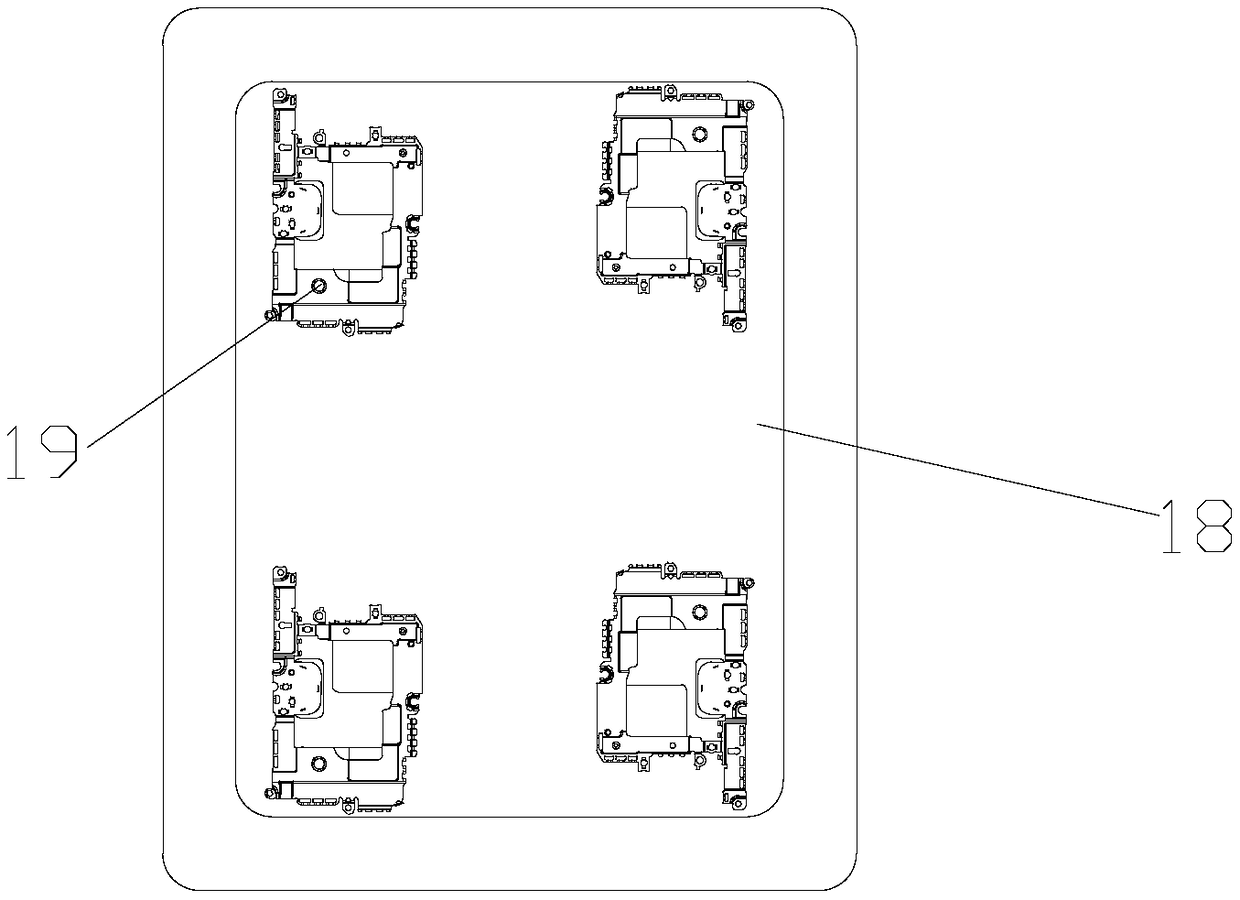

[0031] like figure 2 As shown, the jig also includes a positioning jig 18, a metal piece is placed on the positioning jig 18, a circular positioning bump 19 is arranged on the upper surface of the positioning jig 18, a positioning circular hole is provided on the metal piece, and the circular positioning bump 19 is clamped inside the positioning round hole, and the positioning jig 18 and the grasping jig are used in conjunction. The position is placed well; the principle is: a circular positioning bump 19 is set on the positioning jig 18, and a corresponding round hole is opened on the metal piece. Just place it accordingly.

[0032] like figure 1As shown, a first guide post 6 and a second guide post 7 are fixedly arranged on the first panel 2, a first bushing 20 and a second bushing 21 are fixedly arranged on the upper side of the base 1, and the first guide post 6 passes through the base 1 is movably arranged inside the first bush 20, the second guide column 7 is movably...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com