Friction and extrusion combined energy dissipation damper

A damper and energy dissipation board technology, which is applied to building components, earthquake resistance, building types, etc., can solve the problems of insufficient material yield dispersion area, insufficient energy dissipation structure design, and insufficient initial stiffness of dampers. The effect of reducing seismic response, large initial stiffness, and sufficient energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

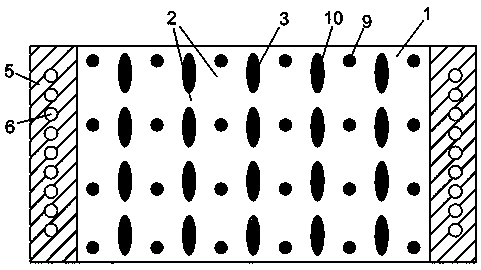

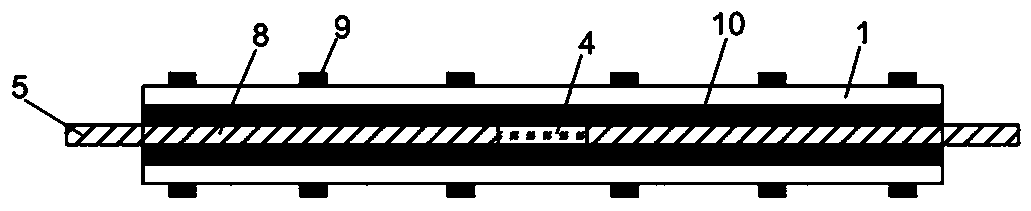

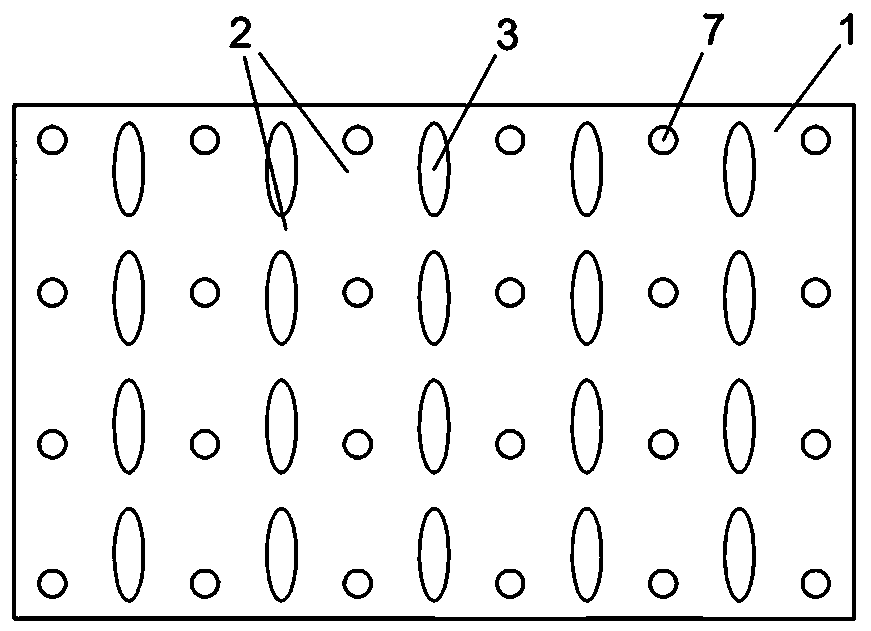

[0021] Example: such as Figure 1~6 As shown, a friction and extrusion combined energy dissipation damper includes energy dissipation steel plates 1, energy dissipation ribs 2, elliptical holes 3 inside, Feng-shaped foamed aluminum energy dissipation plates 4, connecting plates 5, connecting plate screws Hole 6, lead pin hole 7, tension-compression rotation connection energy-dissipating steel plate 8, lead pin 9 and viscoelastic friction energy-dissipating backing plate 10, energy-dissipating steel plate 1 is made of steel plate with low yield point; viscoelastic friction energy-dissipating backing plate 10 Made of high damping rubber;

[0022] A friction and extrusion combined energy dissipation damper is provided with a Feng-shaped foamed aluminum energy-dissipating plate 4 in the middle, and the Feng-shaped foamed aluminum energy-dissipating plate 4 is made of foamed aluminum. On the left and right sides of the energy dissipation plate 4, four energy-dissipating steel plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com