Embedded vehicle-mounted cup fixing saucer assembly

An embedded, cup holder technology, applied in the field of auto parts, can solve the problems of lack of cup placement stability and safety, lack of cup clamping and fixing mechanism, falling objects or sundries, etc., and achieves good placement stability, The effect of not easy to pour and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

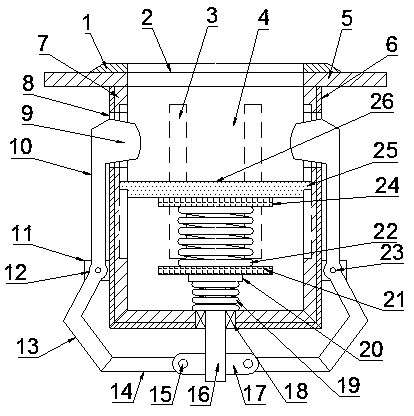

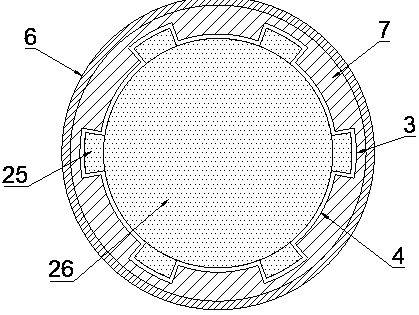

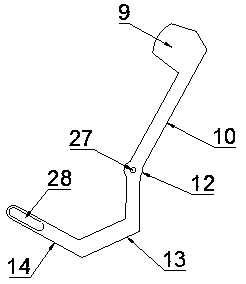

[0021] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0022] see Figure 1-3 , an embedded vehicle-mounted water cup fixing cup holder assembly, including a mounting panel 5, an outer cup holder 6, an inner cup holder 7, a push rod 16, a rotating shaft 23 and a water cup bearing cover 26, and an inner cup holder is fixed on the inner wall of the outer cup holder 6. The cup holder 7, the outer cup holder 6 and the inner cup holder 7 are all equipped with an open cylindrical structure at the upper end, and the top of the outer cup holder 6 and the inner cup holder 7 are welded with an installation panel 5, and the middle part of the installation panel 5 is provided with a cup inlet 2. The snap ring main body 1 is fixed on the mounting panel 5 on the upper edge of the cup inlet 2. The inner diameter of the snap ring main body 1 and the inner cup holder 7 are equal to the di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com