An external induction heating device for a vertical injection mold

An induction heating device and injection mold technology, which is applied in the field of external induction heating device and temperature control heating device, can solve the problems of high thermal conductivity of mold materials, inability to meet temperature requirements, and affect the quality of injection molding products, so as to shorten injection molding Effects of cycle, novel structure and ingenious design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described below with reference to the accompanying drawings and specific preferred embodiments, but the protection scope of the present invention is not limited thereby.

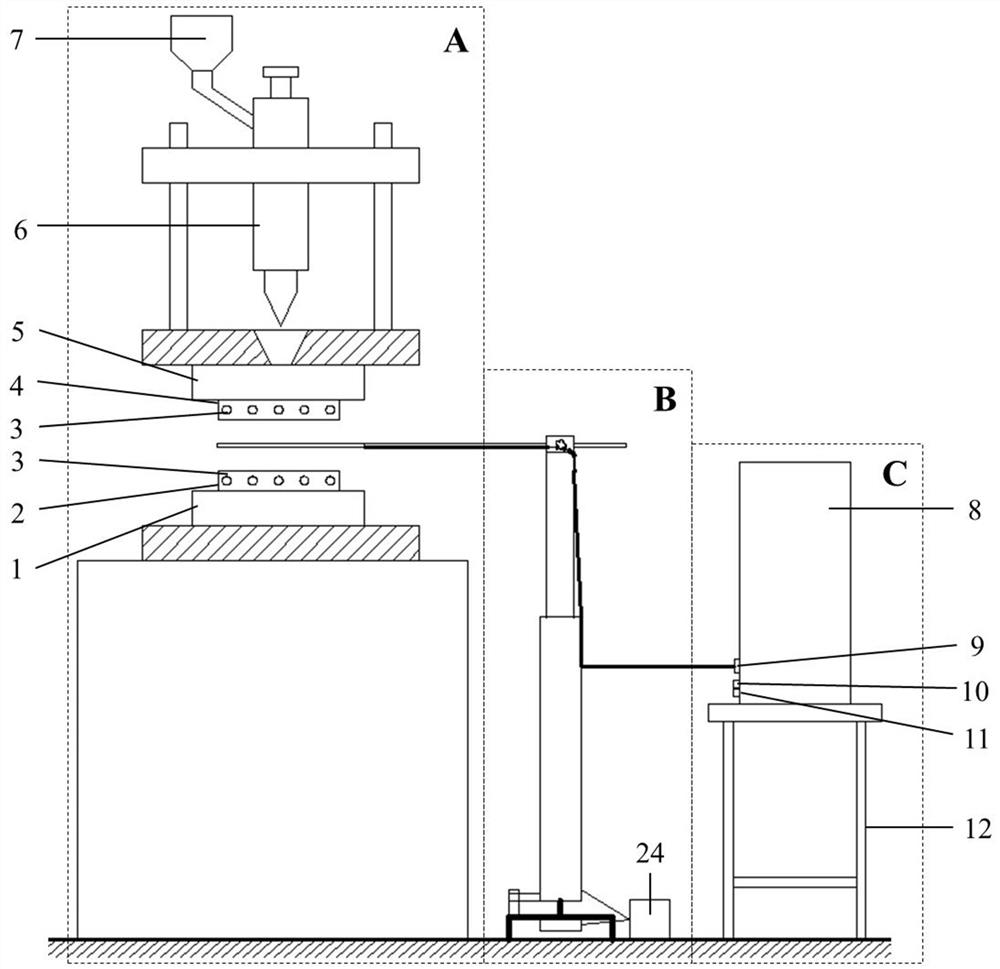

[0039]An external induction heating device for a vertical injection mold, such as Figure 1-6 As shown, it includes an injection molding device A, a clamping device B and a high-frequency heating device C, wherein the injection molding device A includes an injection mold, an injection molding machine 6 and a hopper 7, and the hopper 7 is arranged above the injection molding machine 6, and the injection molding machine 6 is fixed on the Above the injection mold, the injection mold is placed vertically, including a cavity 4, a cavity fixing plate 5, a core 2 and a core fixing plate 4, and a cooling pipe 3 is also provided on the cavity 4 and the core 2. , and cooling water flows in the cooling pipe 3 .

