A pulse tube refrigeration system with four-way reversing valve

A four-way reversing valve and refrigeration system technology, which is applied in refrigerators, refrigeration and liquefaction, lighting and heating equipment, etc., can solve the problems of reduced heat transfer coefficient, long rewarming process, and no four-way reversing valve , to meet the needs of cold and heat, convenient temperature control, simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further elaborated below in conjunction with the accompanying drawings and specific embodiments.

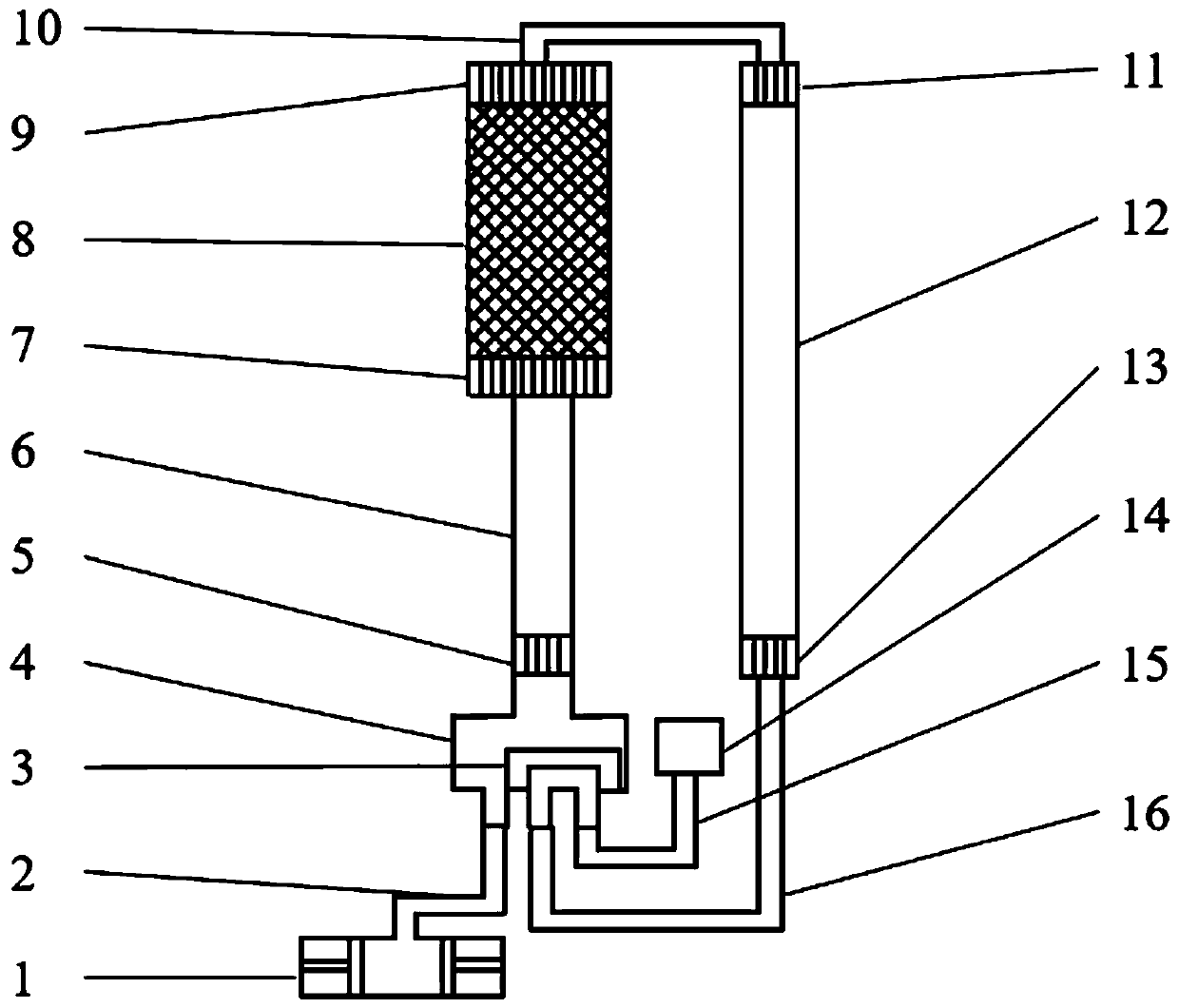

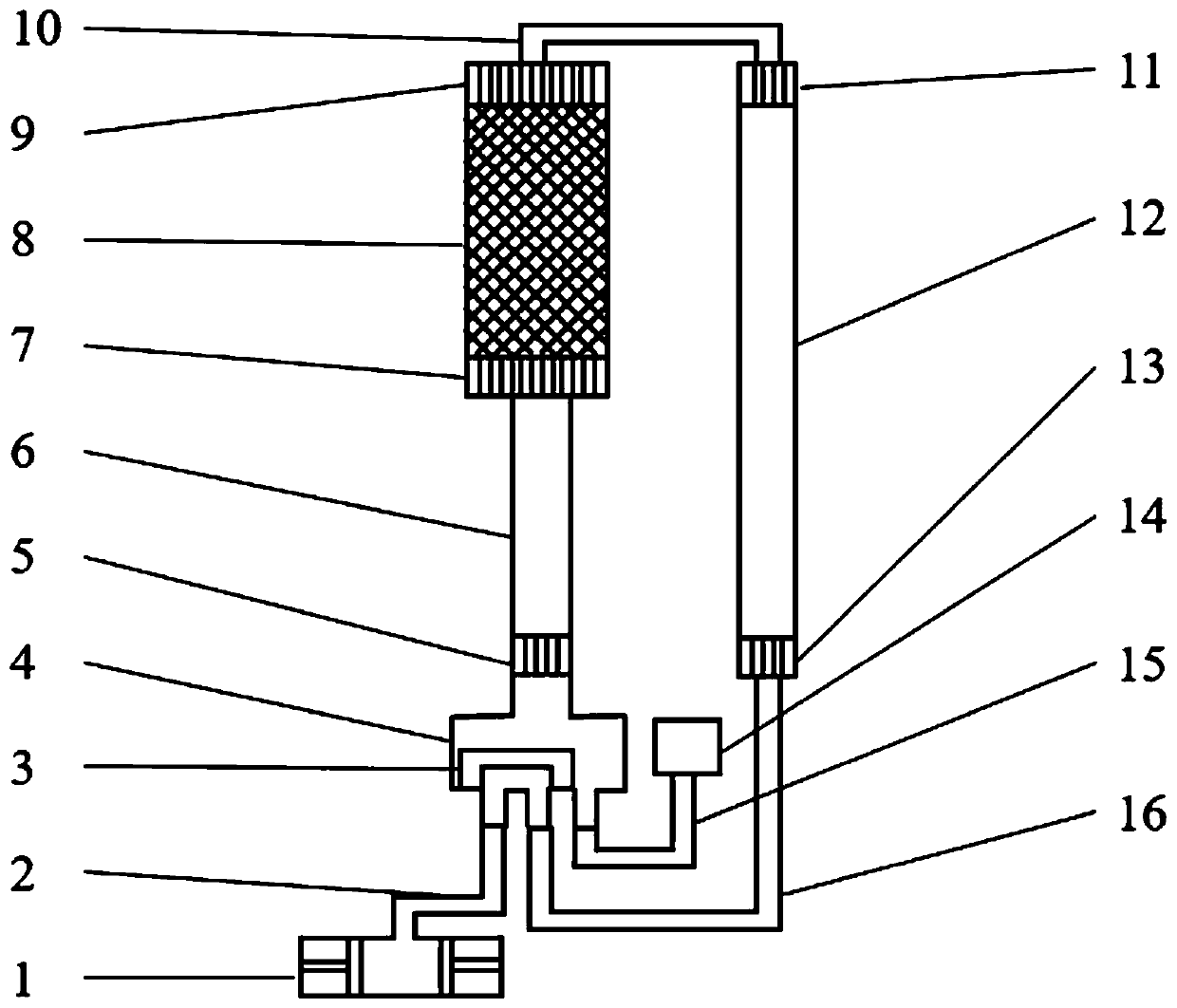

[0032] Such as figure 1 As shown, a pulse tube refrigeration system with a four-way reversing valve includes a four-way reversing valve 4, and the four-way reversing valve 4 is provided with an upper interface, a lower left interface, a lower middle interface and a lower right interface; the lower part The left interface communicates with the compressor 1 through the connecting pipe 2; the lower right interface communicates with the gas storage 14 through the connecting pipe 15; the upper interface connects the first heat exchanger 5, the empty pipe 6, the second heat exchanger 7, and the regenerator in sequence 8. After the third heat exchanger 9 , the connecting pipe 10 , the fourth heat exchanger 11 , the pulse pipe 12 , the fifth heat exchanger 14 and the connecting pipe 16 , they are connected to the lower middle interface.

[0033] In t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com