Tire pressure checking system for a vehicle

A tire pressure and monitoring system technology, applied in tire measurement, vehicle parts, tire parts and other directions, can solve problems such as increasing difficulty, and achieve the effect of reducing production costs and reducing the number of components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

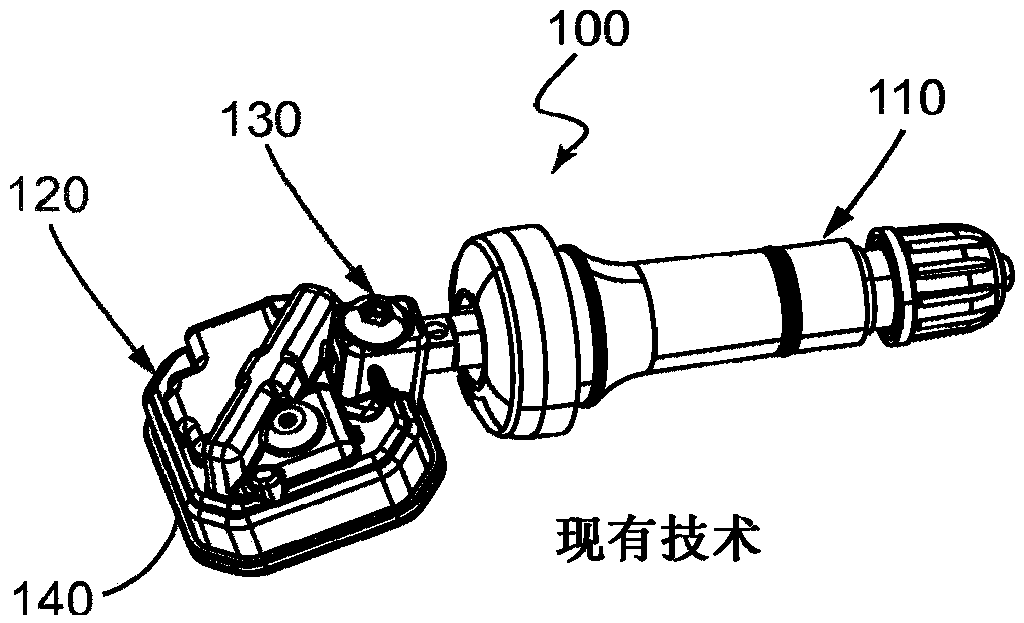

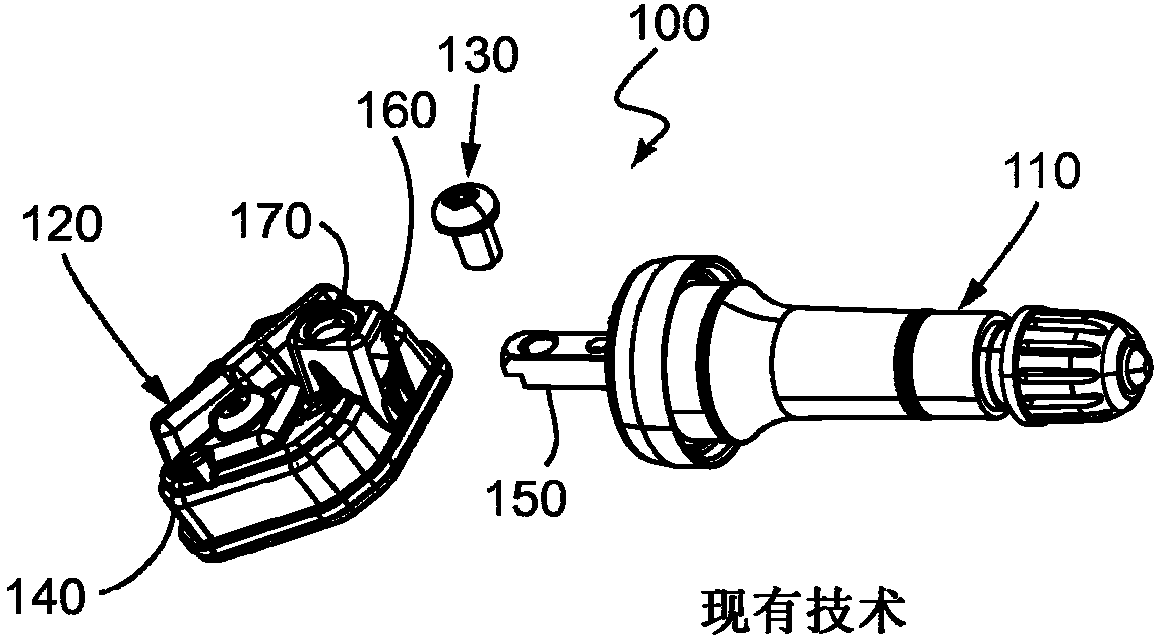

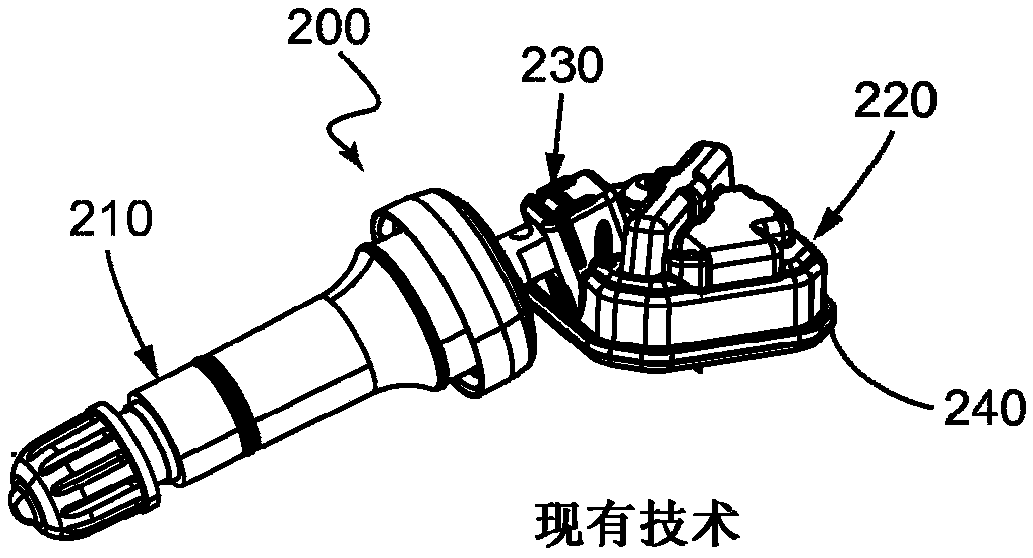

[0050] exist Figure 5 to Figure 14 A tire pressure monitoring system 10 according to a first embodiment of the invention is shown in . The tire pressure monitoring system 10 can be used in a known manner in a vehicle and is used for ascertaining tire-specific parameters such as, for example, air pressure or temperature. exist Figure 5 The tire pressure monitoring system 10 shown in includes a valve body 11 and a tire pressure sensor 12 . The tire pressure sensor 12 has a housing 14, in Image 6 The details of which are shown in , in or on which are arranged a mechanism 15 for determining at least one tire-specific parameter and wirelessly transmitting the at least one tire-specific parameter to the controller on the vehicle side (in Image 6 exemplarily sensor 15). The housing 14 has a fastening region 16 , which rises from the housing 14 in the form of a chimney and serves for the fastening of the valve body 11 .

[0051] fastening area 16 included in the Figure 7 wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com