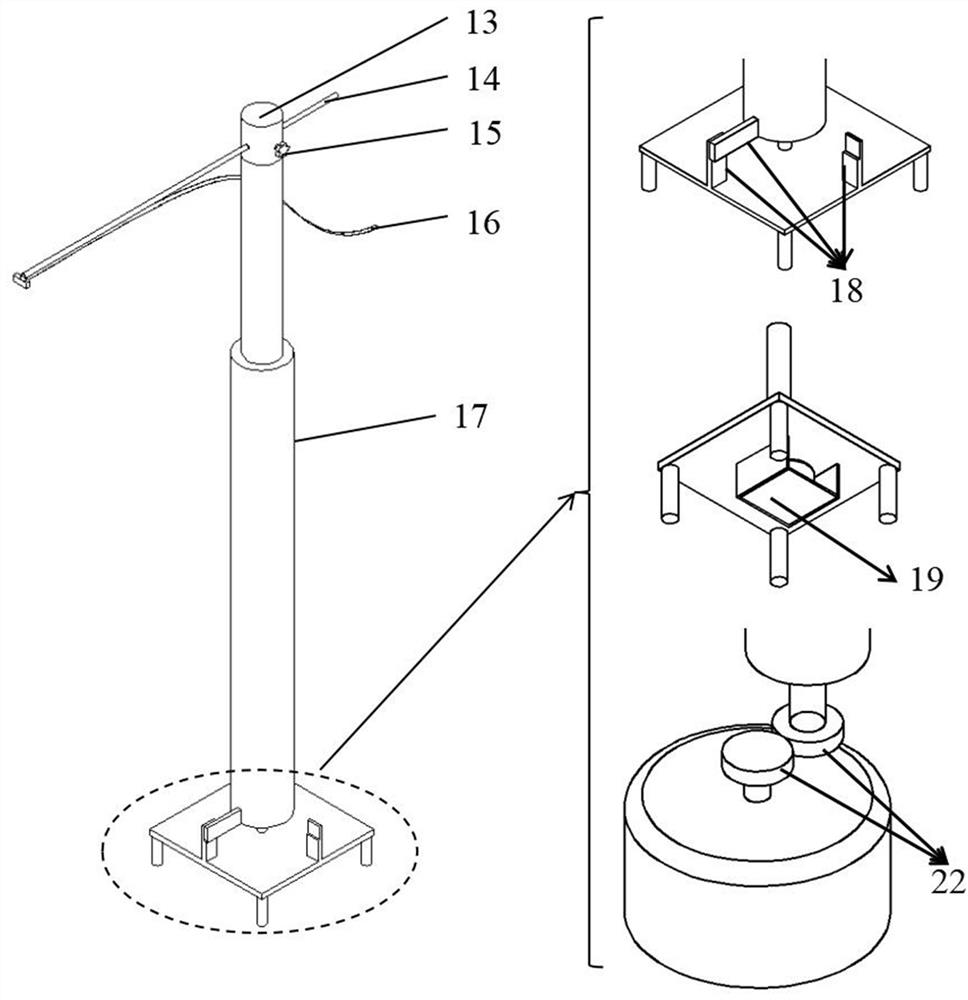

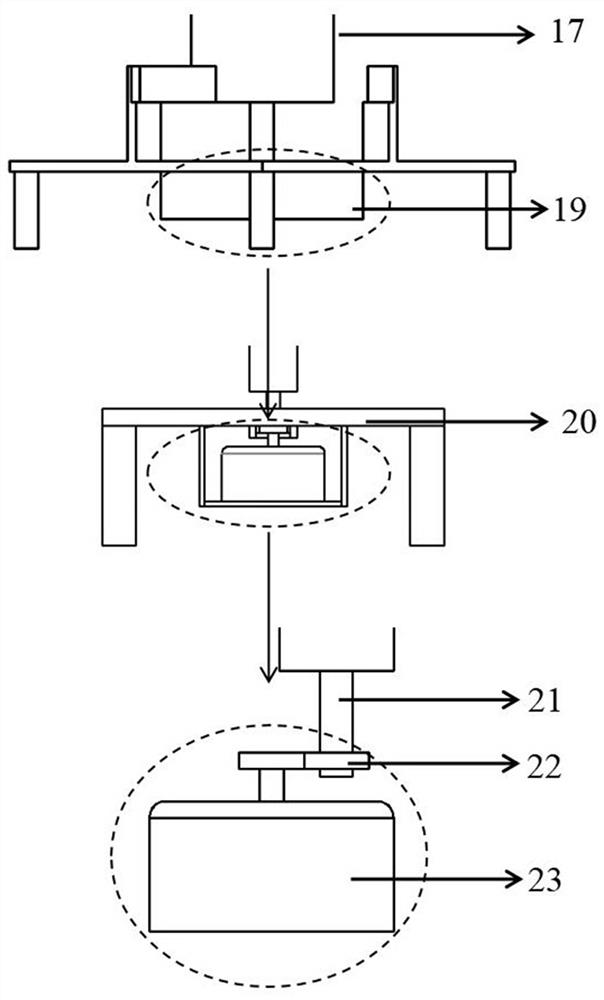

[0040] like figure 2 and 3 As shown, the clamping device B...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com