Device and method for descaling a moving workpiece

A technology for the direction of movement, the workpiece, applied in the direction of drives for metal rolling mills, cleaning methods using liquids, spraying devices with movable outlets, etc., capable of solving problems such as serious pollution of equipment or its surrounding areas, to optimize energy input Density, energy saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

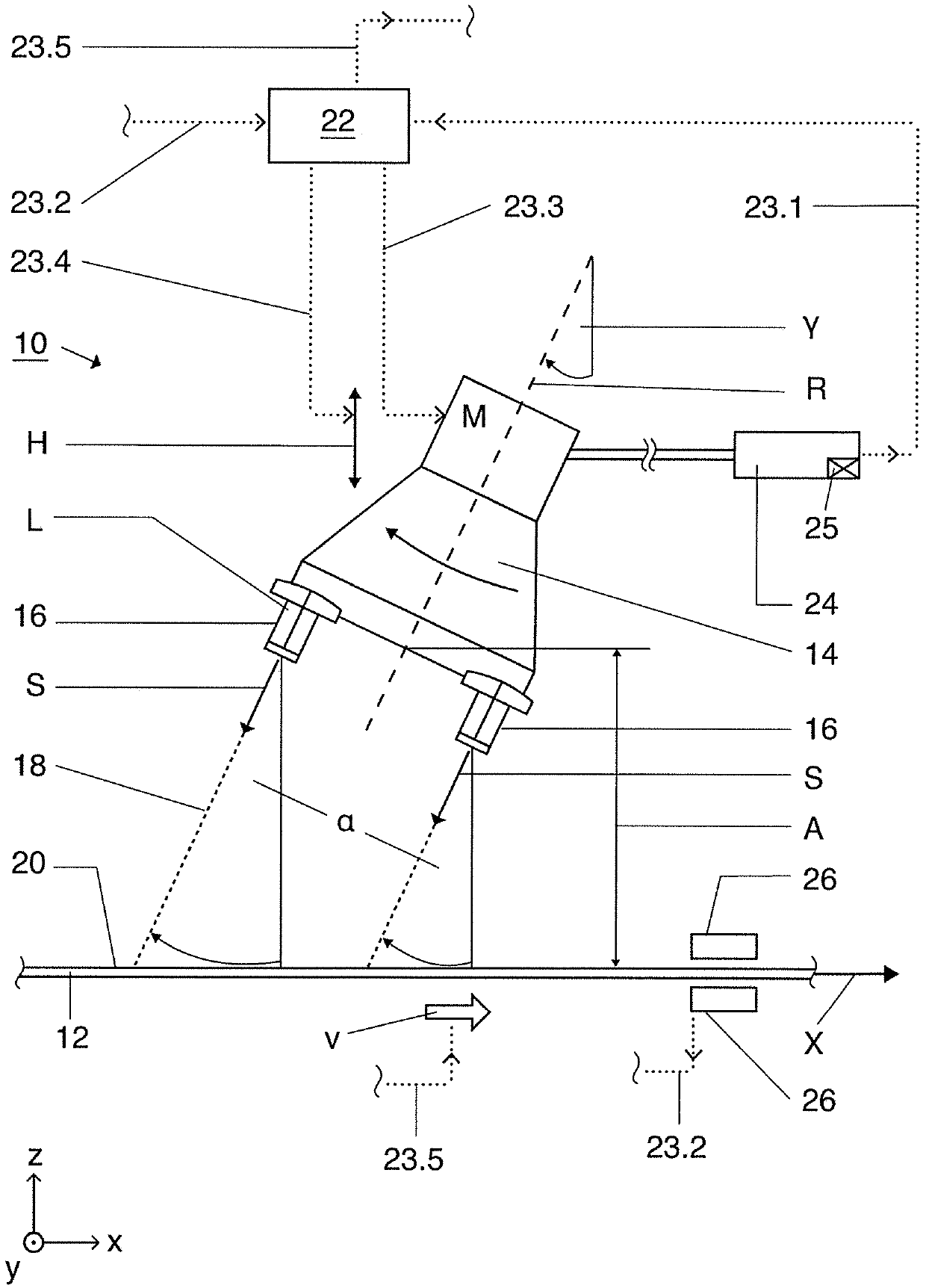

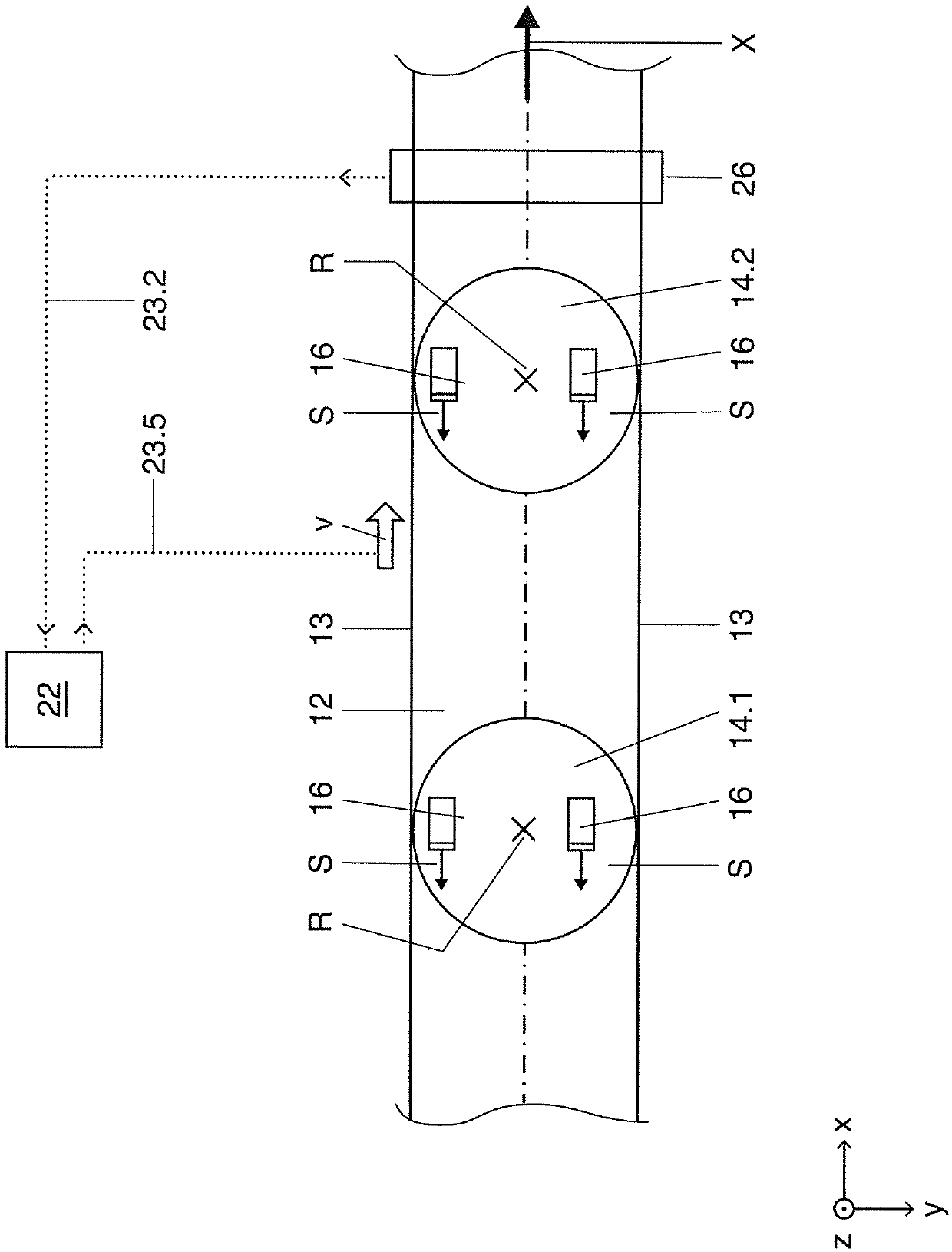

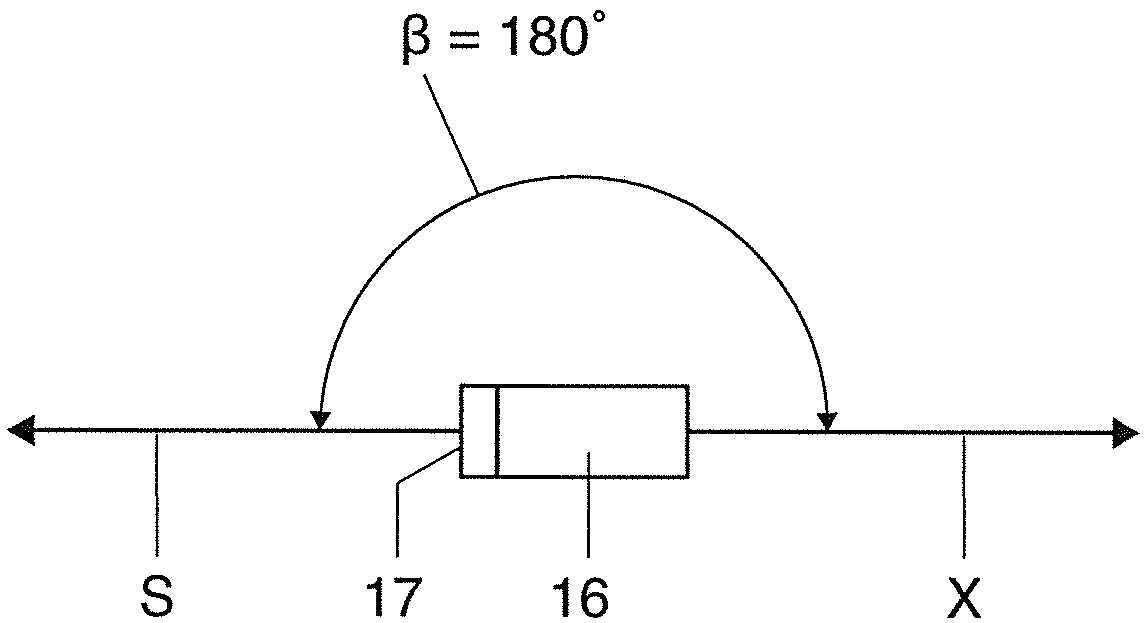

[0031] Refer below Figure 1 to Figure 6 Various embodiments of the present invention will be described in detail. In the drawings, the same technical features are correspondingly denoted by the same reference numerals. Furthermore, it should be pointed out that the representation in the drawings is basically simplified and in particular not shown to scale. In some of the figures, a Cartesian coordinate system is drawn in order to spatially orient the device according to the invention with reference to the workpiece to be descaled and moved.

[0032] The device 10 according to the invention is used for descaling a workpiece 12 which is moved relative to the device 10 in the direction of movement X. FIG. The workpiece may be a hot rolled piece of the moving bypass device 10 .

[0033] The device 10 according to the invention has a jet nozzle assembly with a plurality of jet nozzles from which a liquid, in particular water, is ejected at high pressure onto the surface of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com