Industrial pressure vessel convenient to move

A pressure vessel and industrial technology, applied in the field of industrial pressure vessels that are easy to move, can solve the problems of lack of anti-skid protection at the base fixed place, reducing the use effect of the pressure vessel, and difficult to move freely, so as to improve the placement stability and enhance the flexibility of use. , the effect of convenient movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

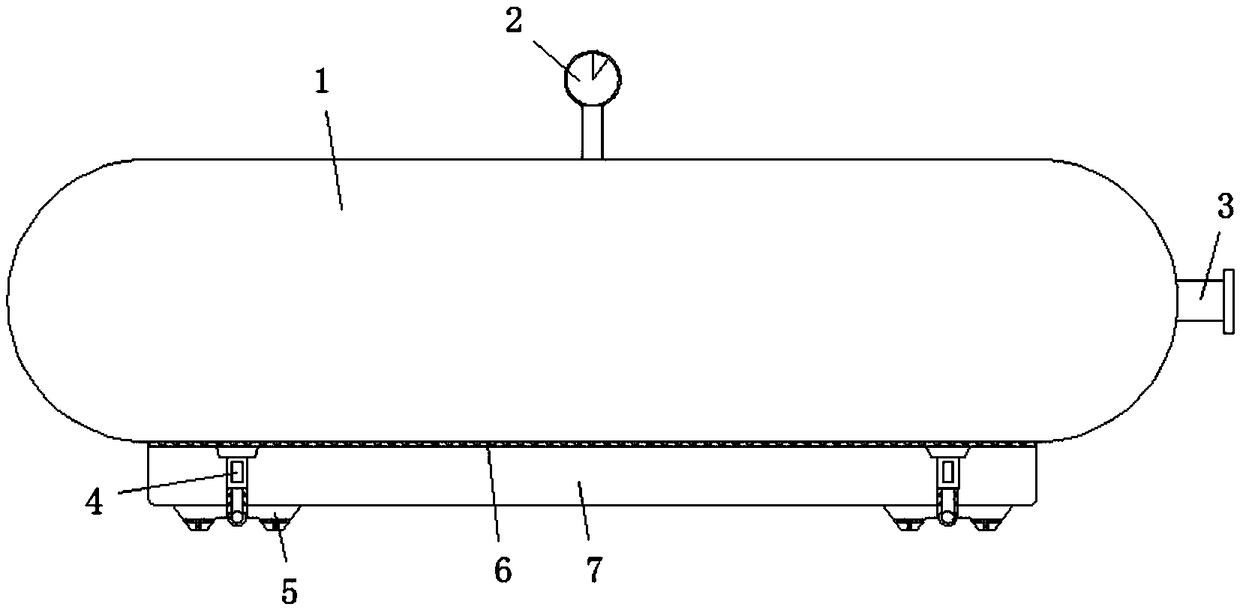

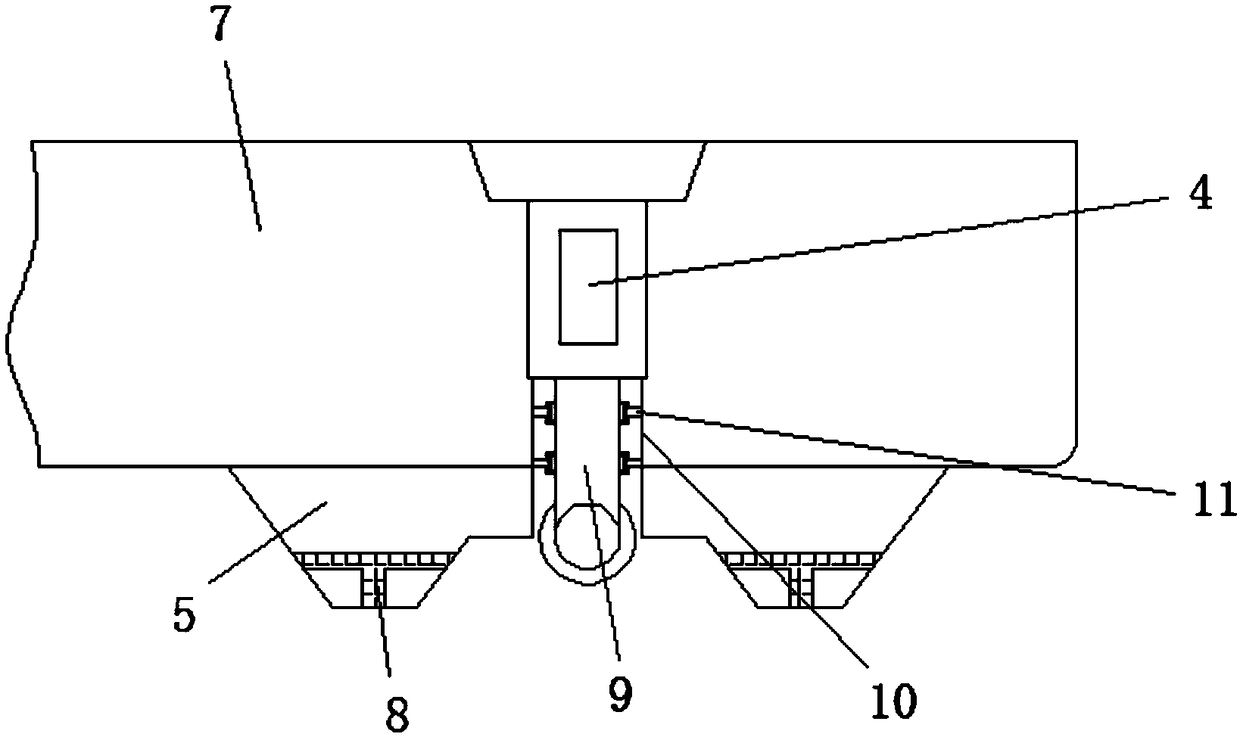

[0027] Example one, reference Figure 1-4 , An industrial pressure vessel that is easy to move, comprising a tank body 1 and a base 7. The upper surface of the base 7 is welded with a tank body 1, and a barometer 2 is set at the center of the upper surface of the tank body 1. The wall is welded with a gas pipeline 3, the bottom of the base 7 is welded with spacer blocks 5 symmetrically on both sides, the top of the inner surface wall of the base 7 is bolted with a driving cylinder 4, and the bottom of the driving cylinder 4 is connected with a connecting rod 9 through a telescopic rod. The bottom of the connecting rod 9 is movably connected with universal wheels 13, the outer walls of the connecting rod 9 are symmetrically provided with sliding grooves 18, and the outer wall of the connecting rod 9 is located on both sides of the sliding groove 18 with symmetrical oil storage pipes 15, and An oil outlet pipe 16 is connected to one side of the outer wall of the oil storage pipe ...

