Fixture tool for water knockout drum valve body

A water separator and valve body technology, applied in the mechanical field, can solve the problems of low assembly efficiency of water separators and consistent orientation of branch pipe joints, and achieve good fixing effect, improved assembly efficiency, and good positioning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

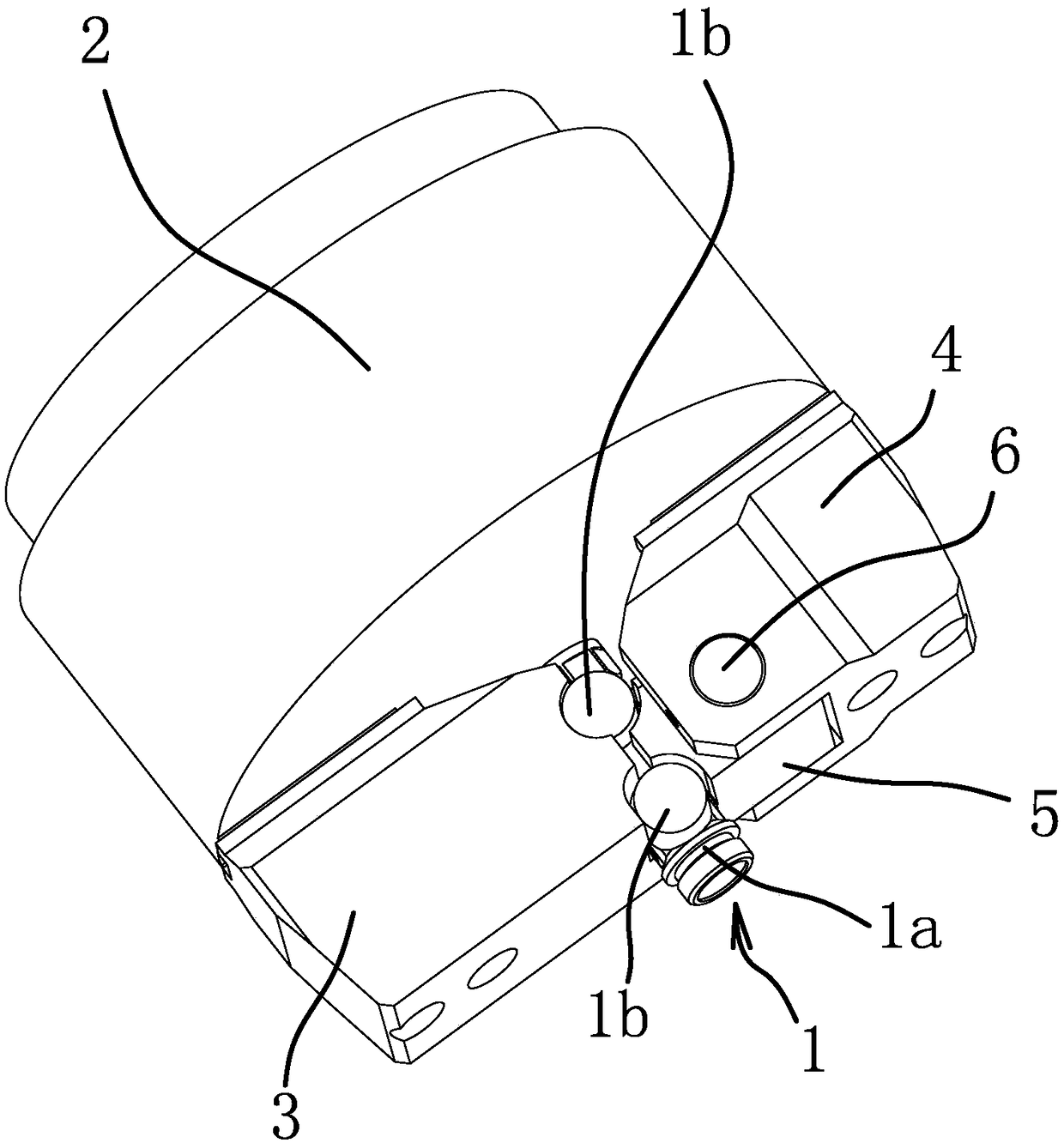

[0042] like figure 1 As shown, a water distributor valve body includes a main pipe 1a, and two protruding valve core joints 1b are arranged on the outer surface of the main pipe 1a.

