Synchronous clamping water passing device and working method thereof

A synchronous clamping and water-passing technology, applied in pump control, non-variable-capacity pump, machine/engine, etc., can solve the problem of high water pump positioning accuracy, achieve good repeat positioning accuracy, easy to promote, and the overall structure design is simple and reasonable Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described in detail below in conjunction with the accompanying drawings and examples. The following examples are explanations of the present invention and the present invention is not limited to the following examples.

[0023] Example.

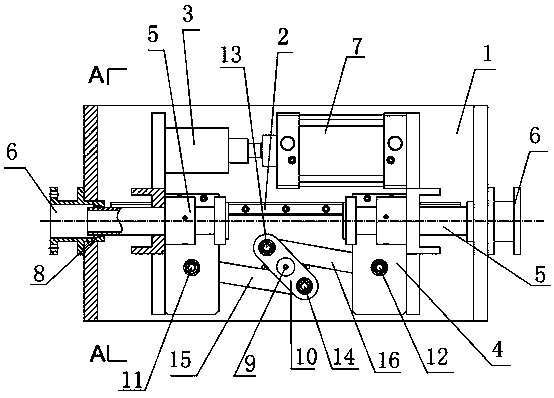

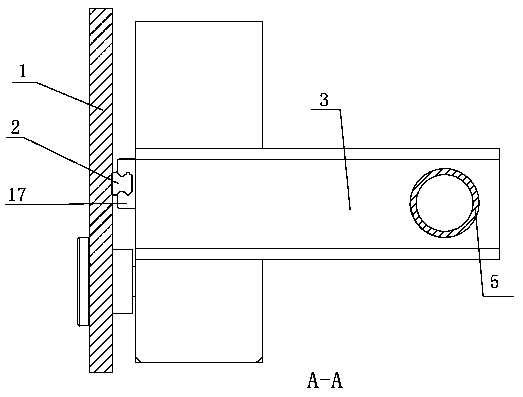

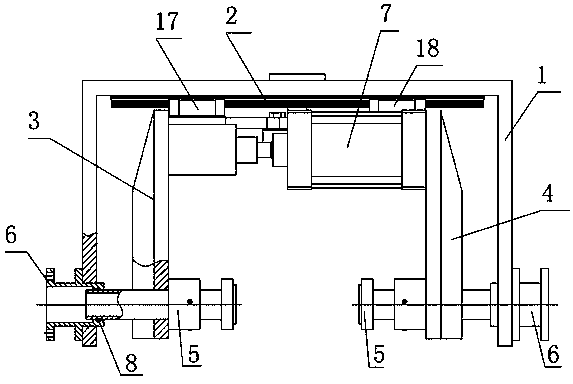

[0024] see Figure 1 to Figure 4 , the present embodiment synchronously clamping water passing device mainly comprises telescopic cylinder 7, fixed hinge shaft 9, rotary lever 10, hinge shaft one 11, hinge shaft two 12, hinge shaft three 13, hinge shaft four 14, connecting rod one 15 and Connecting rod two 16, frame 1, guide rail 2, sleeve pipe 5, flange sleeve pipe 6, left movable frame 3 and right movable frame 4, guide rail 2 is fixed on the frame 1 bottom edge, flange sleeve pipe 6 It is fixed on both sides of the frame 1 and arranged symmetrically. The left movable frame 3 and the right movable frame 4 are respectively fixed with symmetrically arranged bushings 5. After assembly, the two bush...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com