Consequent-pole motor

A technology of alternating poles and permanent magnet poles, applied in electrical components, electromechanical devices, electric components, etc., can solve the problems of limiting the increase of electromagnetic torque, small reluctance torque, etc., and achieve the effect of improving electromagnetic torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

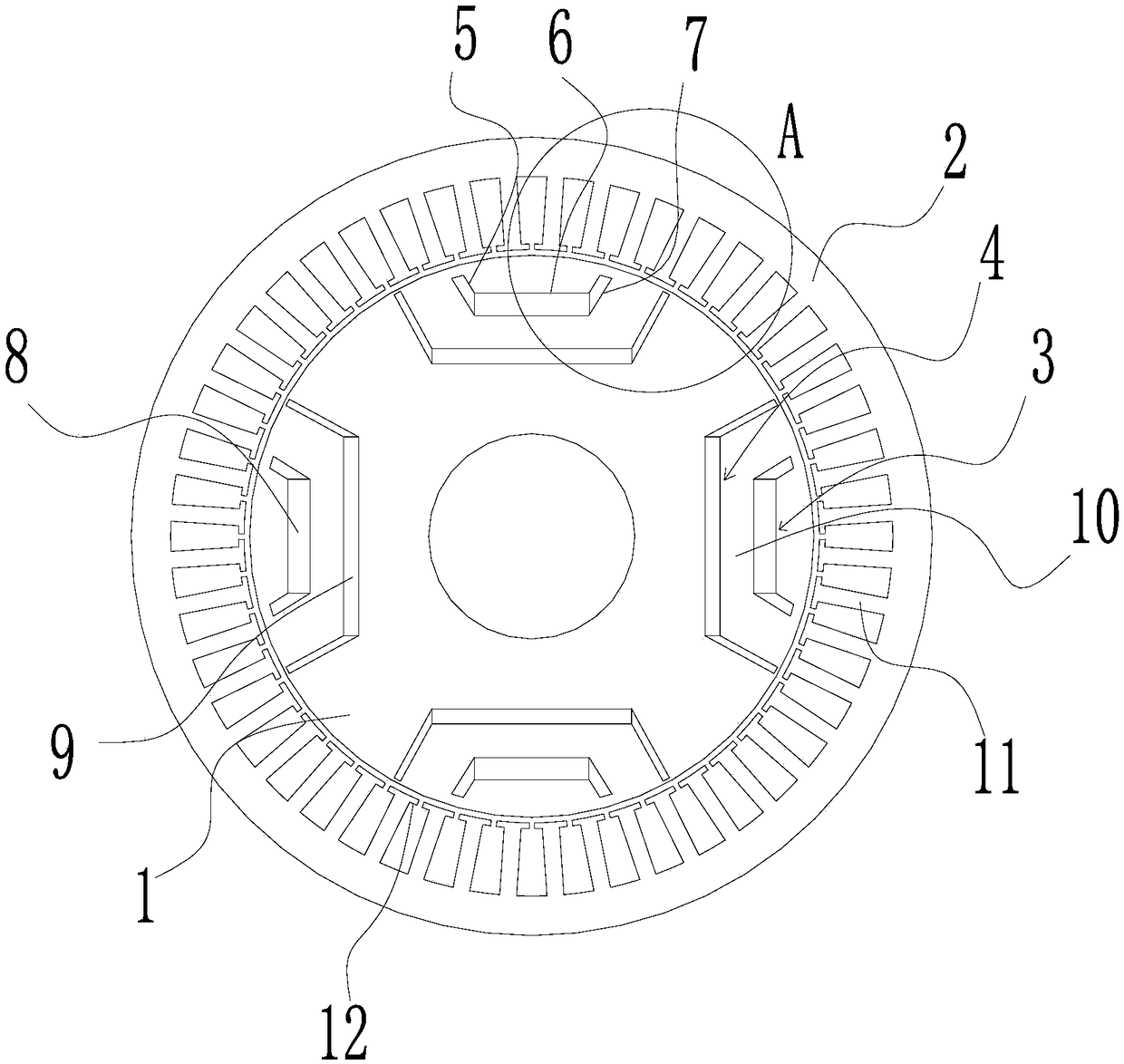

