Road shoulder brick

A technology of road shoulder bricks and shoulder bricks, which is applied in the directions of roads, roads, side ditch/curb stones, etc., can solve the problems of weakening the lateral support effect of the road shoulder, affecting the quality of the road surface, poor drainage effect, etc., and achieving good drainage effect and good road surface quality. , The effect of not easy to block

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

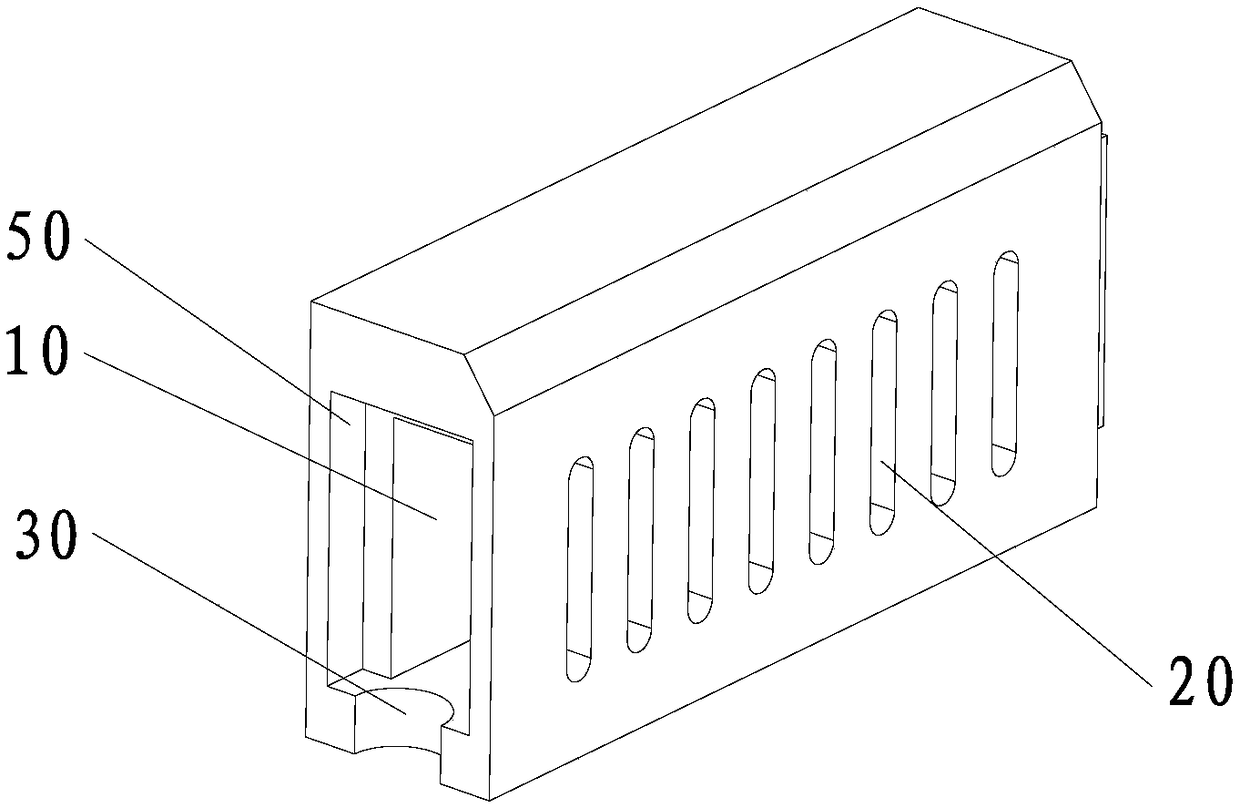

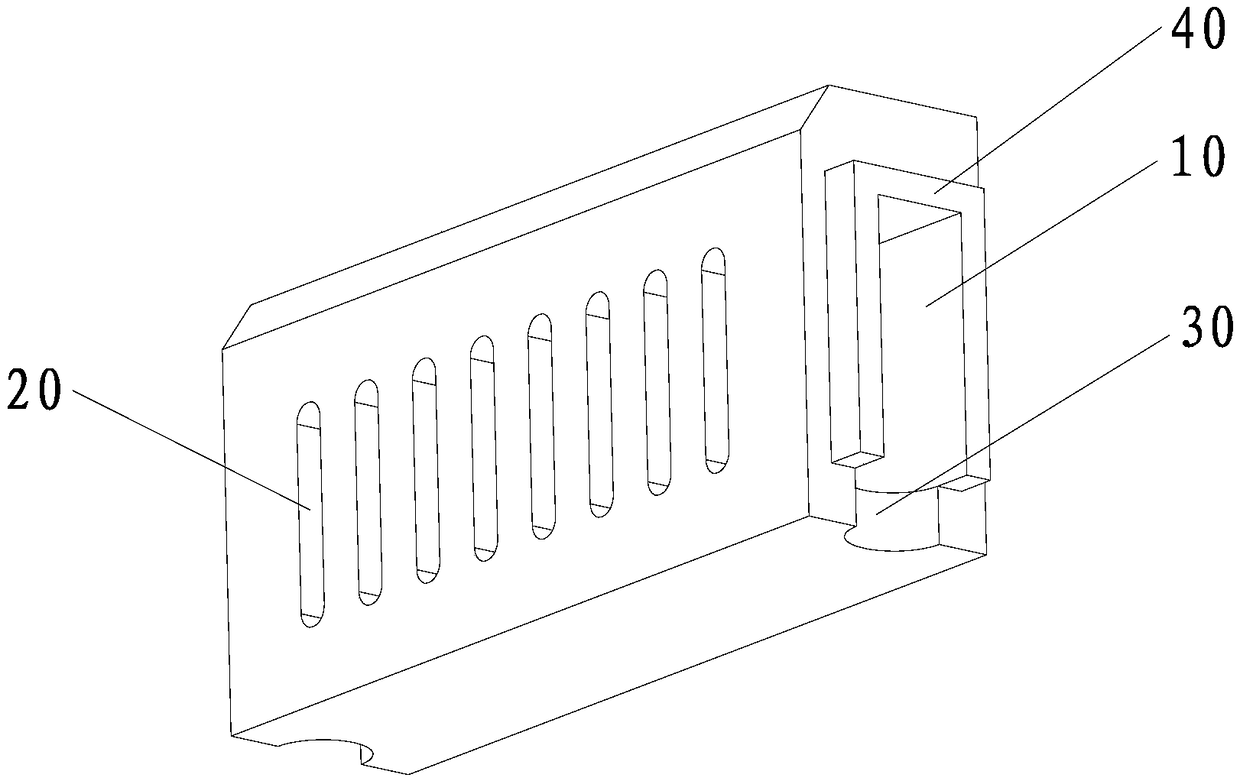

[0035] Such as figure 1 with figure 2 As shown, the road shoulder brick provided in this embodiment includes an integrated brick body, and the brick body is block-shaped as a whole, that is, the upper and lower surfaces of the brick body and the front and rear surfaces are arranged in parallel with each other, and the brick body is laid to form the roadway facing the road surface after the shoulder is laid. The side of one side is flat. The inside of the brick body is provided with a drainage channel 10, that is, the brick body is a hollow brick body, and the end faces of the two ends of the brick body communicate with the outside of the brick body, that is, the end faces of the two ends of the brick body in the length direction have openings. In addition, a plurality of long grooves 20 communicating with the drainage channel 10 are opened on the side facing the roadway after the brick body is laid to form the road shoulder. The floating matter on the water enters the drain...

