Efficient screening equipment

A screening material and high-efficiency technology, applied in the direction of screening, solid separation, grille, etc., can solve the problems of low efficiency, uneven sand screening machines, etc., and achieve the effect of good sand screening effect and high sand screening efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

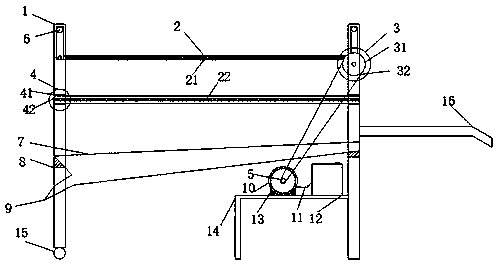

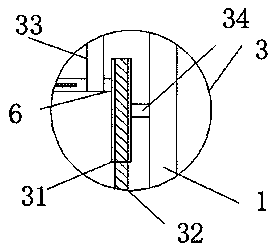

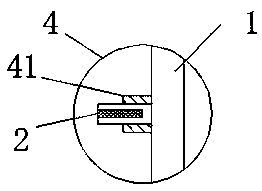

[0017] see figure 1 As shown, the movable rod 33 is rotationally connected with the frame leg 1 through the movable wheel 6, and the primary screen 21 is connected with the movable rod 33 through the rotating mechanism 3. The mesh distance of the primary screen is slightly larger, in order to allow more impurities The faster sieving of the former sand material, the rotating mechanism 3 includes a driven wheel 31, a belt 32, a movable rod 33 and a connecting shaft 34, and the rotating mechanism 3 is driven by the engine 10 to make the screen cloth do periodic motion. The secondary screen 22 is slidingly connected with the frame leg 1 through the inserting plate structure 4. The mesh distance of the secondary screen 22 is relatively small, and is used to block the finer impurities that are not filtered out by the primary screen 21, and pass through the inserting plate structure. Can be pulled out for cleaning. The sand-collecting funnel 7 is fixedly placed on the bridge 8 of th...

Embodiment 2

[0019] see Figure 2-3 As shown, the driven wheel 31 is fixedly connected to the frame leg 1 through the connecting shaft 34 , and the movable rod 33 is rotationally connected to the primary screen 21 through the movable wheel 6 . The driving wheel 5 is rotationally connected to the driven wheel 31 through a belt 32 . The engine 10 drives the driving wheel 5 to rotate, thereby driving the driven wheel 31, and the primary screen 21 moves periodically around the driven wheel 31 to realize preliminary filtration of raw sand. The flashboard structure 4 includes a support 41, and the secondary screen 22 is in a sliding connection with the support 41, and can be pulled out for cleaning when cleaning impurities on the secondary screen 22.

[0020] The building sand screening machine of the present invention adopts an automatic double filter design, pours the raw sand material into the primary screen 21, and is driven by the engine 10 to perform periodic motions to filter out larger ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com