Seat headrest assembly and vehicle

A headrest and assembly technology, applied in the field of seat headrest assembly, can solve the problems of increased assembly man-hours, large use restrictions, and high cost, and achieve the effect of improving comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

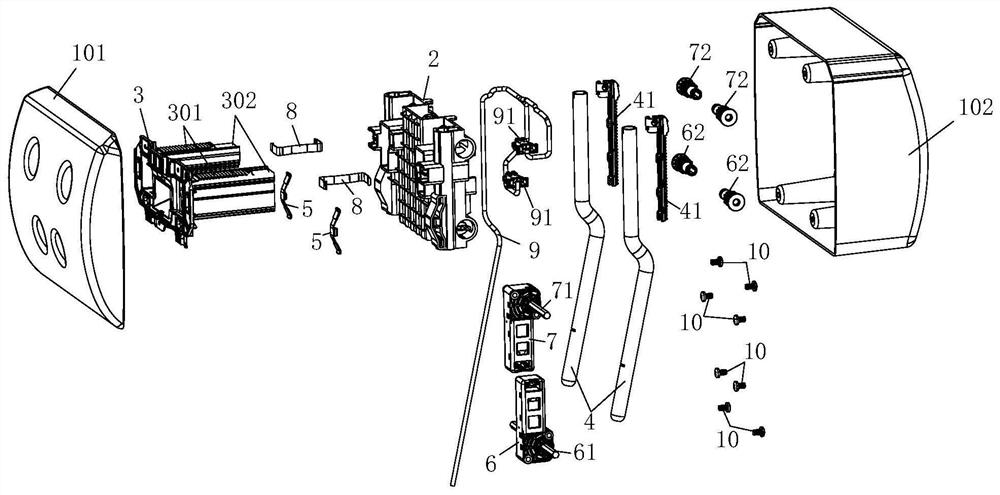

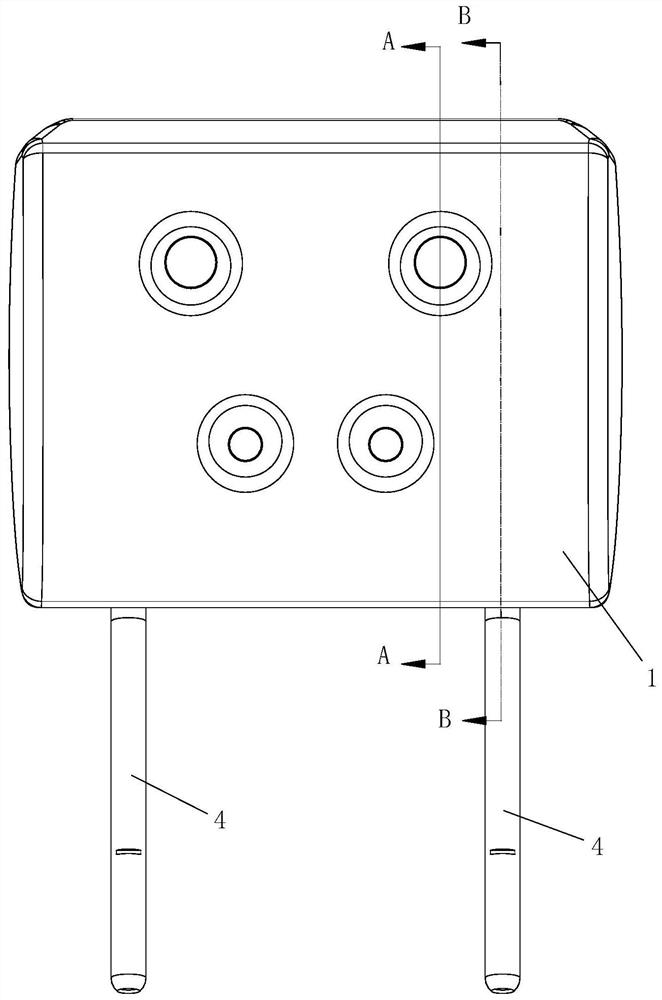

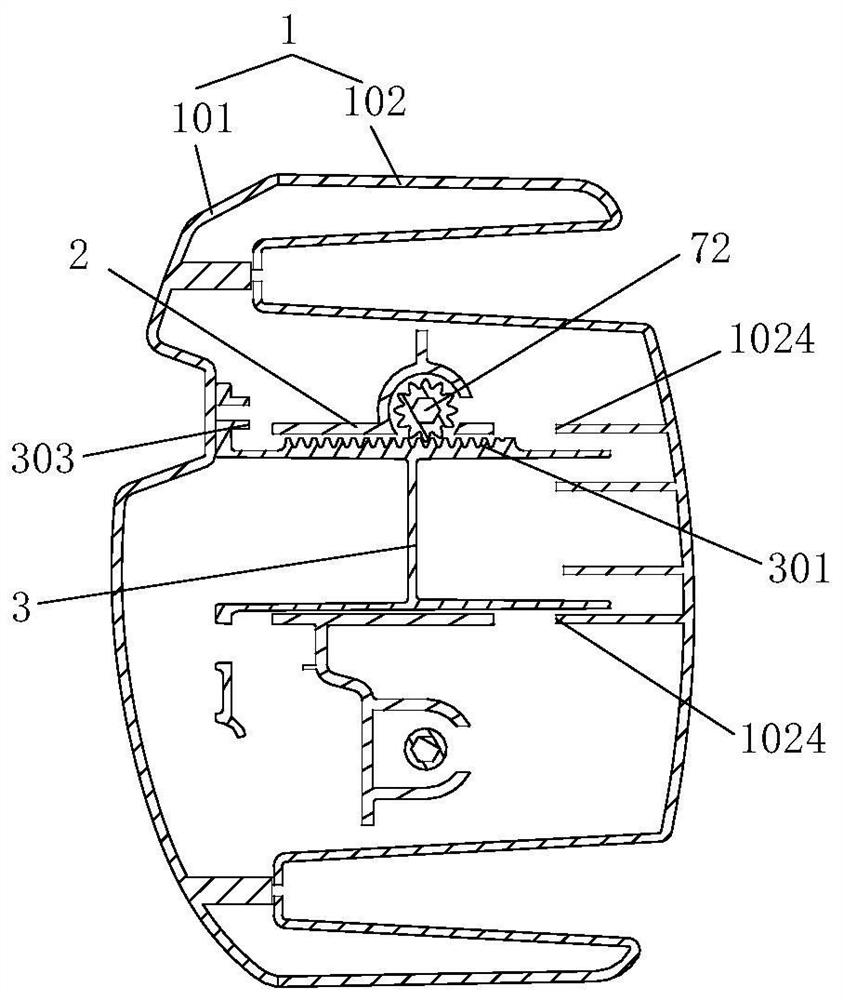

[0052] This embodiment relates to a seat headrest assembly. In terms of overall composition, the seat headrest assembly includes a headrest rod 4 , an intermediate bracket 2 , a sliding bracket 3 and a housing 1 .

[0053] Wherein, one end of the headrest rod 4 can be slidably arranged in the middle bracket 2 up and down, and the sliding bracket 3 can be slidably arranged in the middle bracket 2 back and forth. , and the front and rear driving parts connected with the sliding bracket 3 transmissions, the up and down driving parts are used to drive the middle bracket 2 to slide up and down along the headrest rod 4, and the front and rear driving parts are used to drive the sliding bracket 3 to slide back and forth relative to the middle bracket 2. In addition, the housing 1 is fixedly connected with the sliding bracket 3 , the intermediate bracket 2 and the sliding bracket 3 are accommodated in the housing 1 , and the other end of the headrest rod 4 protrudes out of the housing ...

Embodiment 2

[0085] This embodiment relates to a vehicle, and the seat of the vehicle is provided with the seat headrest assembly described in the first embodiment. Meanwhile, as a further preferred implementation form, the vehicle of this embodiment is further provided with a collision detection unit and a control unit. Among them, the collision detection unit is used to obtain the collision signal of the vehicle, and send the collision signal to the control unit, and the control unit is used to control the front and rear driving parts to make the seat headrest assembly close to the driver's head.

[0086] It should be noted that the collision detection unit in this embodiment may specifically use a radar, or other sensing components capable of checking an impending collision of a vehicle. However, the control unit in this embodiment can be an electronic control unit in a vehicle, that is, an ECU (Electronic Control Unit). The vehicle of this embodiment adopts the seat headrest assembly ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com