Embodiment 2

[0028] Example two, reference figure 1 with figure 2 , The cross section of the cushion block 5 is a ladder structure, the upper end diameter of the cushion block 5 is larger than the lower end diameter, and the smaller diameter of the lower end facilitates the cushion block 5 to be installed on the ground with low flatness, thereby preventing the pressure vessel from tilting, and The inside of the cushion block 5 is provided with a through hole 8. The cross section of the through hole 8 is a T-shaped structure, and the inner diameter of the through hole 8 is 1-2 cm, so that water stains on the lower surface of the cushion block 5 can enter the through hole 8 inwardly. Side flow away, thereby preventing the accumulation of water stains on the lower surface of the cushion block 5 and affecting the installation stability of the cushion block 5.

Embodiment 3

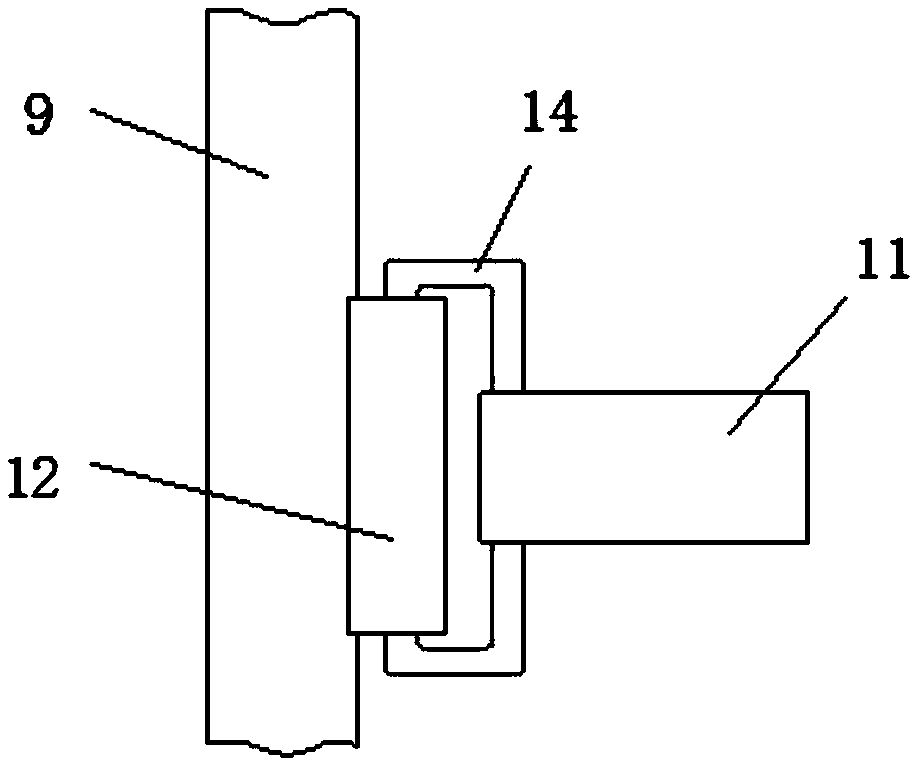

[0029] Example three, reference Figure 1-4 , The outer walls on both sides of the connecting rod 9 are connected to the clamping roller shaft 12 through the sliding groove 18, and the outer diameter of the clamping roller shaft 12 is equal to the inner diameter of the sliding groove 18, and the clamping roller shaft 12 and the sliding groove 18 The rolling connection can play the role of limit clamping on the telescopic movement process of the connecting rod 9 and avoid the phenomenon of offset and shaking of the connecting rod 9.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com