A Distributed PCA-Based Multi-Condition Fault Monitoring Method

A fault monitoring, multi-working-condition technology, applied in electrical testing/monitoring, testing/monitoring control systems, instruments, etc., can solve problems such as failure to monitor the model and get the desired effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

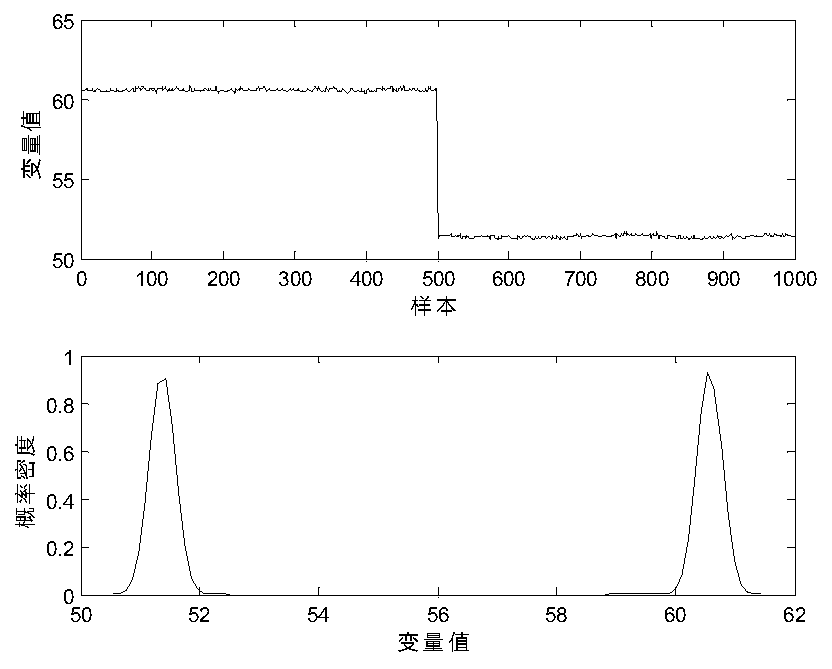

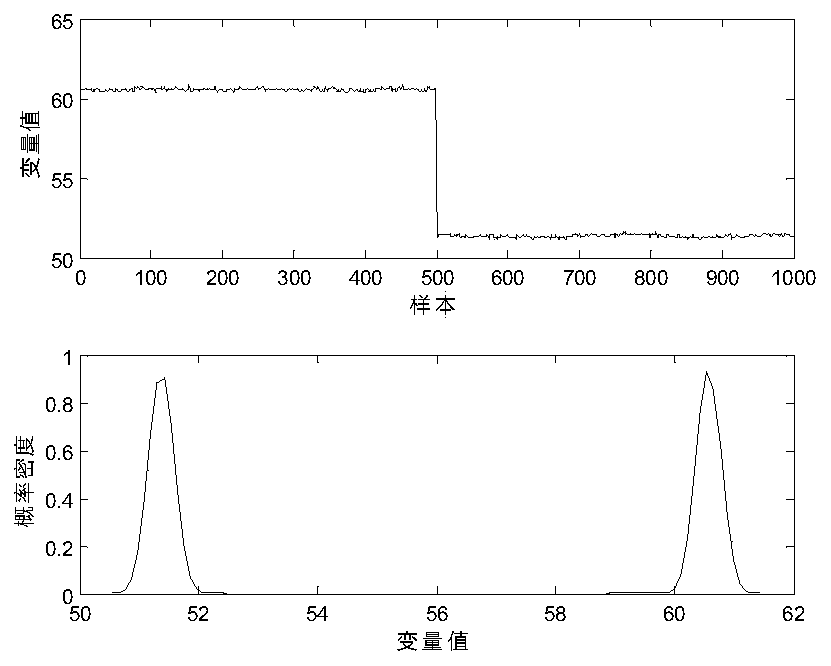

[0073] This embodiment provides a multi-working-condition fault monitoring method based on distributed PCA. This embodiment takes a common chemical process—TE process (Tennessee Eastman Process) as an example; the experimental data comes from the TE process, and the TE process 21 faults were monitored; see Figure 4 , the method includes:

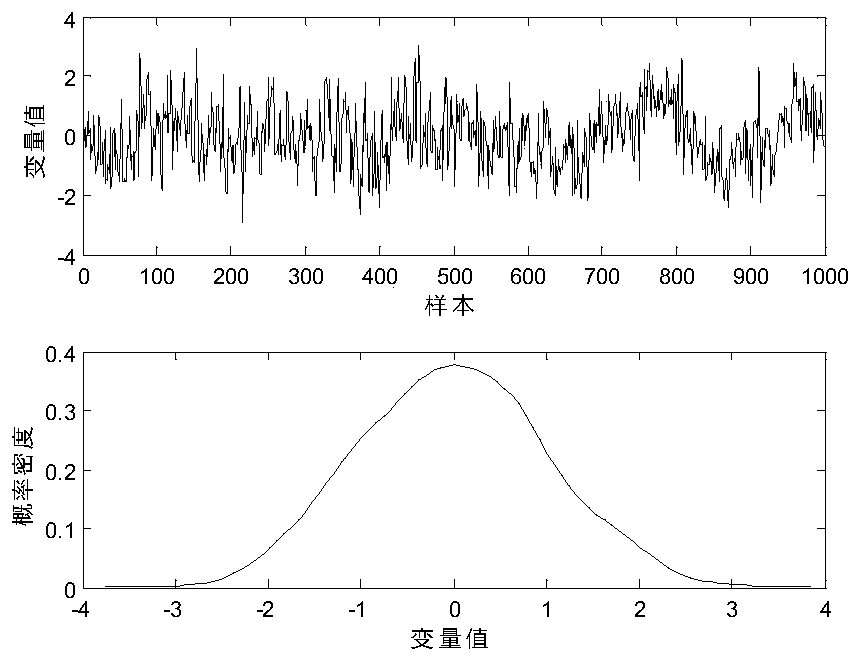

[0074] Step 1: Obtain the normal working condition data set, and standardize it to obtain the data set through the LNS method. The LNS method is:

[0075] Assuming that the m-dimensional original process data is , the LNS method uses the local neighborhood mean and standard deviation information of each sample to standardize, so as to normalize each working condition and obtain standardized data with a single distribution. The standardized data is:

[0076]

[0077] in, represents the sample x i Among the a nearest neighbors in X, the distance criterion is determined by the Euclidean distance; represents the sample x i the first ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com