Machining method for spring embracing part

A processing method and station technology, applied in the field of circular parts processing, can solve the problems of inability to change the length, the difficulty of the mold, and the complex rounding method, and achieve the effect of improving the processing accuracy, correct position correspondence, and ensuring accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

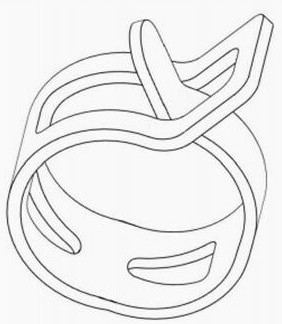

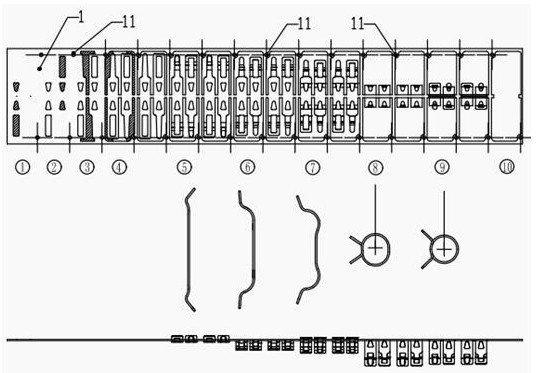

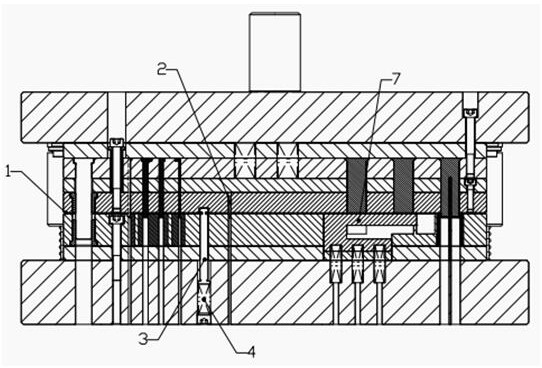

[0024] The processing method of the spring hug provided by this embodiment has an assembly hole and two weight-reducing holes (such as figure 1As shown), one end of the spring bag passes through the assembly hole to form a circular bag, which is characterized in that it includes the following steps: S1, cutting the material, drawing the spring with CAD according to the expanded length and shape of the spring bag to be prepared The layout of the hugging processing (such as figure 2 shown), and then cut the metal coil into metal strip 1 according to the width of the layout diagram drawn, the metal strip 1 after cutting is rectangular, and the width is greater than the length after the spring is expanded; each in the layout diagram There are two circular wrappers corresponding to the station, and the width of each processing station is greater than the expansion width of the two spring wrappers; S2, put the metal strip material 1 into the automatic feeder, and the metal strip ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com