A real-time quantifiable evaluation method for truss manufacturing quality

A technology for manufacturing quality and trusses, applied in data processing applications, instruments, geometric CAD, etc., can solve the problems of not being able to obtain quantitative results of manufacturing quality, not being able to realize real-time evaluation, and subjective factors being greatly affected, so that the evaluation results can be quantified, The evaluation result is intuitive and the effect of reducing the influence of human intervention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

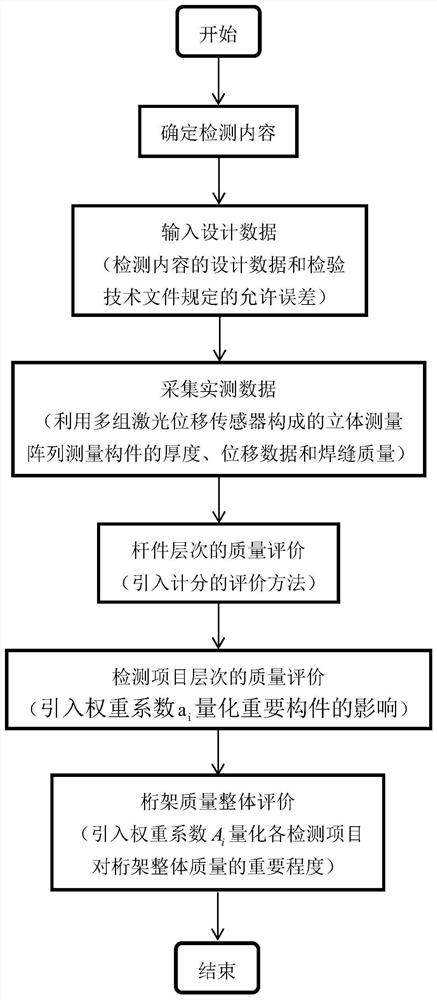

[0046] like figure 1 As shown, the real-time quantifiable evaluation method of truss manufacturing quality specifically includes the following steps:

[0047] 1. Determine the test content: determine the specific test content according to the test technical documents; consult the test technical documents to obtain the specified allowable error; consult the design documents to determine the design requirements for each test content. The testing items are the thickness of the truss structure chord (web), the plane size of the truss structure chord (web), the deformation of the truss structure nodes, and the size of the truss structure weld; Nodes shall be determined according to the inspection technical documents;

[0048] 2. Input design data: input the design data of the content to be tested and the allowable error stipulated in the inspection technical documents and specifications;

[0049] 3. Acquisition of measured data: Use a stereoscopic measurement array composed of mu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com