Transmission device used for optical cable repeated bending testing machine

A transmission device, repeated bending technology, applied in measuring devices, using repeated force/pulse force to test the strength of materials, instruments, etc., can solve the problems of motor burnout, excessive forward and reverse times, etc., and achieve reliable movement and simple structure. , the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

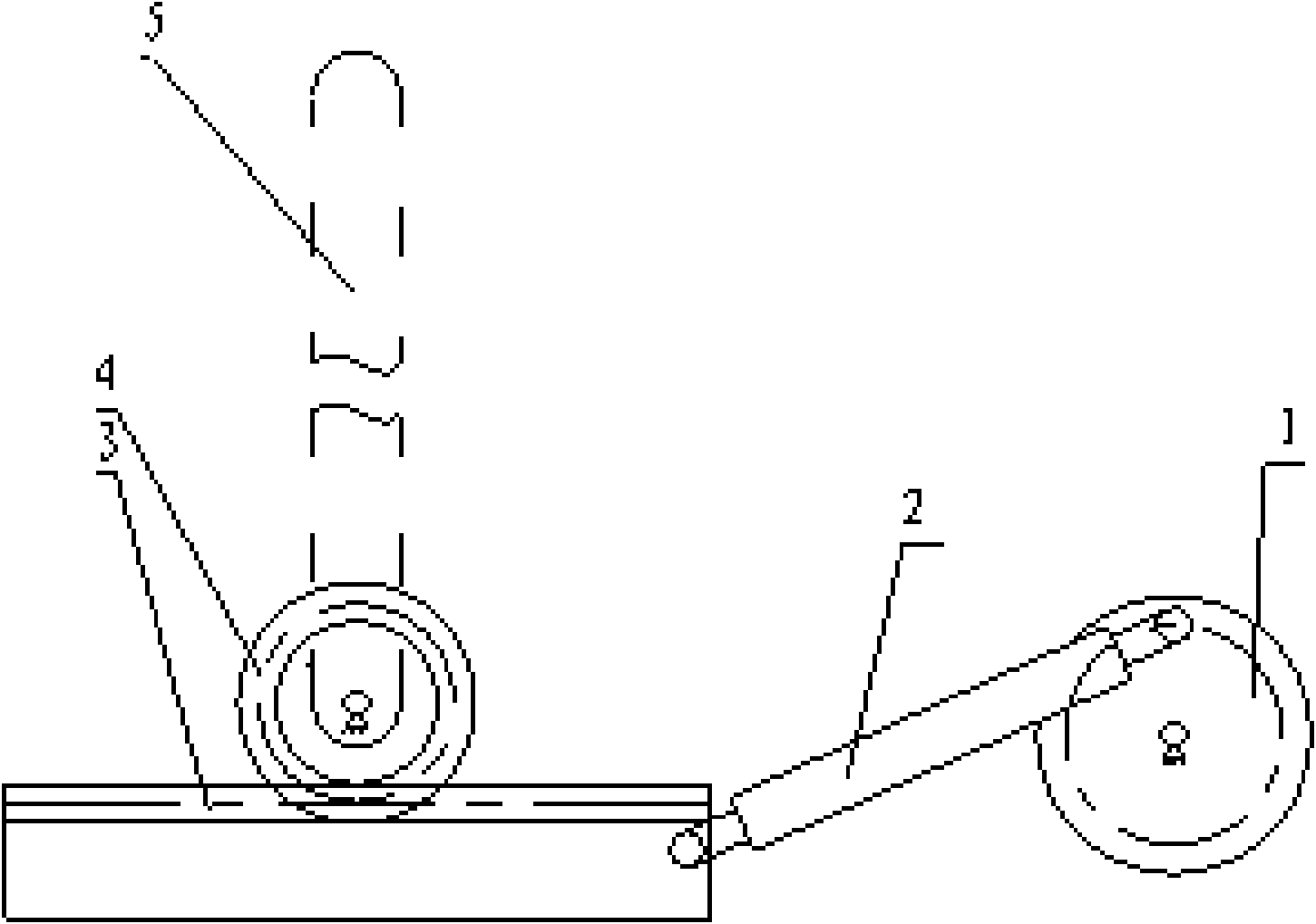

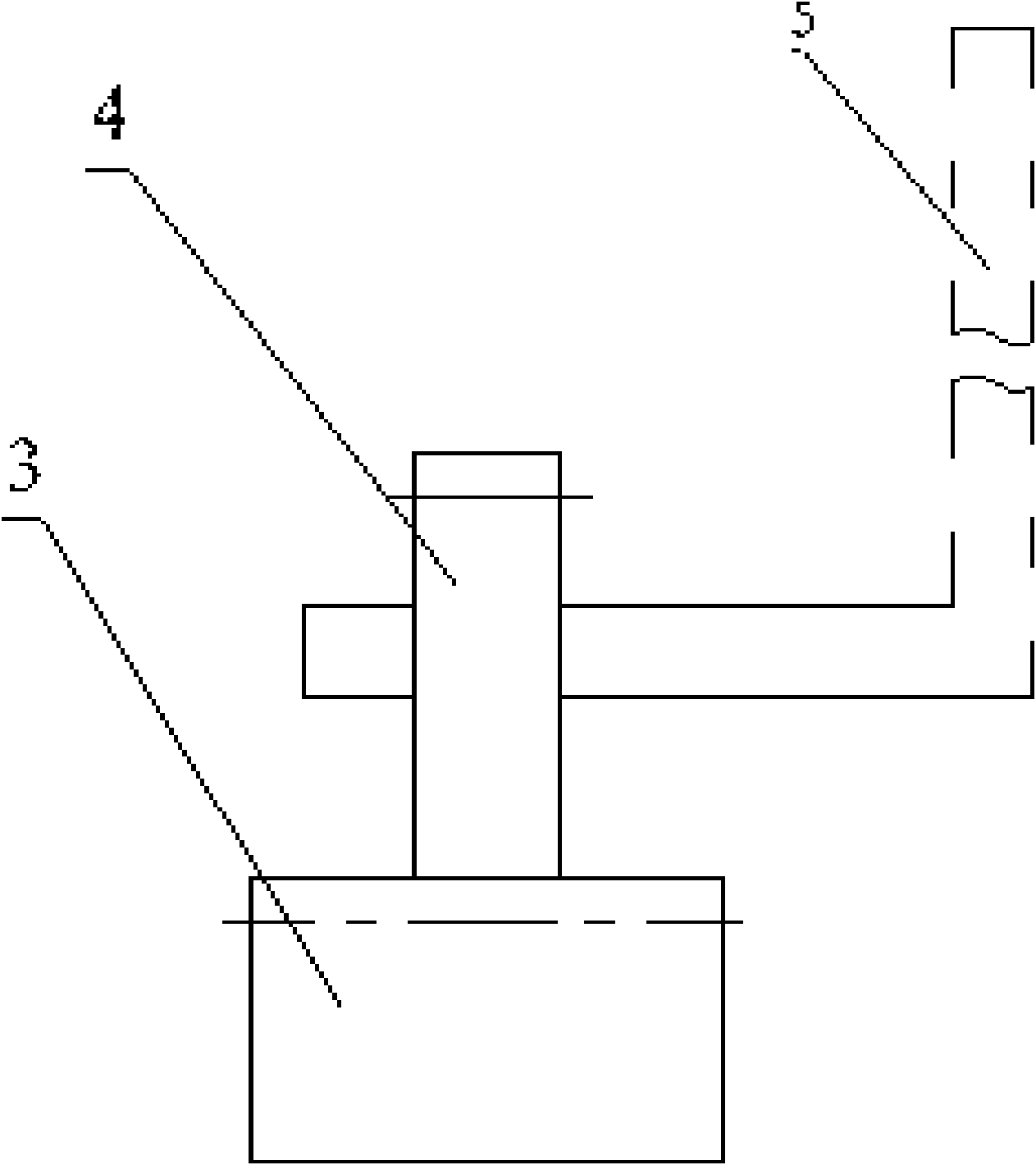

[0011] exist figure 1 Among them, a transmission device for an optical cable repeated bending test machine includes a crank slider mechanism, the crank slider mechanism includes a turntable 1, a connecting rod 2, and a toothed slider 3, and one end of the connecting rod 2 is hingedly arranged on the disk surface of the turntable 1 , the turntable 1 rotates around its center, the other end of the connecting rod 2 is hinged with one end of the toothed slider 3, and the toothed slider 3 is meshed with the gear 4 to form a rack and pinion transmission mechanism, and one side of the gear 4 is radially A fork 5 is fixedly arranged.

[0012] When moving, the motor (not shown in the figure) can be used to drive the turntable 1 to rotate in one direction around its center, and drive the connecting rod 2 to do plane movement, the connecting rod 2 is hinged with one end of the toothed slider 3, and the toothed slider 3 Driven by the rod 2, it makes a reciprocating linear motion, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com