Lead dot squeezing type visco-elasticity friction damper

A friction damper and viscoelastic technology, applied in the field of vibration control of building structures, can solve problems such as insufficient material yield dispersion area, insufficient energy-dissipating structure design, and insufficient initial stiffness of the damper, etc., to reduce earthquake response, Ease of replacement and sufficient energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to further illustrate the present invention, the present invention will be described in detail below in conjunction with the accompanying drawings and embodiments, but they should not be construed as limiting the protection scope of the present invention.

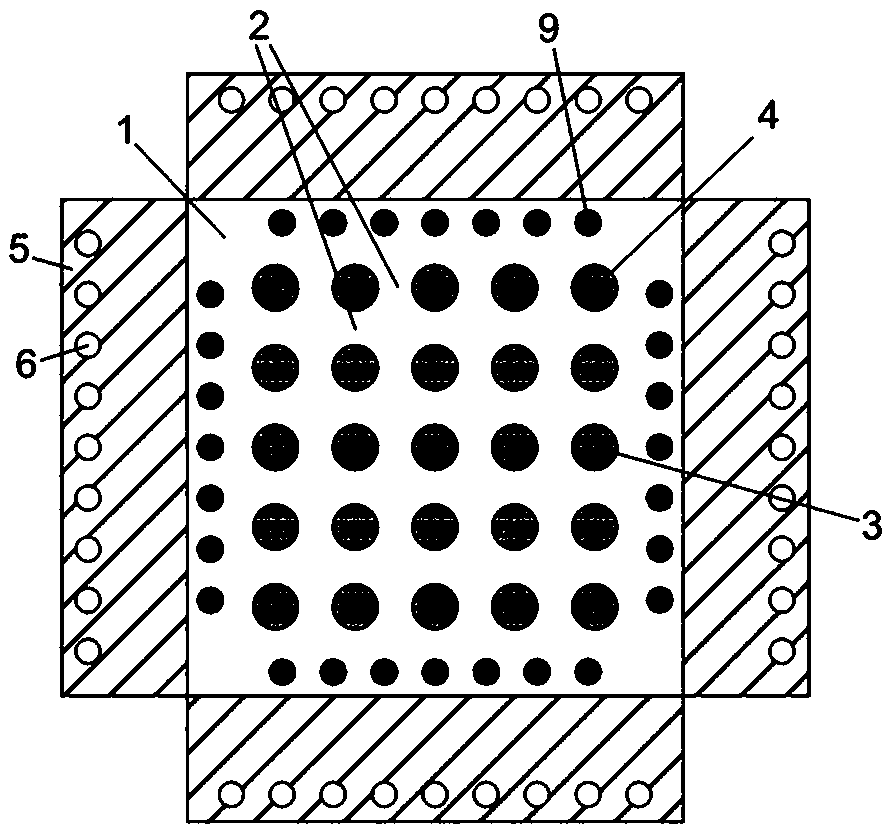

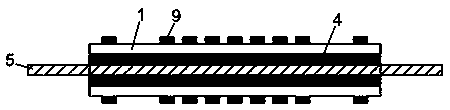

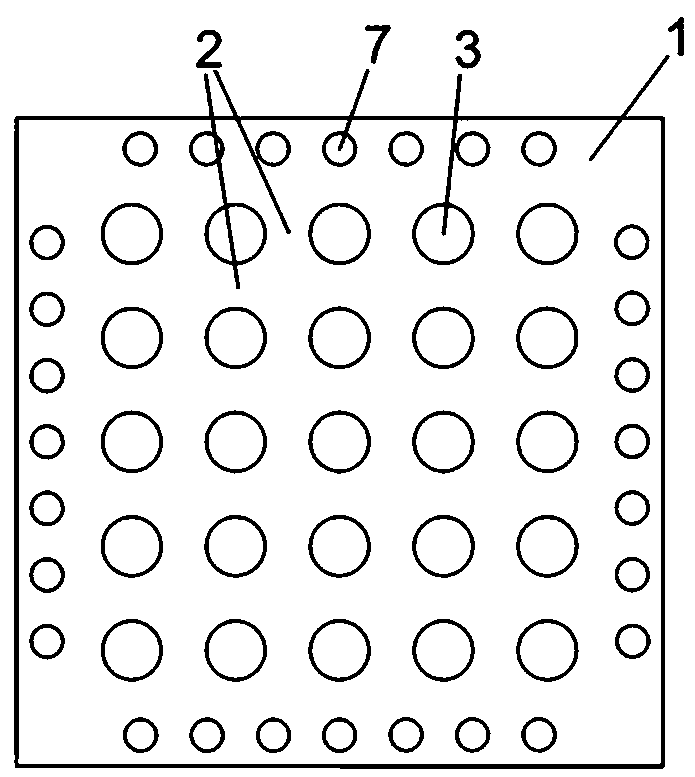

[0023] Example: such as Figure 1~6 As shown, a lead pin extruded viscoelastic friction damper includes an energy-dissipating steel plate 1, an energy-dissipating rib 2, a round hole 3 inside, a viscoelastic friction energy-dissipating backing plate 4, a connecting plate 5, and connecting plate screw holes 6. Lead pin hole 7, extruded and connected energy-dissipating steel plate 8, lead pin 9 and built-in foamed aluminum extruded energy-dissipating plate 10, energy-dissipating steel plate 1 is made of steel plate with low yield point; the viscoelastic friction loss The backing plate 4 is made of high damping rubber. The extruded connection energy-dissipating steel plate 8 is made of steel plate with low yie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com