Small rotary type sand screening device

A rotary sieve, small-scale technology, applied in the direction of filtration, solid separation, chemical instruments and methods, etc., can solve the problems of insufficient sand sieving, inconvenient dumping of stones, etc., and achieve the effect of realizing automatic production, reducing manpower and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

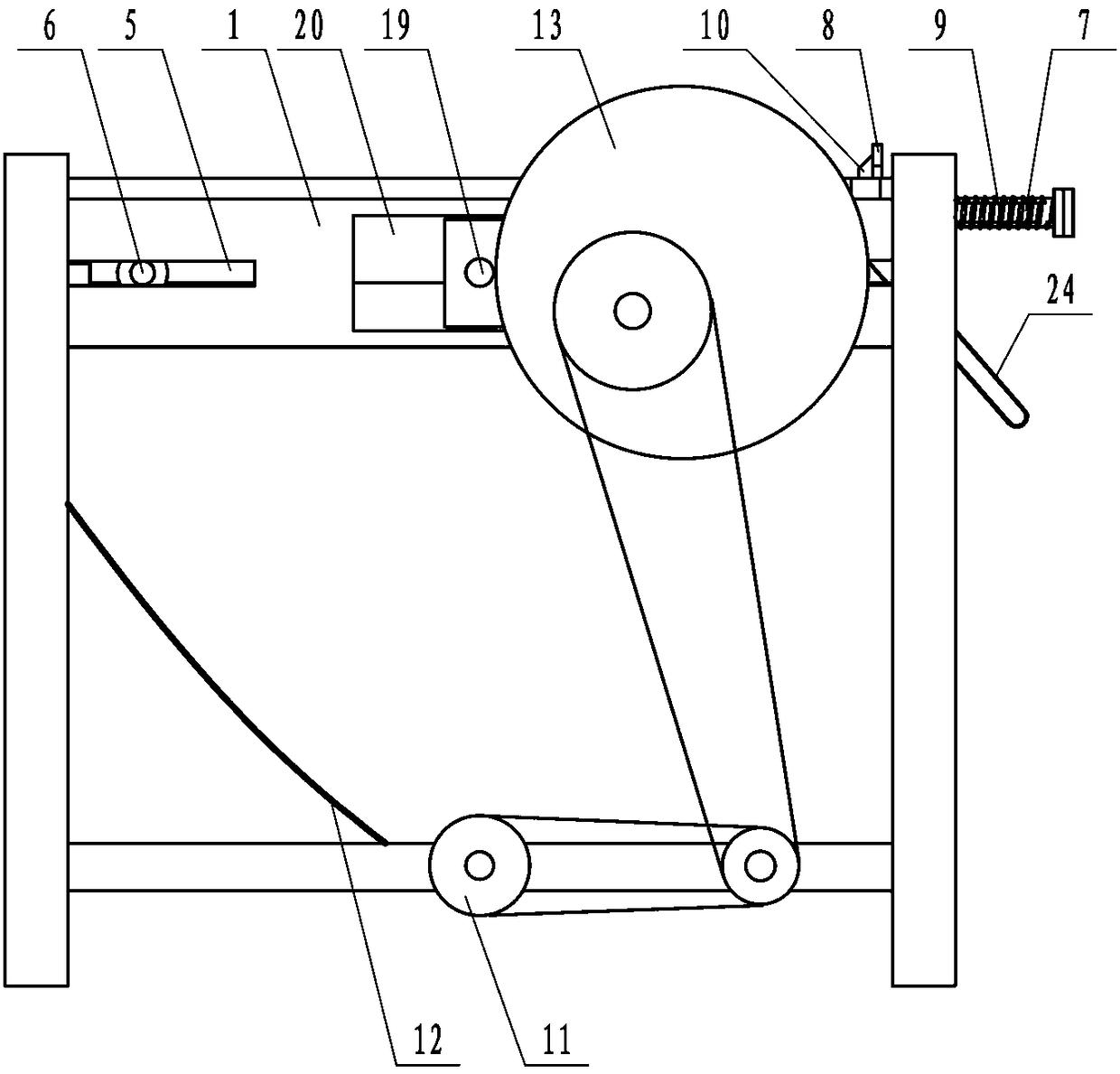

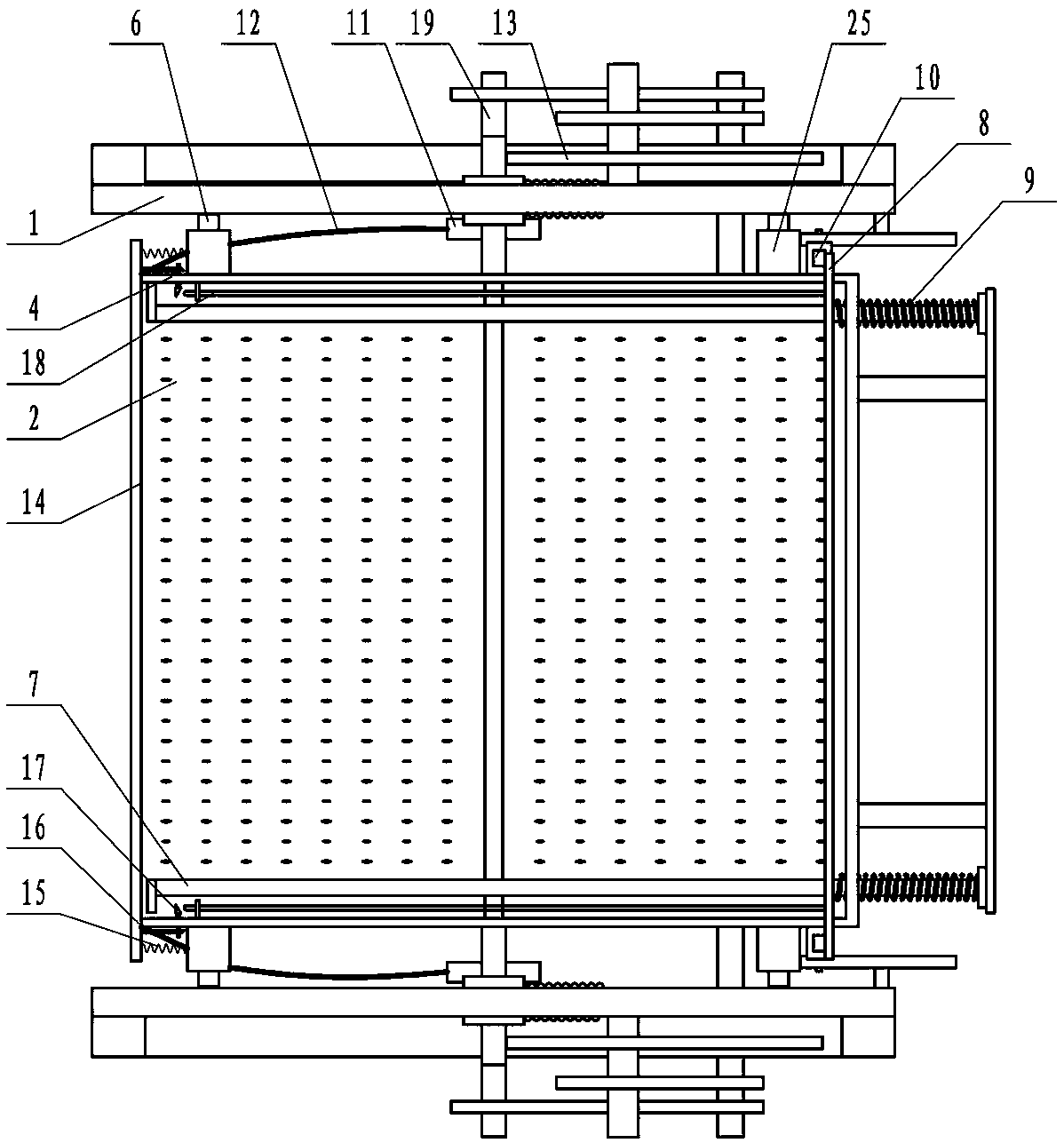

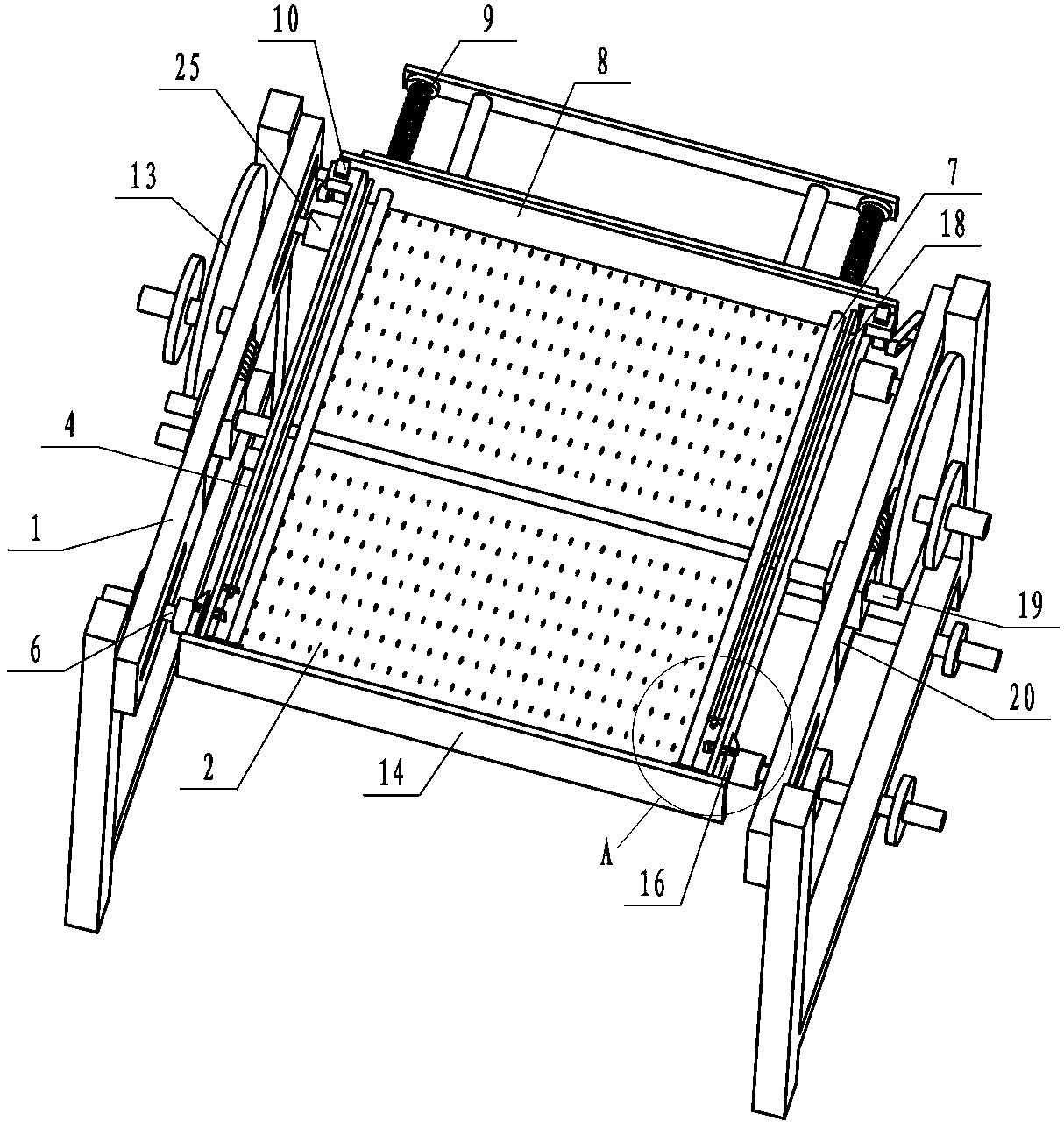

[0016] The specific implementation manners of the present invention will be described in further detail below in conjunction with the accompanying drawings.

[0017] Depend on Figure 1 to Figure 8 Provide, the present invention comprises two vertical boards 1 that are placed in parallel front and rear, and there is a screen cloth 2 that can move left and right along the vertical board 1 and rotate between the two vertical boards 1; the screen cloth 2 can return to a horizontal position after rotation, and the screen cloth The mesh size of 2 is adjustable; a vertical baffle plate 4 is fixed on the front and rear sides of the screen 2, and the inner sides of the two vertical plates 1 are provided with grooves 5 corresponding to each other and arranged horizontally. There is a positioning rod 6 corresponding to the groove 5 on the outer surface of the baffle plate 4 on the same side. When the screen cloth 2 is horizontal, the outer end of the positioning rod 6 can slide left and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com