A Sand Screening Equipment for Intermittent Feeding

An intermittent, sand-screening technology, applied in the fields of sieving, solid separation, loading/unloading, etc., can solve the problems of poor screening effect, large area of screening equipment, unfavorable transfer, etc., to improve work efficiency, avoid waste, Good effect of sieving sand

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

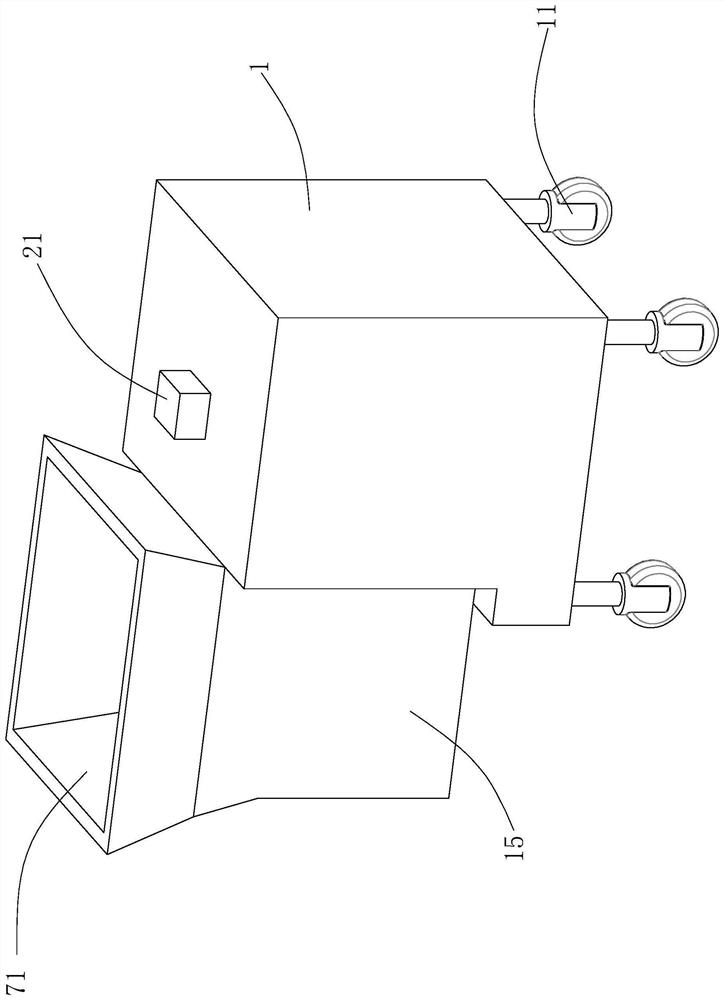

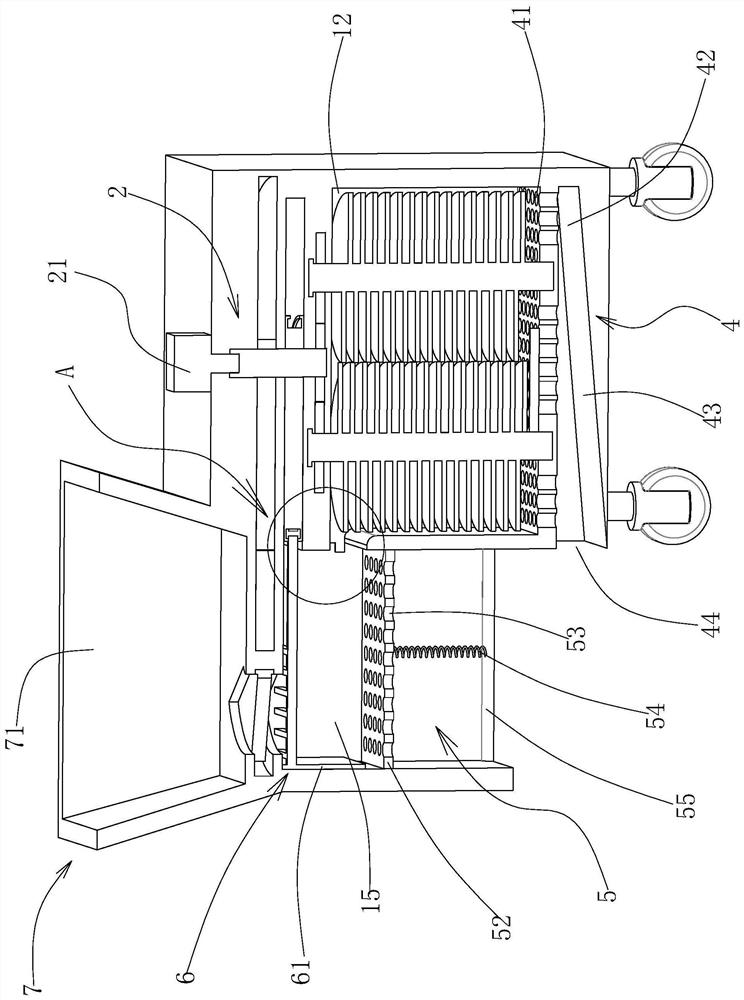

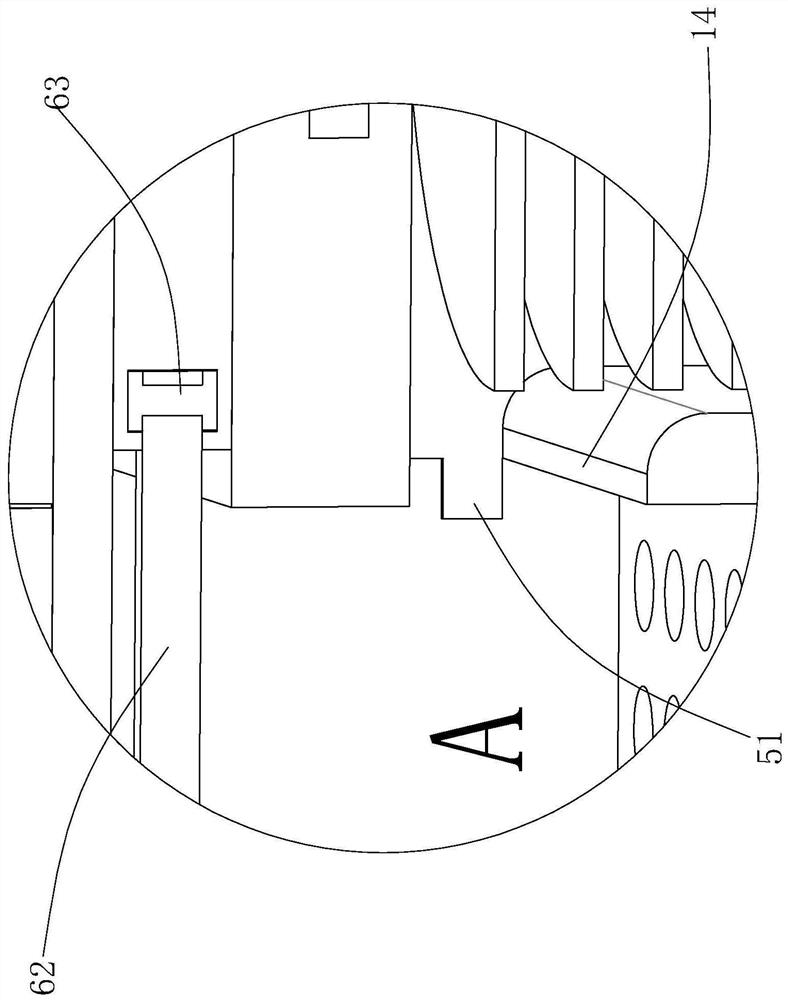

[0024] like figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 As shown, a sand screening equipment for intermittent feeding includes a box body 1 with wheels 11 installed at the lower end, and is characterized in that: the upper end of the box body 1 is provided with a driving device 2, and the lower end of the driving device 2 is provided with a grinding device 3, The lower end of the grinding device 3 is provided with a secondary sand screening device 4, and the grinding device 3 is installed in the coarse sand processing bin 12, and one side of the coarse sand processing bin 12 is connected to the primary sand screening bin 15 through the coarse sand feeding port 14, And the primary sand screening bin 15 is fixedly connected with the box body 1, the primary sand screening bin 15 is provided with a primary sand screening device 5, the upper end of the primary sand screening device 5 is provided with a push plate device 6, and the upper end of the push plate device 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com