Concrete pouring device and operating method for road construction

A technology for concrete and roads, applied in roads, buildings, roads, etc., can solve problems such as extended construction period, inner walls covered with concrete, and untimely cleaning of pouring devices, so as to improve the quality of road surfaces, improve construction efficiency, and achieve good cleaning effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

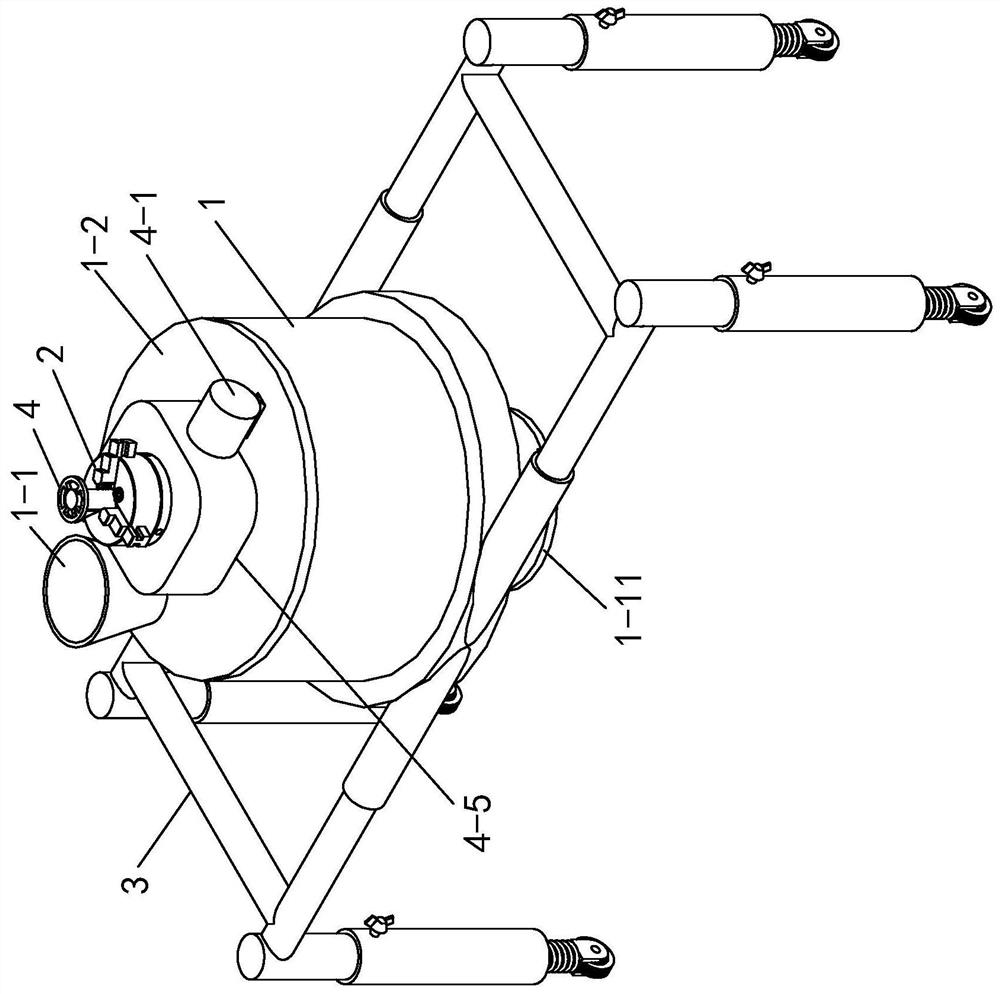

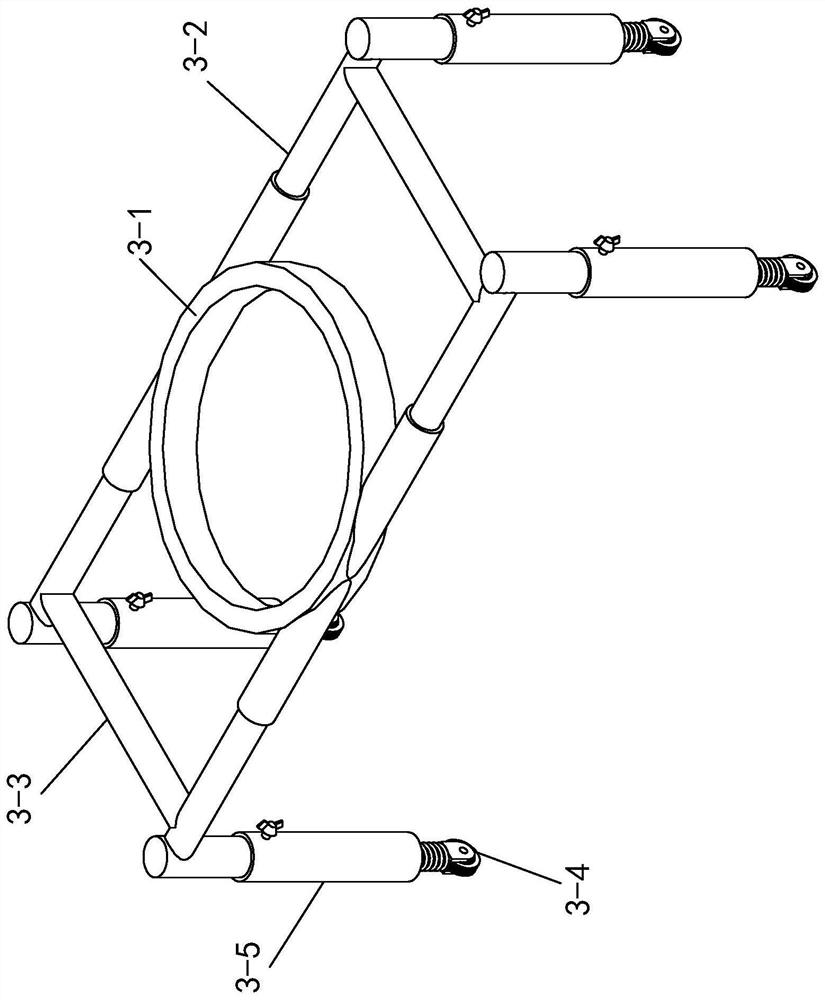

[0026] Specific implementation mode one: as Figure 1 to Figure 7 As shown, the present invention discloses a concrete pouring device for road construction, including a pouring bucket 1, a three-jaw chuck 2, a retractable walking frame 3, a stirring mechanism 4 and a scrubbing mechanism 5;

[0027] The lower end surface of the pouring bucket 1 is provided with a discharge port 1-1, and the discharge port 1-1 is slidably provided with a sealing cover 1-11 (the lower end surface of the discharge port 1-1 is provided with a chute 1-12, the upper end surface of the sealing cover 1-11 is provided with a slider 1-13, the slider 1-13 on the sealing cover 1-11 and the chute 1-12 on the discharge port 1-1 Sliding connection), the sealing cover 1-11 is provided with a handle, the upper end of the pouring bucket 1 is equipped with a bucket cover 1-2, and the bucket cover 1-2 is provided with a feed port 1-21, the The middle part of the bung 1-2 is axially equipped with a stirring mechan...

