Plunger hydraulic cylinder with oil being fed through middle position

A hydraulic cylinder and oil feeding technology, which is applied in the field of plunger hydraulic cylinders, can solve the problems affecting the use of single-acting plunger hydraulic cylinders, affecting the installation of single-acting plunger hydraulic cylinders, etc., so as to eliminate the phenomenon of slowing down or stagnation, and movement Uniform and smooth effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

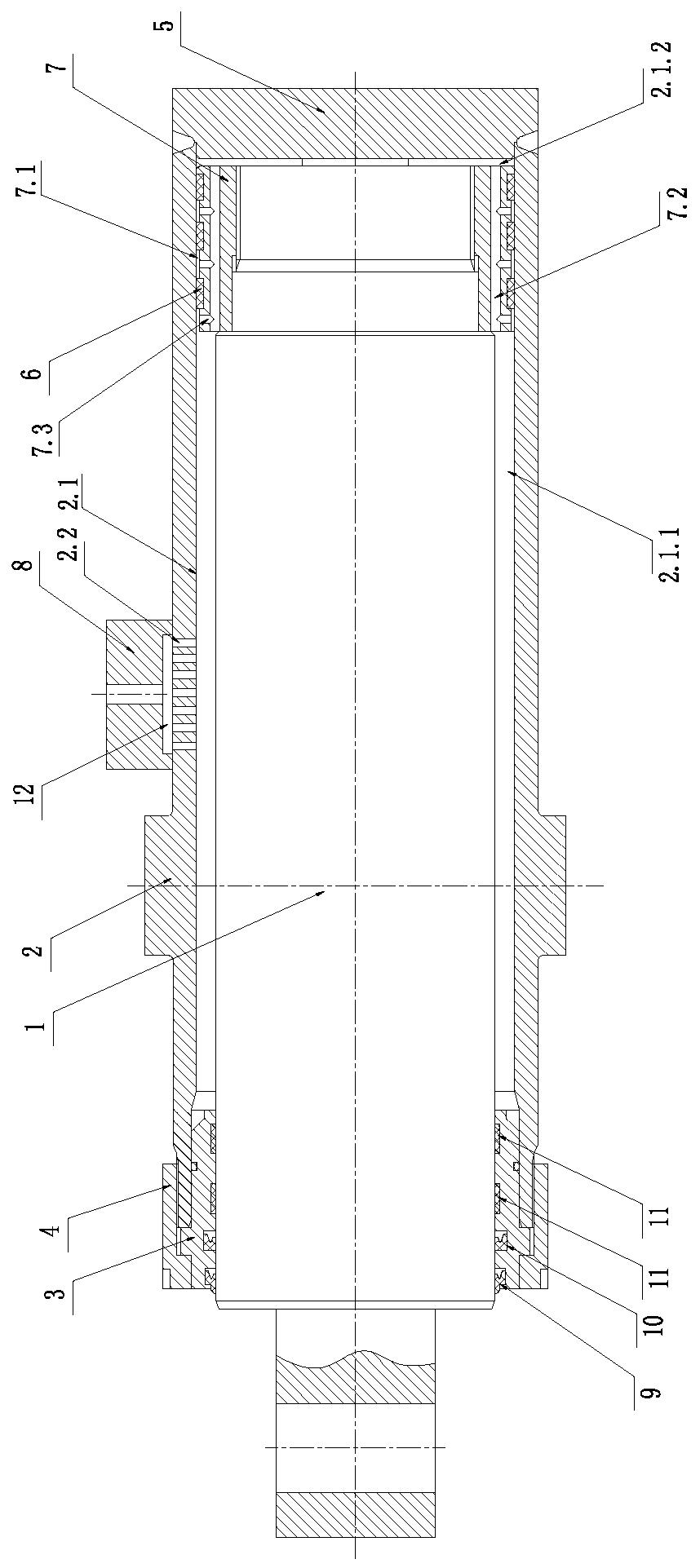

[0008] Such as figure 1 As shown, a plunger hydraulic cylinder with oil inlet in the middle is characterized in that it includes a plug rod 1, a cylinder body 2, a guide sleeve 3, a cylinder head 4, a cylinder bottom 5, a support ring 6, a piston 7, and an oil inlet joint 8. Dustproof ring 9, shaft sealing ring 10 and support ring 11, a cavity 2.1 is arranged in the cylinder body, the cylinder bottom 5 is fixedly arranged at the rear end of the cylinder body 2, the guide sleeve 3 is arranged at the front end of the cylinder body 2, and the cylinder head 4 Set on the guide sleeve 3 and the cylinder body 2, the piston 7 is set in the cavity 2.1 in the cylinder body 2, the piston 7 divides the cavity 2.1 into a rod cavity 2.1.1 and a rodless cavity 2.1.2,

[0009] A plurality of annular grooves 7.1 are arranged on the piston 7, and a support ring 6 is set between two adjacent annular grooves 7.1; a plurality of axial through holes 7.2 are evenly arranged in the axial direction of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com