A-shaped bilge keel

A bilge keel and font technology, which is applied in the field of A-shaped bilge keels, can solve the problems of difficult positioning and operation, and achieve the effects of concise structural design, simplified structure and reduced number of components.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Embodiment one (comparative example):

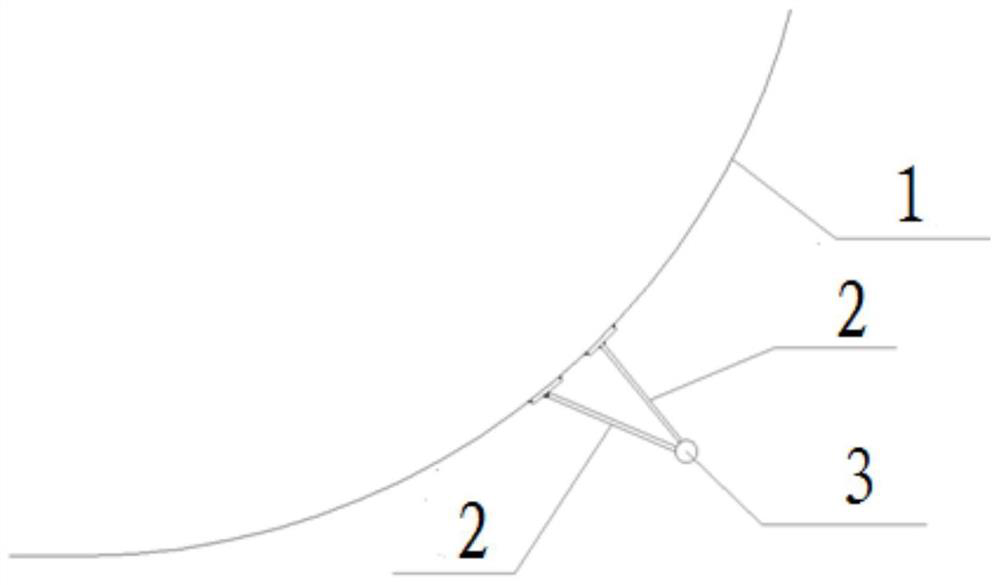

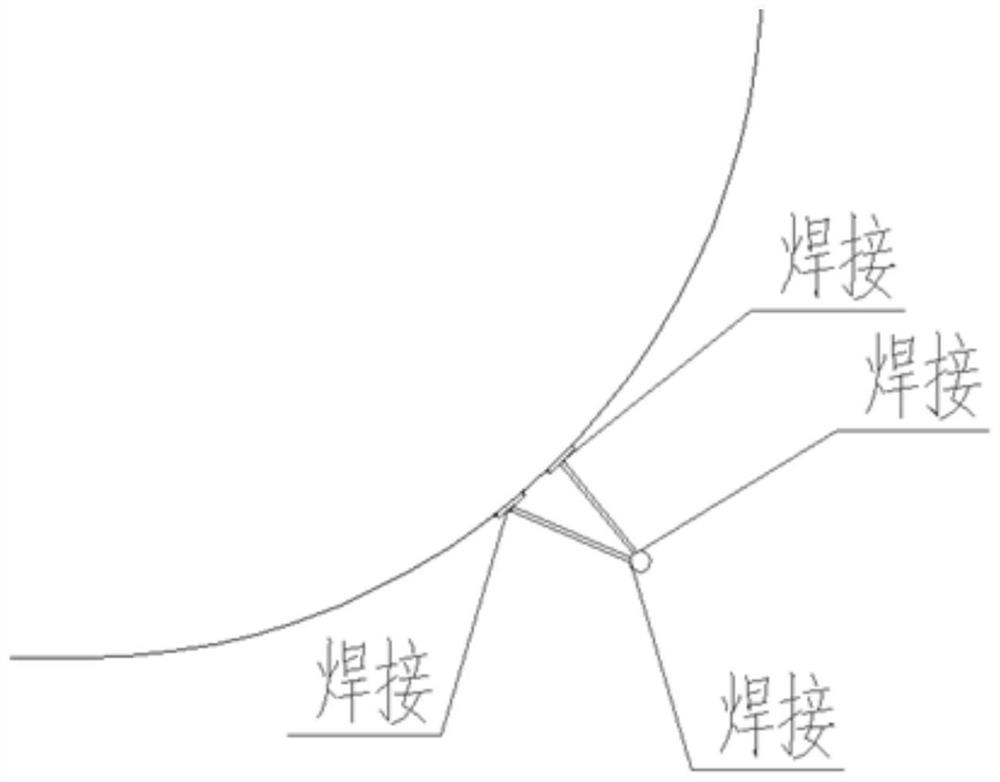

[0026] see Figure 1-Figure 2 , the existing A-shaped bilge keel used for comparison mainly consists of two plates 2 and a round steel 3. From figure 2 It can be seen that the round steel 3 needs to be welded with the two plates 2 at the same time. The surface of the round steel is arc-shaped, and the positioning on both sides is difficult, and the positioning and operation during welding are relatively difficult.

Embodiment 2

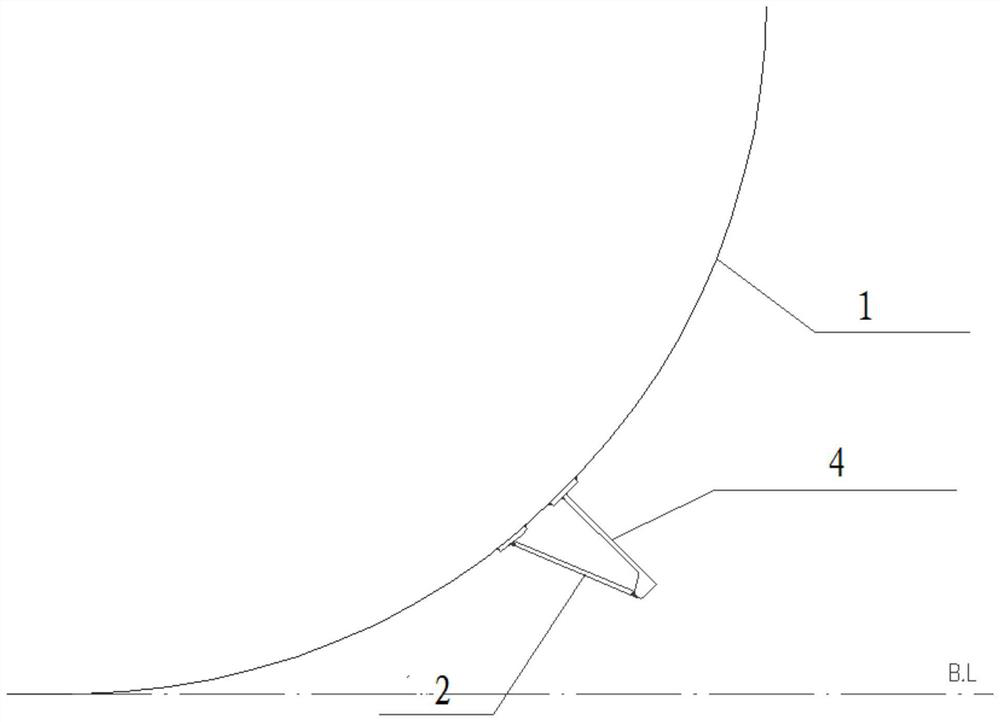

[0028] see Figure 3-4 , an A-shaped bilge keel, comprising a flat bulb steel 4 and a plate 2; the straight end of the flat bulb steel 4 is fixedly connected to the hull 1; one end of the plate 5 is fixedly connected to the hull 1, and the other end is fixed to the hull 1. The convex end of the flat bulb steel 4 is welded and fixed; the cross section of the flat bulb steel 4 and the plate 2 forms an A-shaped angle.

[0029] see Figure 4 , two auxiliary connecting plates are welded and fixed on the hull 1, the flat end of the bulb flat steel 4 is welded and fixed to one of the auxiliary connecting plates, and the plate 2 is welded and fixed to the other auxiliary connecting plate.

[0030] see Figure 4 , the end of the protruding end of the bulb flat steel 4 is welded and fixed to the plate 2 .

[0031] see Figure 3-4 , the thickness of the raised end is greater than the thickness of the straight end.

[0032] see Figure 3-4 , the plate 2 is located below the bulb fla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com