specific Embodiment approach 2

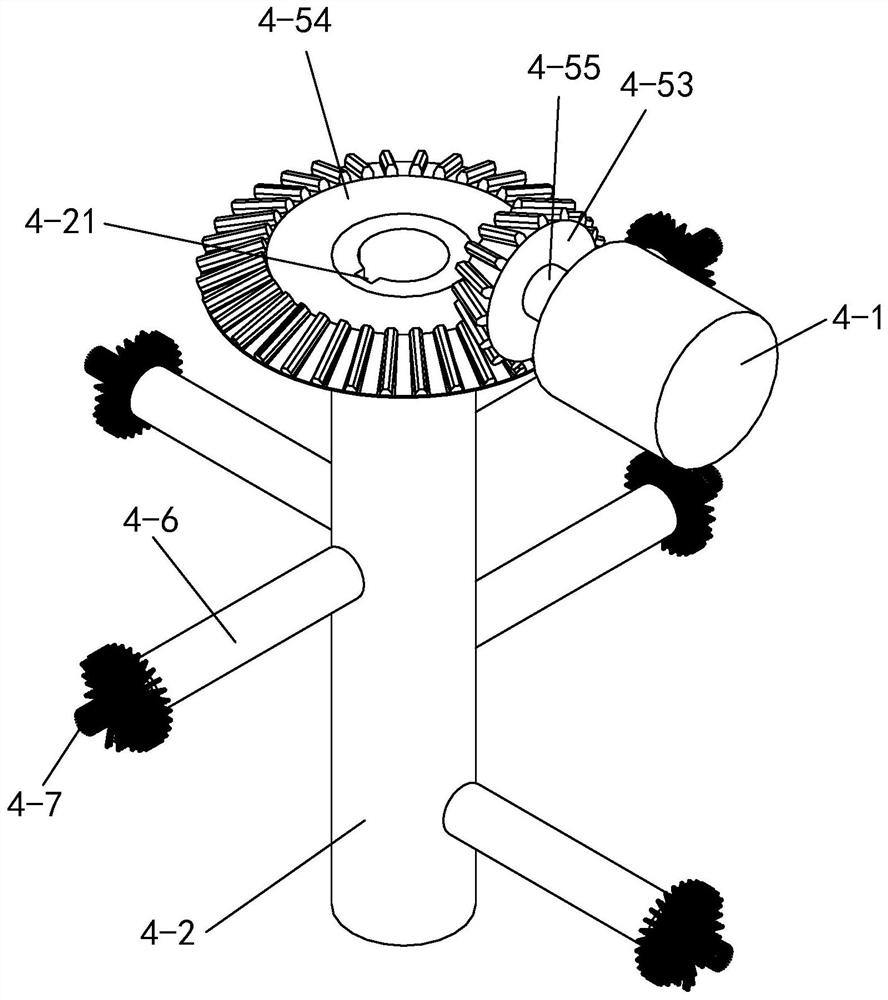

[0028] Specific implementation mode two: as figure 1 , image 3 , Figure 4 , Figure 5 As shown, the stirring mechanism 4 includes a motor 4-1, a shaft tube 4-2, a transition rod 4-3, a shaft sleeve 4-4, a gear box 4-5 and a stirring rod 4-6;

[0029] The disc body of the three-jaw chuck 2 is fixed on the gear box 4-5, and the claws of the three-jaw chuck 2 are used to clamp the outer wall of the bushing 4-4, and the upper end of the bushing 4-4 With a handle 4-41, the inner wall of the shaft sleeve 4-4 is rotationally connected with the upper end of the output shaft 4-51 of the gear box 4-5 through a bearing 4-8, and the output shaft of the gear box 4-5 The lower end of the rod 4-51 is fixedly connected to the upper end of the transition rod 4-3, the output shaft of the motor 4-1 is fixedly connected to the input shaft rod 4-55 of the gear box 4-5, and the shell of the motor 4-1 The body is fixed on the upper end surface of the bucket cover 1-2 through the motor frame, a...

specific Embodiment approach 3

[0030] Specific implementation mode three: as figure 1 , image 3 , Figure 4 As shown, the gearbox 4-5 includes a box body, an output shaft 4-51, a driving bevel gear 4-53, a driven bevel gear 4-54 and an input shaft 4-55;

[0031] The lower end surface of the box body is fixed on the upper end surface of the bucket cover 1-2, the output shaft of the motor 4-1 is fixedly connected with one end of the input shaft rod 4-55, and the motor 4-1 is powered by the outside. The input shaft 4-55 penetrates into the side wall of the box through the rotation of the bearing assembly and is fixedly connected with the middle part of the driving bevel gear 4-53. The bearing assembly includes the second bearing and the bearing seat, and the bearing seat is fixed on the On the inner bottom surface, the driving bevel gear 4-53 meshes with the driven bevel gear 4-54, the driven bevel gear 4-54 is fixed on the outer wall of the shaft tube 4-2, and the shaft tube 4- 2 is rotationally connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com