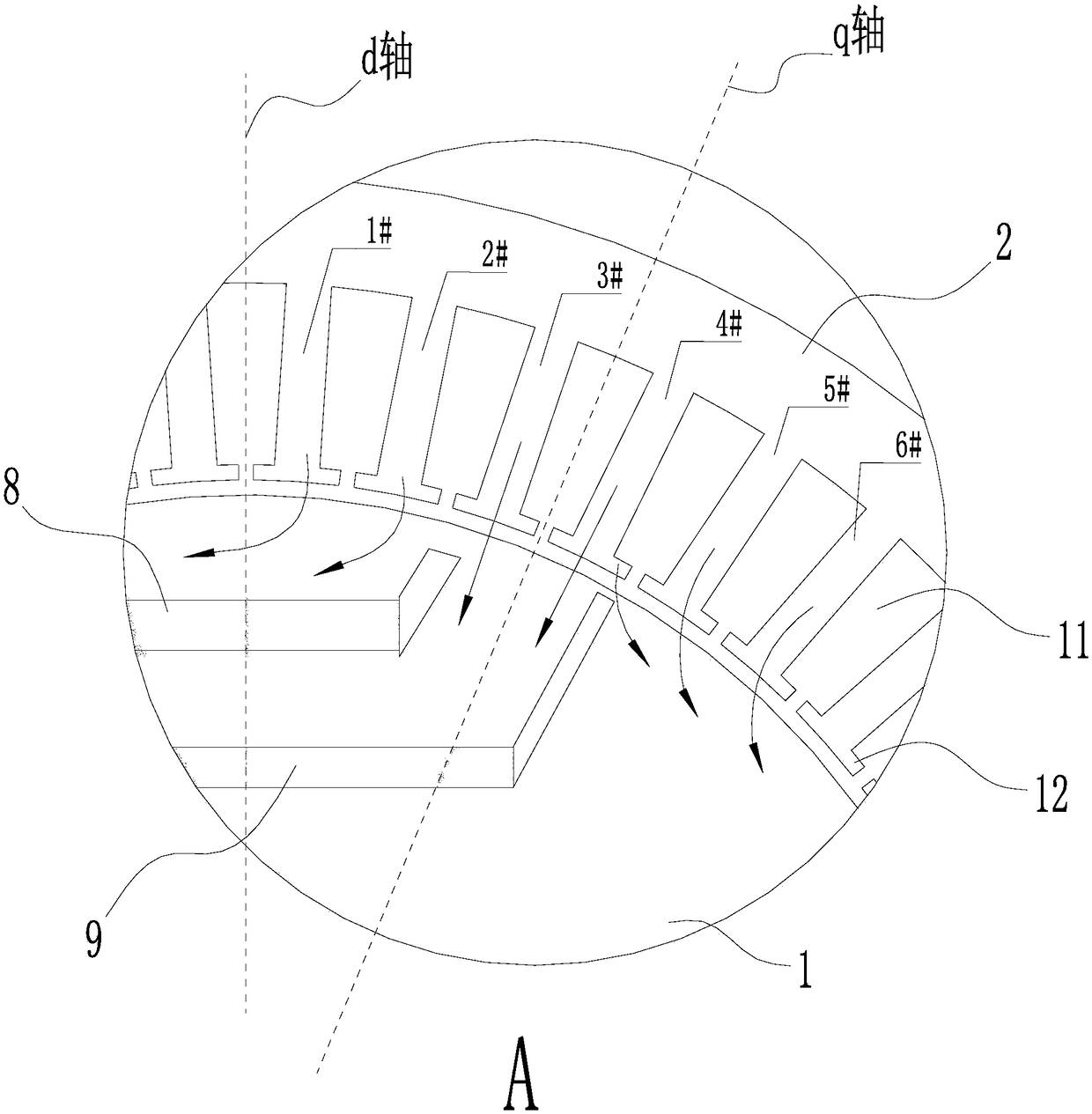

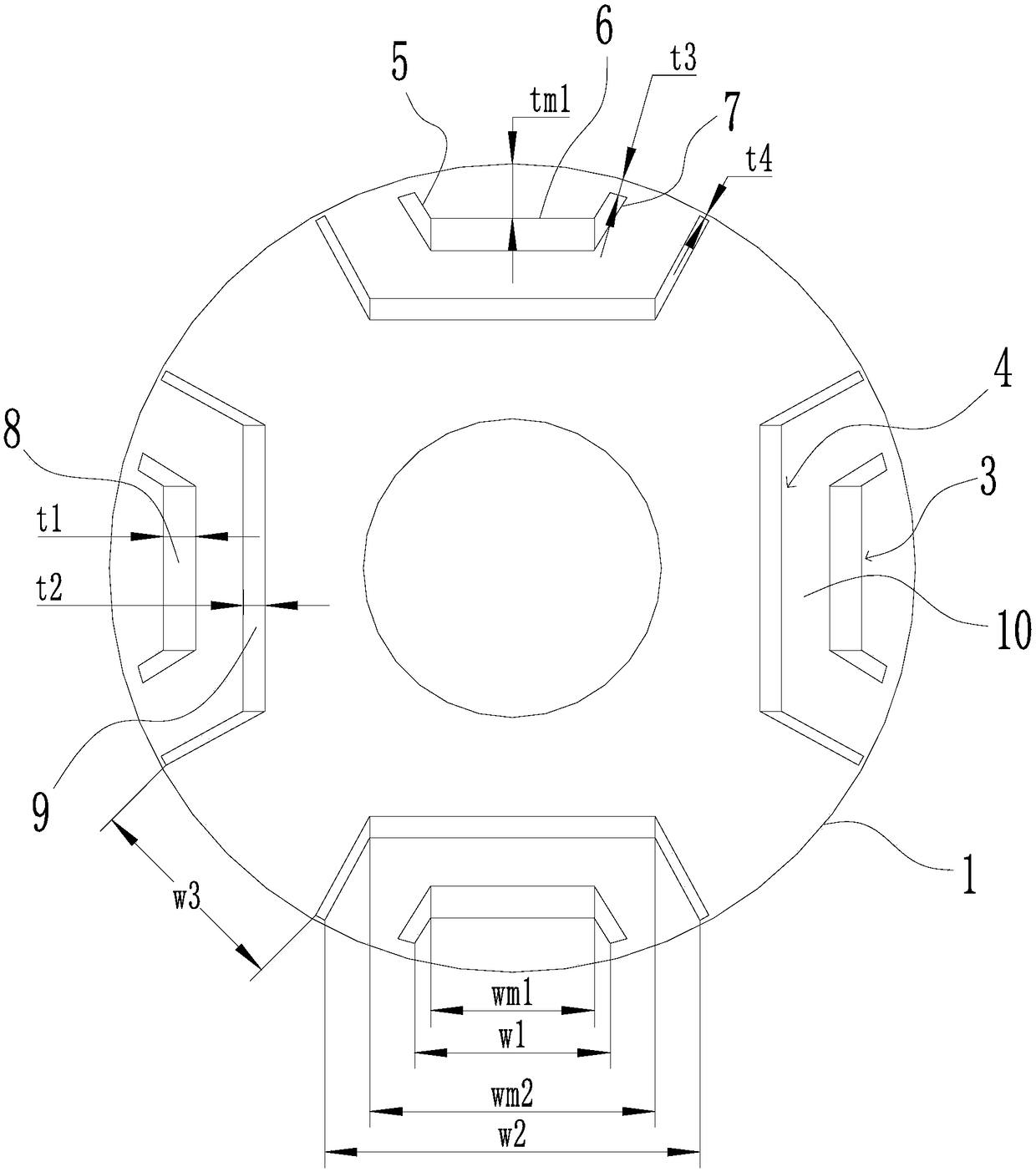

[0050] combined with Figure 1-3As shown, this embodiment provides an alternating pole motor, including a rotor 1 and a stator 2 sleeved outside the rotor 1, and the rotor 1 includes a plurality of permanent magnet poles evenly spaced along the circumference of the rotor 1 , the inner peripheral edge of the stator 2 is provided with a plurality of stator teeth 11 along its circumferential direction.

[0051] In this embodiment, at first the permanent magnet poles of the rotor 1 are improved, as figure 1 and image 3 As shown, the permanent magnet poles of the rotor 1 include a first permanent magnet installation groove 3 and a second permanent magnet installation groove 4 arranged from outside to inside along the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com