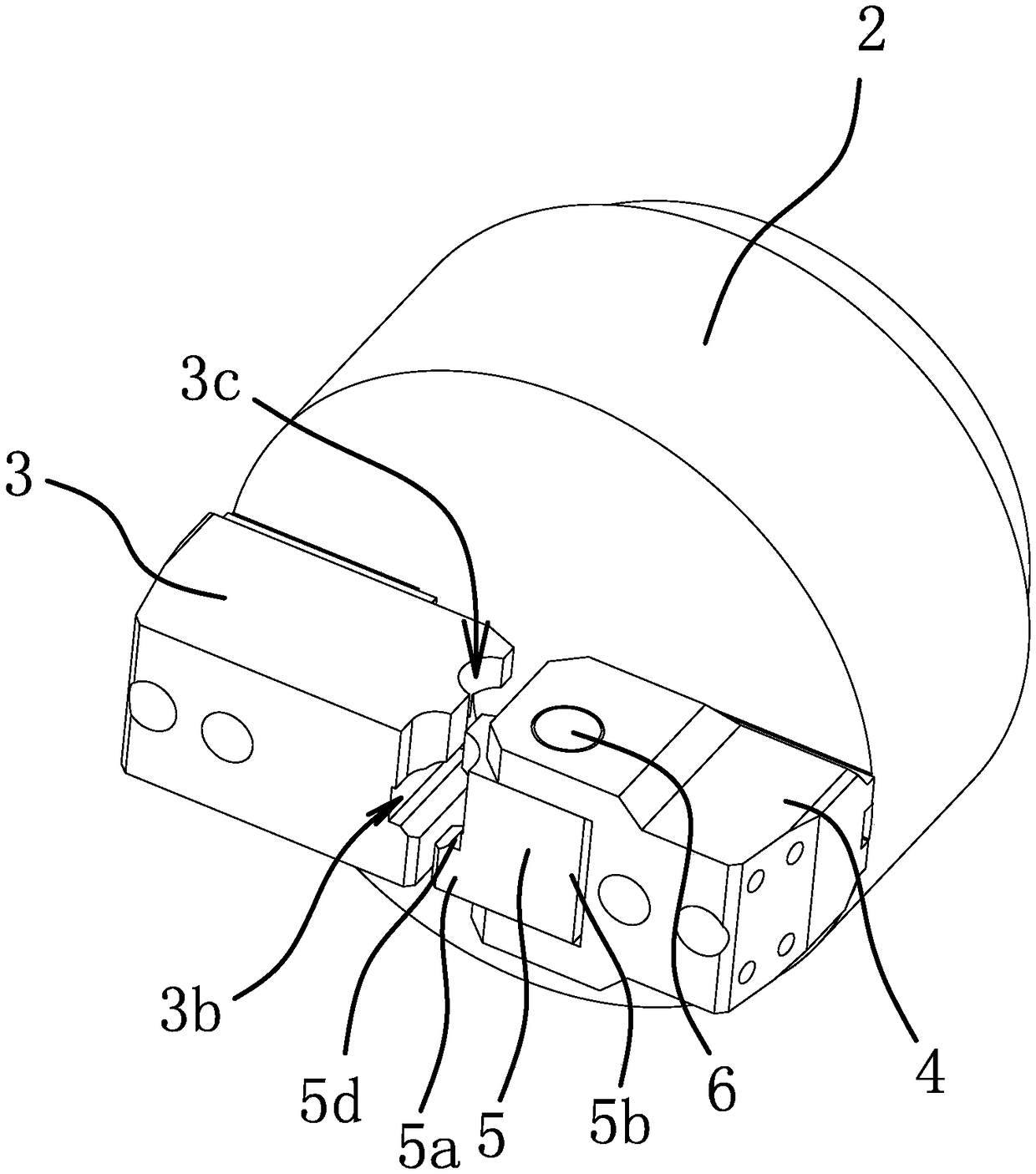

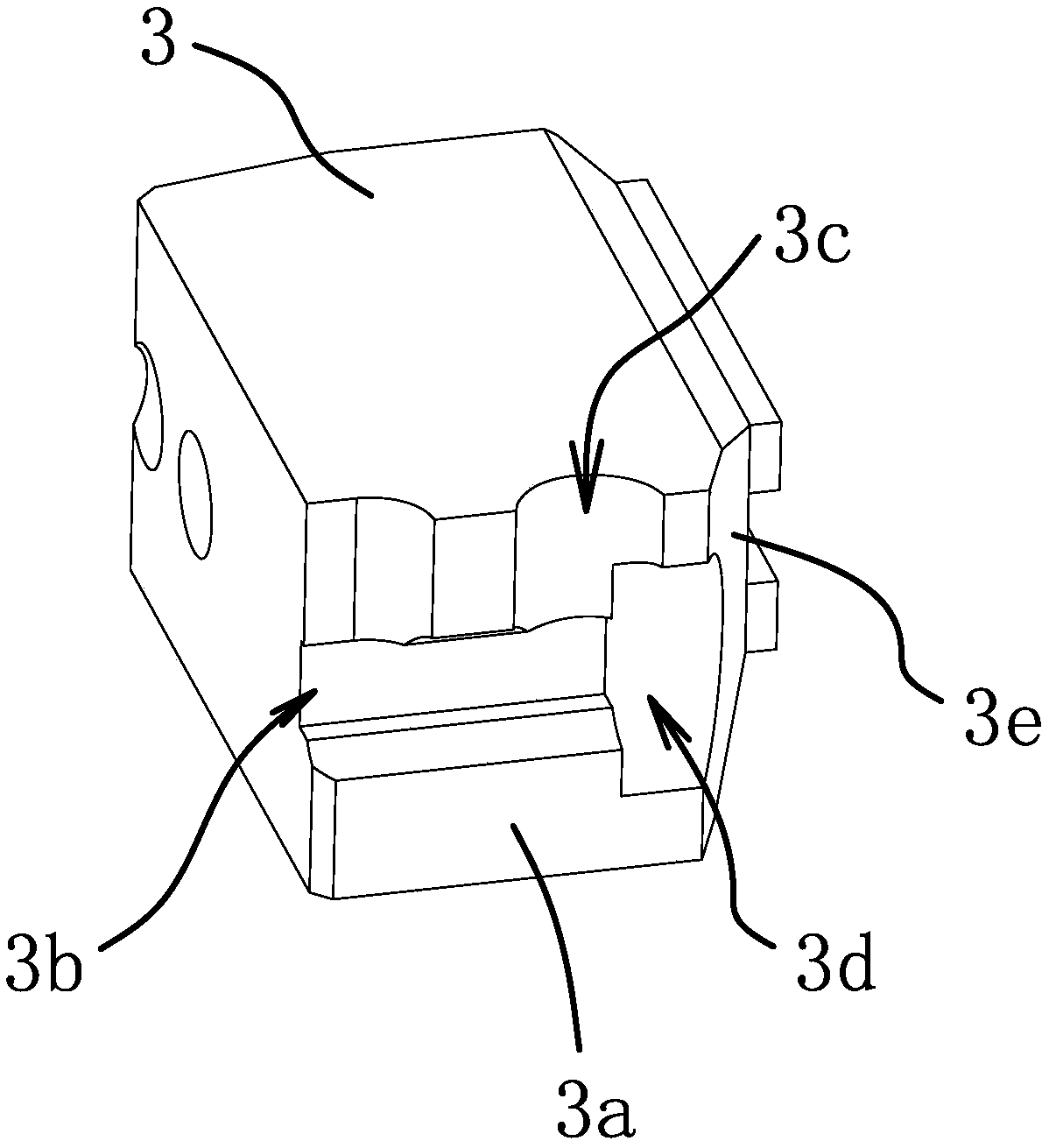

[0043] like Figure 1-Figure 5 As shown, a fixture tooling for a water distributor valve body includes a chuck 2, and the front end of the chuck 2 is connected with a jaw one 3 and a jaw two 4 for fixing the water distributor valve body, the chuck 2 and the machine tool The main shaft is connected, the first jaw 3 is fixed on the chuck 2, and the second jaw 4 can be close to or far away from the first jaw 3. The side opposite to the claw two 4 on the claw one 3 is the clamping surface one 3a, and the clamping surface one 3a is provided with a positioning groove one 3b extending in the axial direction and a positioning groove two 3c intersecting and communicating with the positioning groove one 3b . When clamping the valve body 1, the main pipe 1a is embedded in the first positioning groove 3b,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com