Universal slide shoveling machine structure

A shovel and row position technology, applied in the field of the universal row position shovel structure, can solve the problems of poor safety and stability of the arc core pulling row position structure, increase the overall size of the mold, etc., to shorten the injection molding cycle, the overall Simple and compact, the effect of reducing the failure rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The invention proposes a universal row position shovel structure.

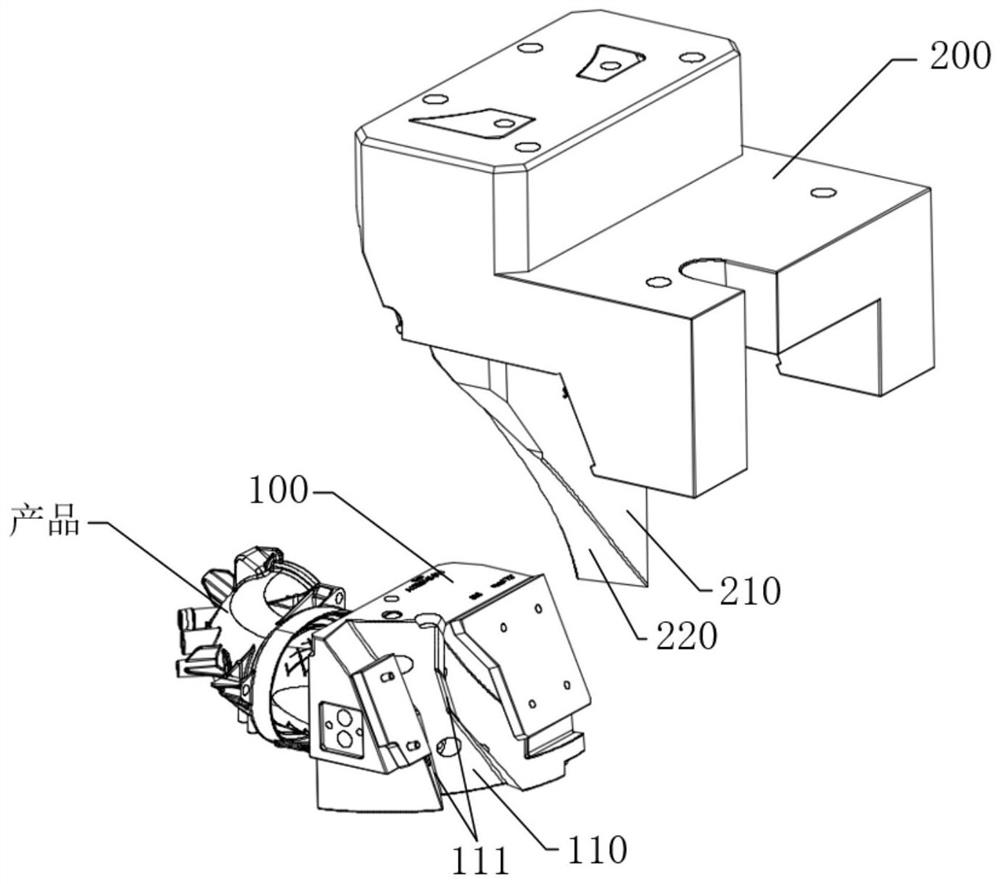

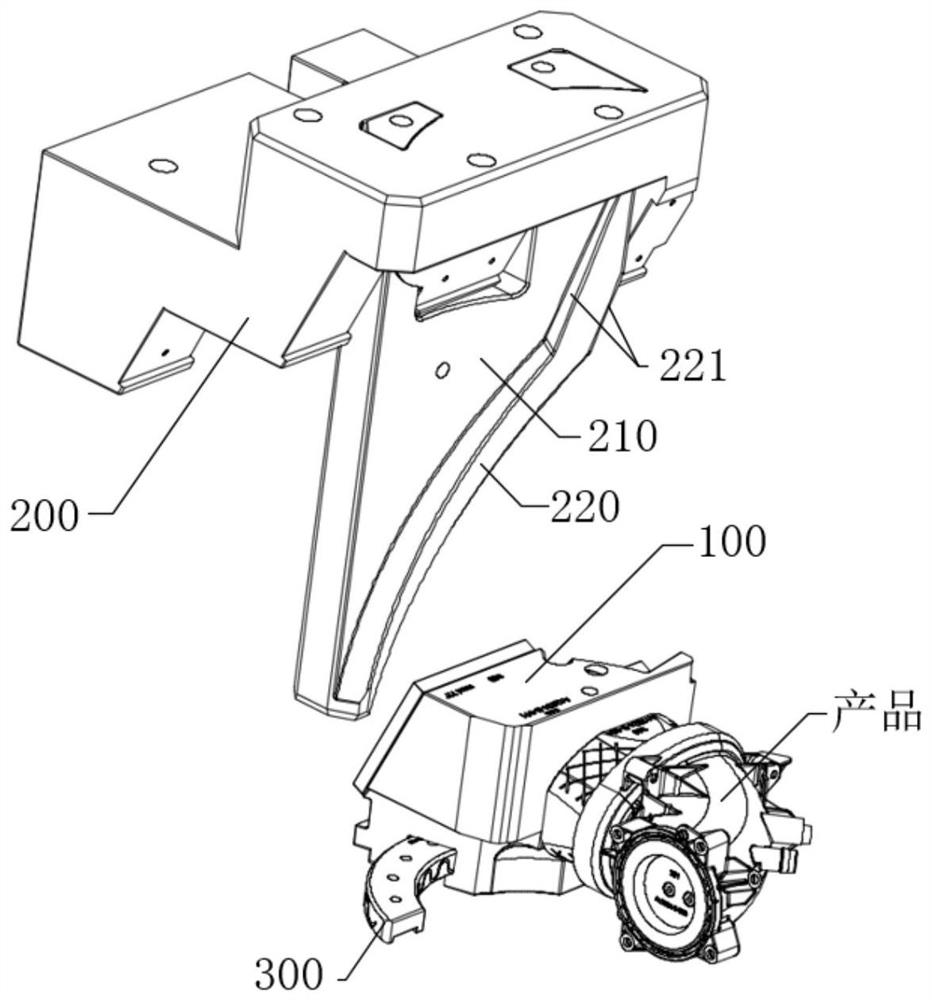

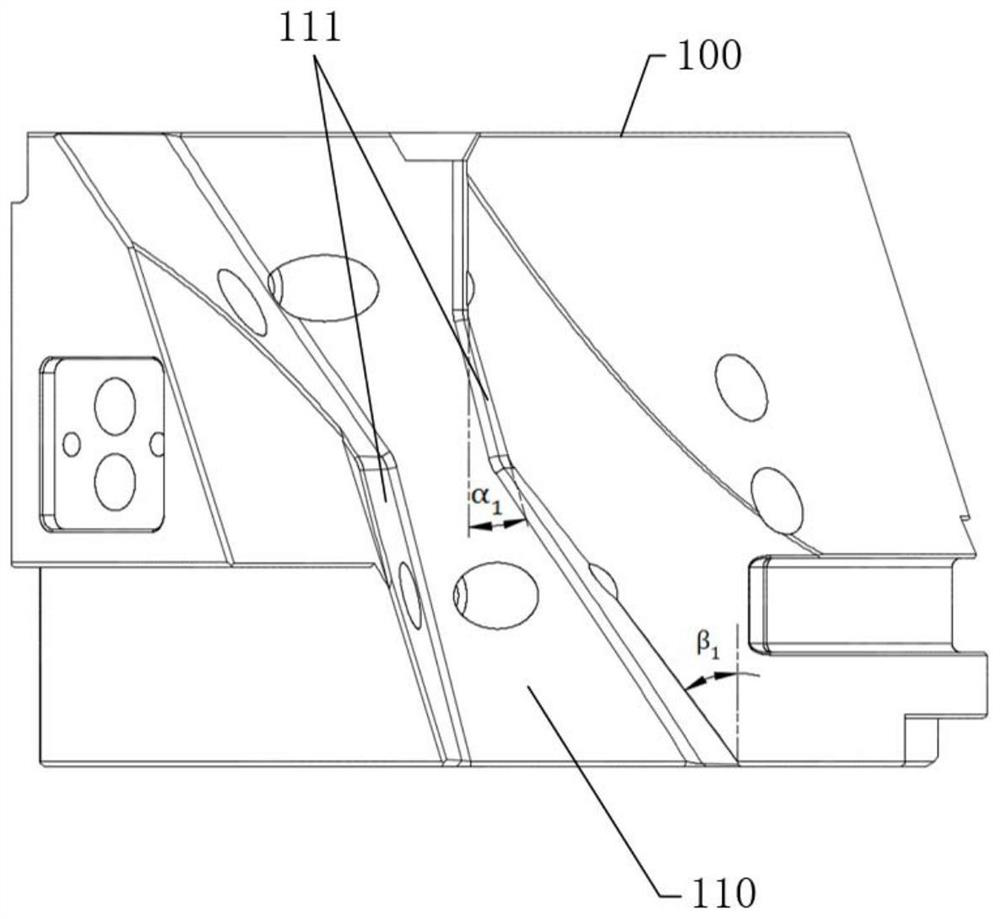

[0015] refer to Figure 1-4 , figure 1 It is a schematic diagram of the back side of the integral explosive structure of an embodiment of the present invention, figure 2 It is a schematic front view of the integral explosive structure of an embodiment of the present invention, image 3 It is a schematic diagram of the back structure of the row seat in an embodiment of the present invention, Figure 4 It is a schematic diagram of the front structure of the slider in an embodiment of the present invention.

[0016] Such as Figure 1-2 As shown, in the embodiment of the present invention, the universal row shovel structure includes: row seat 100 and shovel 200 .

[0017] The fixed mold side of the mold is fixed with an arc guide rail 300, and the row seat 100 is slidably arranged on the arc guide rail 300, and the row seat 100 is provided with a spiral universal slide groove 110. The shovel 200 is f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com