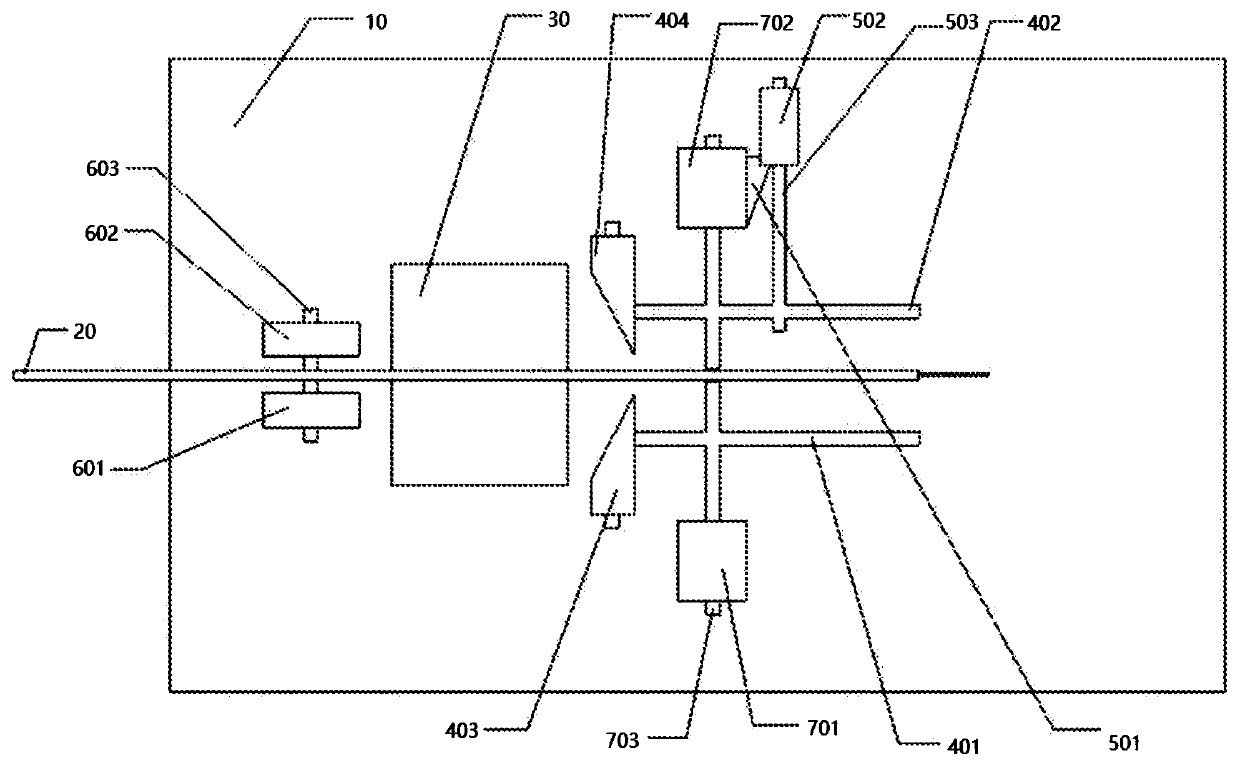

A kind of optical fiber production equipment based on 5g communication

A production equipment and optical fiber technology, applied in the field of optical fiber production equipment, can solve the problems of cutting edge shaking and offset, low production efficiency, difficulty in ensuring transmission rate, etc., to increase cutting quality, improve production efficiency, and quickly and effectively fix Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