Embodiment 2

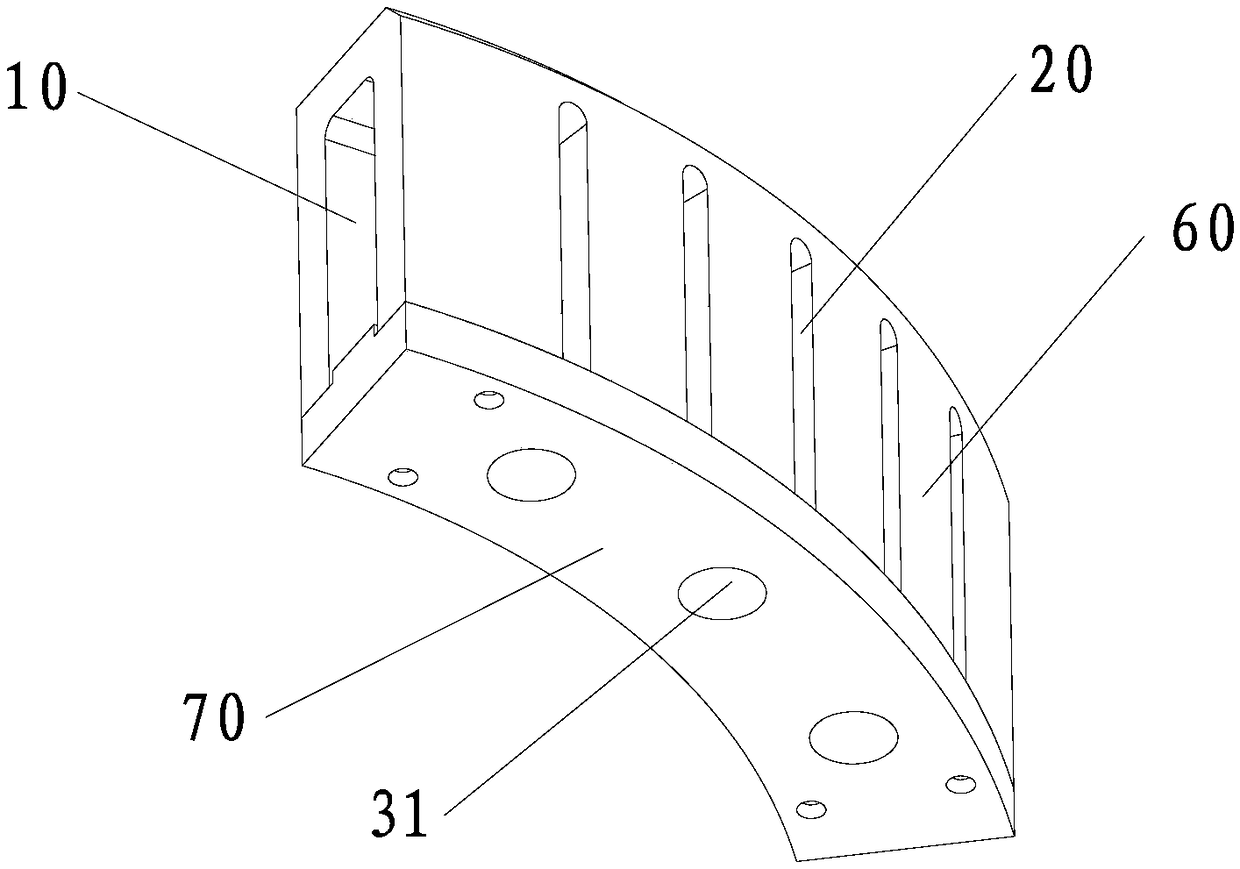

[0038] Such as image 3 , Figure 4 with Figure 5 As shown, the difference between this implementation and Embodiment 1 lies in the following points:

[0039] First of all, in this embodiment, the upper and lower sides of the brick body are fan-shaped, and the side of the side facing the roadway after the brick body is laid to form the road shoulder and the side of the corresponding other side are both curved surfaces, that is, in this embodiment The shoulder bricks provided in the example are suitable for laying the shoulders of intersections or curved road surfaces.

[0040] Secondly, in this embodiment, the brick body is not provided with tenons 40, tenon grooves 50, and semicircular holes 30. The radial direction of the upper or lower side of the fan shape can ensure that the corresponding end faces between two adjacent brick bodies can fit each other when laying the road shoulder, so as to avoid gaps that affect the appearance of the road shoulder. In addition, the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com