USB (universal serial bus) 3.0 connector and manufacturing method thereof

A technology of connectors and contact pieces, applied in the direction of connection, fixed/insulated contact components, circuit/collector components, etc., can solve the problems of increased defective rate, many manufacturing steps, poor production efficiency, etc., and reduce the number of components , Reducing manufacturing steps and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0064] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

[0065] Before going into details, it should be noted that the relative positional terms used in the entire specification, such as "front and rear direction X", "left and right direction Y", "top and bottom direction Z", are based on the normal use orientation and each figure. The direction shown is the reference.

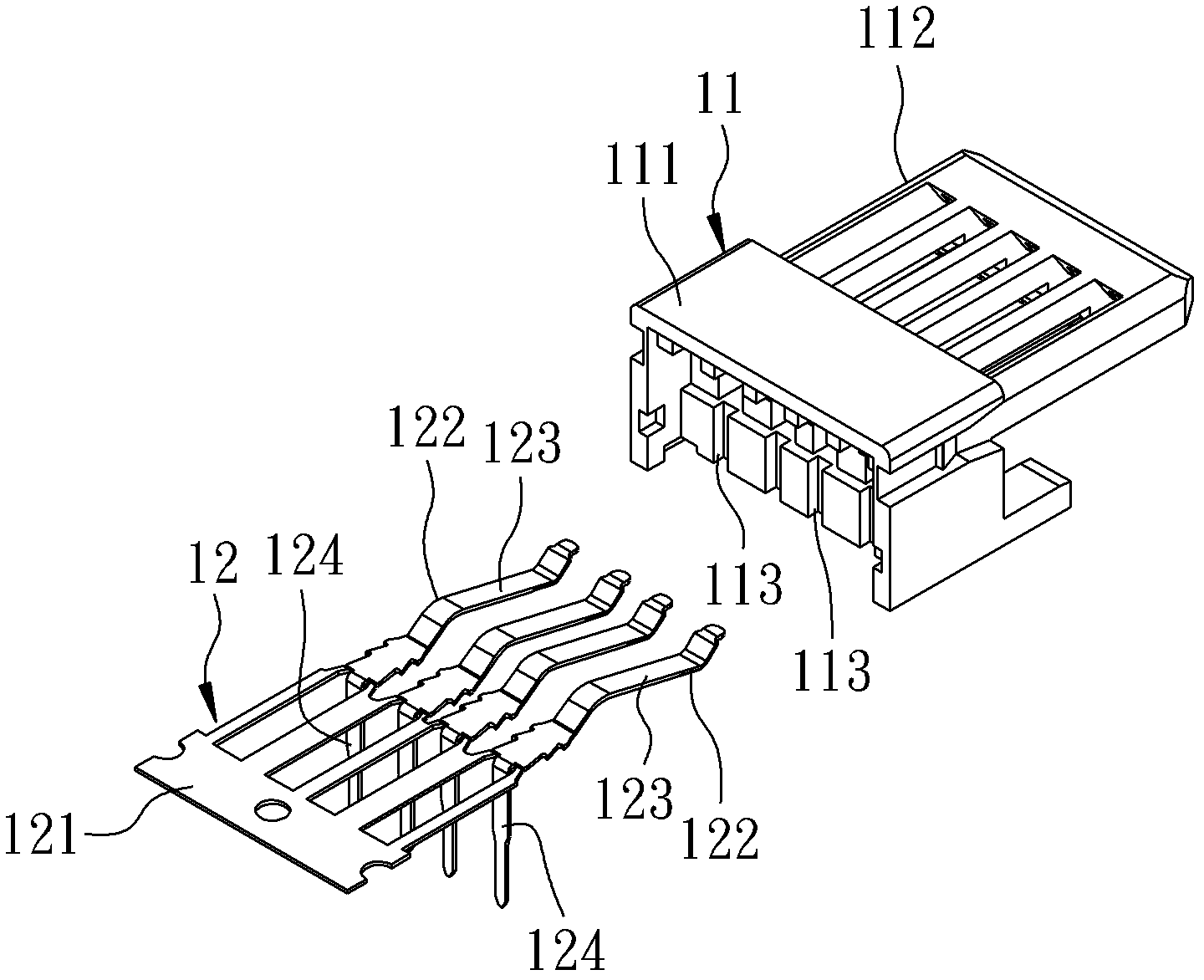

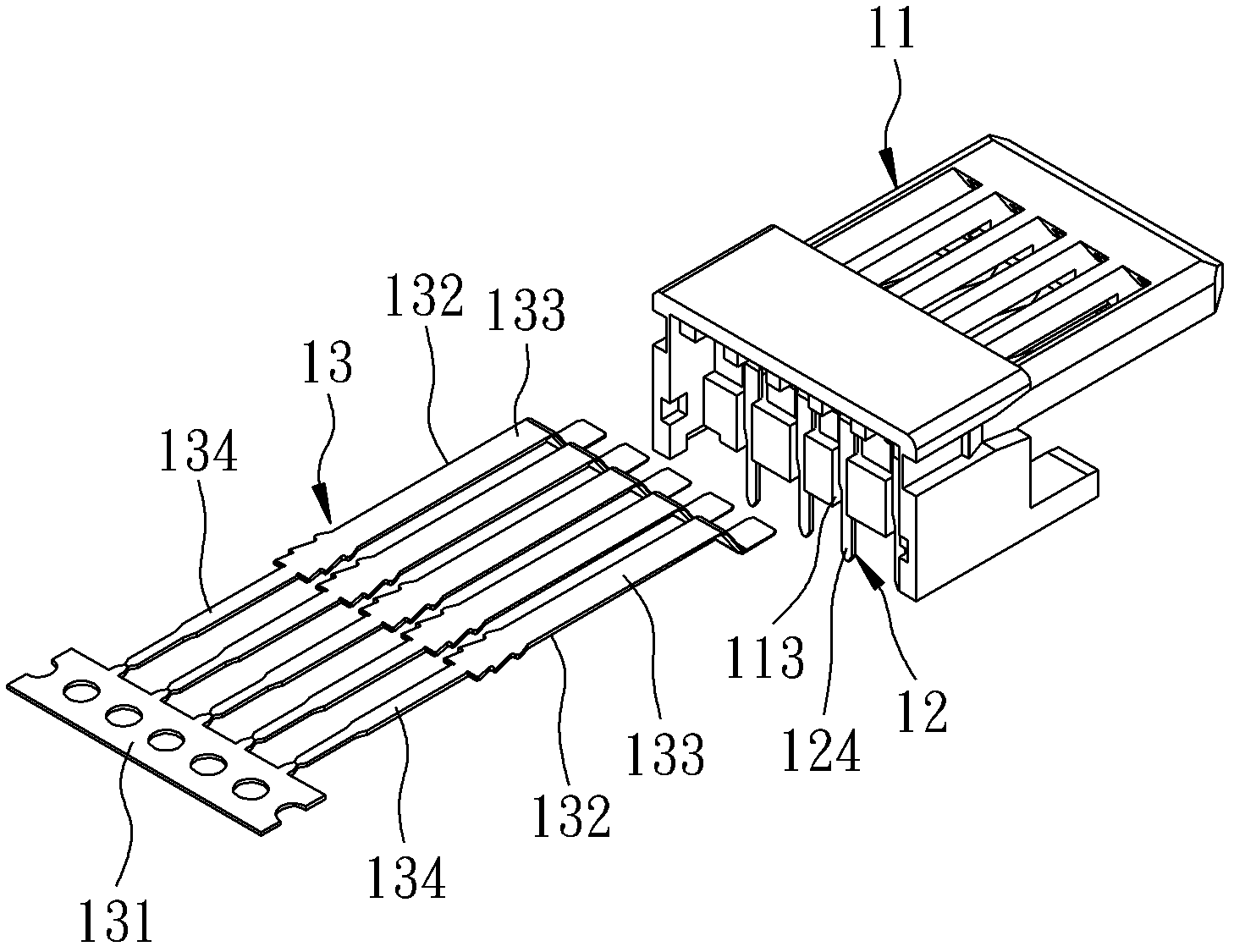

[0066] Such as Figure 12 As shown, the preferred embodiment of the USB3.0 connector of the present invention includes an insulating body 30 , a first terminal unit 40 , a second terminal unit 50 , a housing 60 and a rear cover 70 .

[0067] Such as Figure 12 to Figure 17 As shown, the insulating body 30 includes a base 31, a tongue block 32 extending from the base 31 toward the front end, a clamping block 33 formed from the bottom end of the base 31 toward the front end, and a 31 and a receiving groove 34 formed by a top block 311, a b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com