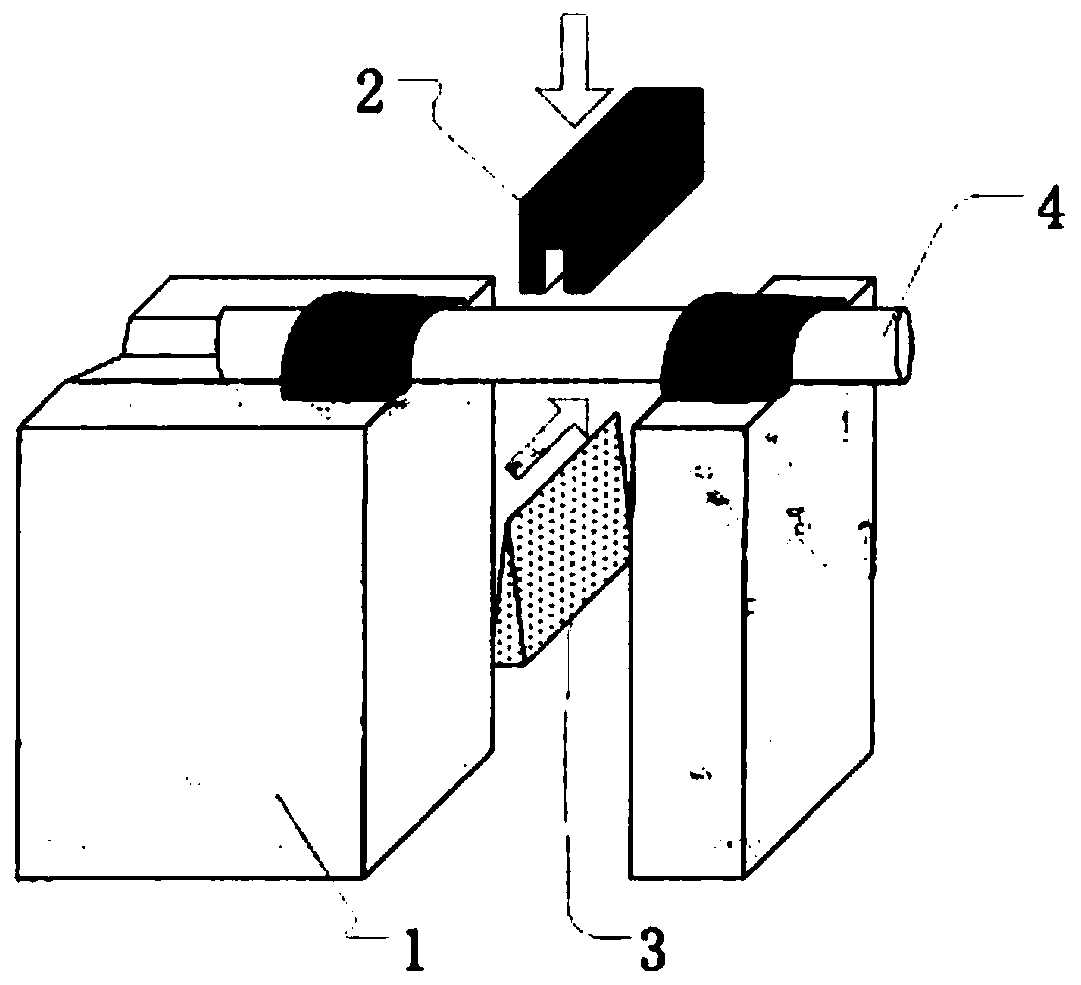

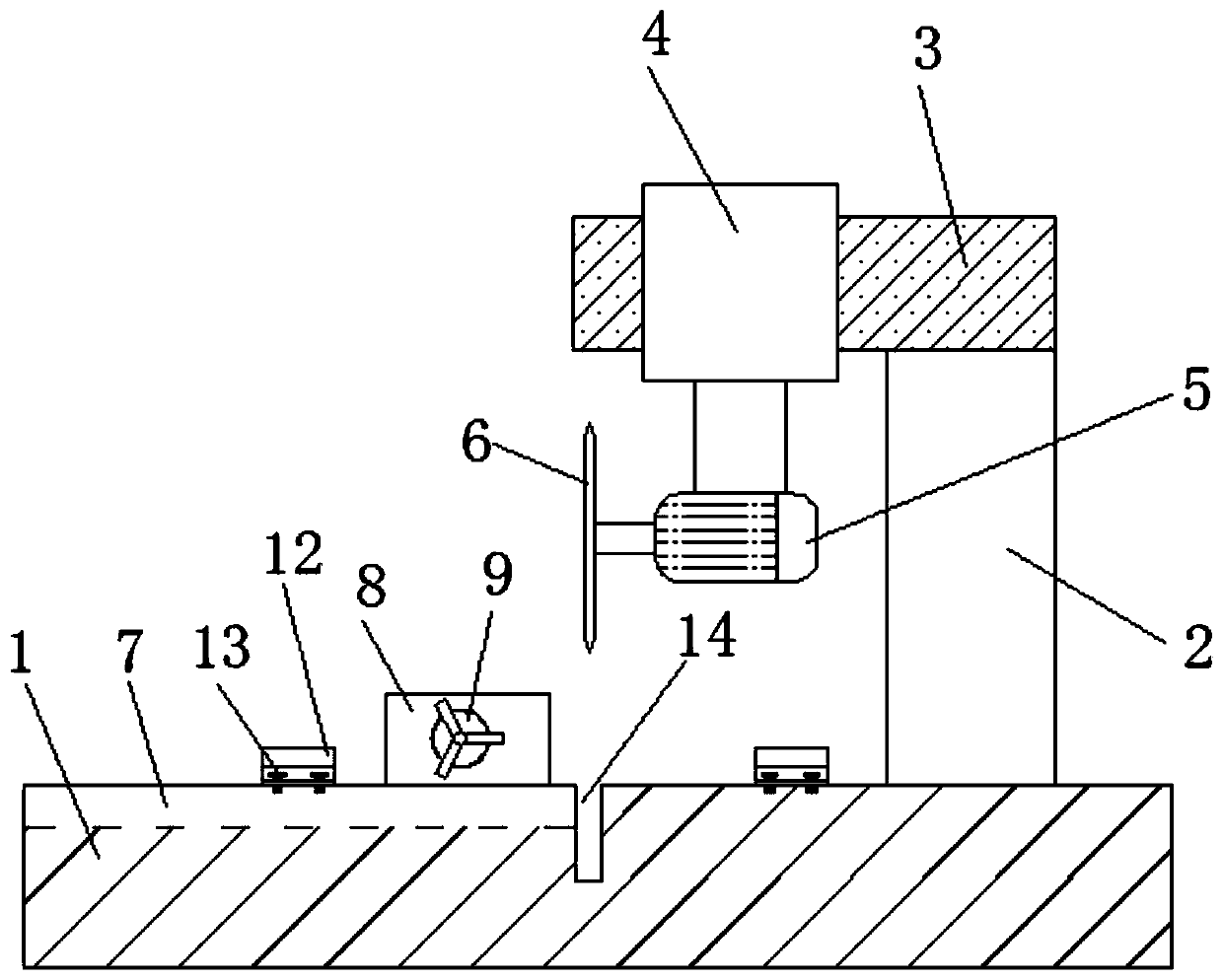

Embodiment 1

[0042] see Figure 3-5, a kind of optical fiber production equipment based on 5G communication, comprising a base 1, the upper end of the base 1 is provided with a pillar 2, the end of the pillar 2 is provided with a bearing rod 3, and a hydraulic cylinder is installed on the side of the bearing rod 3 4. The telescopic end of the hydraulic cylinder 4 is equipped with a motor 5, the output end of the motor 5 is rotated and installed with a cutting knife 6, the upper end of the base 1 is provided with a guide groove 7, and the upper end of the base 1 is provided with a fixed Block 8, the inside of the fixed block 8 is provided with a threaded rod 9, the inner end of the threaded rod 9 is connected with a clamping plate 11 through a rotating bearing 10, the upper end of the base 1 is provided with a hoop 12, the hoop The ring 12 is fixed on the upper end of the base 1 by bolts 13 , and the inside of the base 1 is provided with a cutter groove 14 .

[0043] The pillars 2 are prov...

Embodiment 2

[0057] An optical fiber production equipment based on 5G communication, comprising a base 1, a support 2 is provided at the upper end of the base 1, a supporting rod 3 is provided at the end of the supporting rod 3, and a hydraulic cylinder 4 is installed on the side of the supporting rod 3 , the telescopic end of the hydraulic cylinder 4 is equipped with a motor 5, the output end of the motor 5 is rotated and installed with a cutting knife 6, the upper end of the base 1 is provided with a guide groove 7, and the upper end of the base 1 is provided with a fixed block 8. The inside of the fixed block 8 is provided with a threaded rod 9, the inner end of the threaded rod 9 is connected with a clamping plate 11 through a rotating bearing 10, and the upper end of the base 1 is provided with a hoop 12, and the hoop 12 is fixed on the upper end of the base 1 by bolts 13, and the inside of the base 1 is provided with a cutter groove 14.

[0058] The pillars 2 are provided with two gr...

Embodiment 3

[0066] An optical fiber production equipment based on 5G communication, comprising a base 1, a support 2 is provided at the upper end of the base 1, a supporting rod 3 is provided at the end of the supporting rod 3, and a hydraulic cylinder 4 is installed on the side of the supporting rod 3 , the telescopic end of the hydraulic cylinder 4 is equipped with a motor 5, the output end of the motor 5 is rotated and installed with a cutting knife 6, the upper end of the base 1 is provided with a guide groove 7, and the upper end of the base 1 is provided with a fixed block 8. The inside of the fixed block 8 is provided with a threaded rod 9, the inner end of the threaded rod 9 is connected with a clamping plate 11 through a rotating bearing 10, and the upper end of the base 1 is provided with a hoop 12, and the hoop 12 is fixed on the upper end of the base 1 by bolts 13, and the inside of the base 1 is provided with a cutter groove 14.

[0067] The pillars 2 are provided with two gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com