A kind of super-imitation cotton polyester nylon air-sprayed deformed mixed fiber yarn and its preparation method

A technology of super imitation cotton and mixed fiber yarn, which is applied in the direction of yarn, textile and paper making, and can solve the problems of short process flow, low cost and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

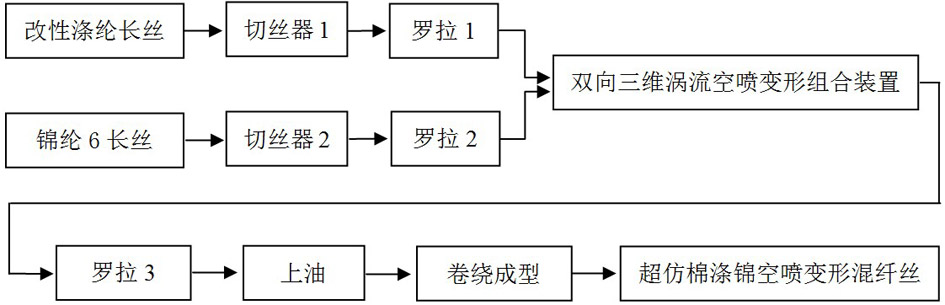

[0021] This embodiment provides a method for producing super-imitation cotton polyester nylon air-sprayed deformed mixed fiber yarn with a specification of 167dtex / 96f. For the process flow, see the attached figure 1 .

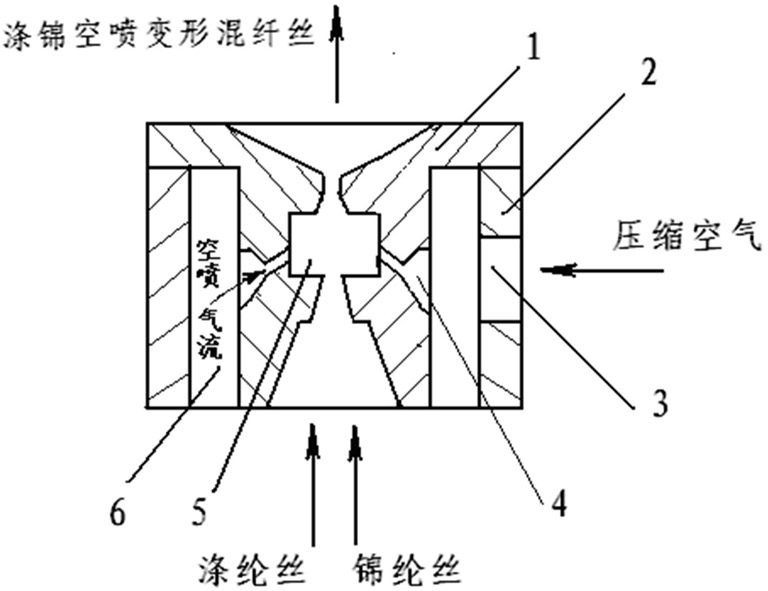

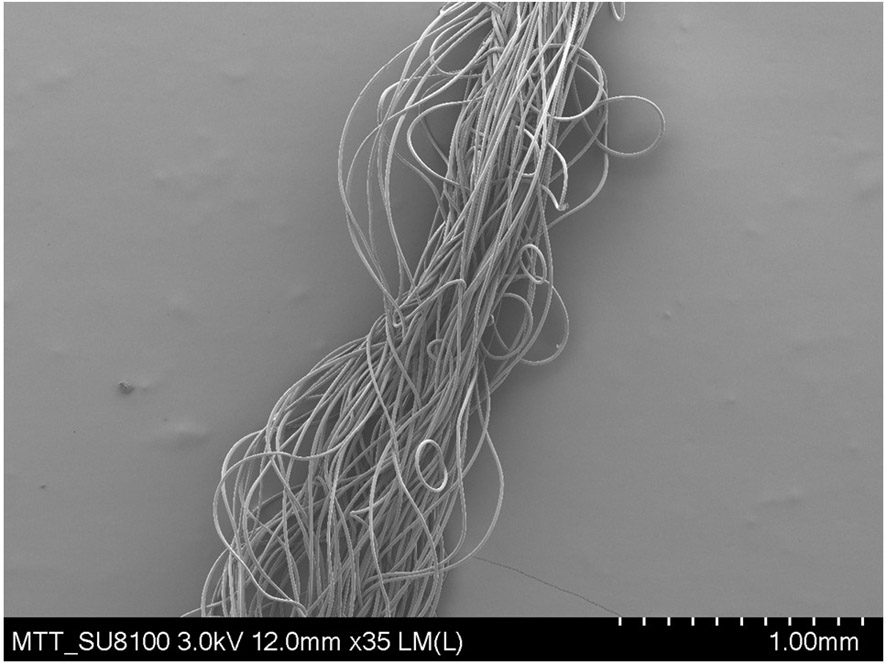

[0022] The production process conditions are as follows: On the same machine, the modified blended polyester filament and nylon 6 filament are fed into the two-way three-dimensional vortex air jet deformation combination device at the same time at different rates of overfeeding. The tow in the turbulence chamber of the air-jet nozzle is blown by the formed supersonic two-way three-dimensional vortex air-jet turbulent airflow, separated, and moves and turns violently in the two-way three-dimensional vortex air-jet turbulent flow, and then is separated from the vortex jet airflow Together, they continuously leak out from the turbulent flow area of the vortex, forming random intertwined mixed fibers, and making super-imitation cotton, polyester and nylon air-sp...

Embodiment 2

[0030] This embodiment provides a method for producing super-imitation cotton polyester nylon air-sprayed deformed mixed fiber yarn with a specification of 180dtex / 96f. For the process flow, see the attached figure 1 ; The two-way three-dimensional vortex air jet deformation combination device used is as follows: figure 2 shown. The production process conditions are as follows:

[0031]On the same machine, the modified blended polyester filaments and nylon 6 filaments are fed into the two-way three-dimensional vortex air jet deformation combination device at the same time at different speeds, and the two-way three-dimensional vortex air jets make the turbulent flow into the air spray nozzle The tow in the chamber is blown by the formed supersonic two-way three-dimensional vortex air-jet turbulent airflow, separated, and moves and turns violently in the two-way three-dimensional vortex air-jet turbulent flow, and then continuously flows from the vortex together with the vorte...

Embodiment 3

[0033] This embodiment provides a method for producing super-imitation cotton polyester nylon air-sprayed deformed mixed fiber yarn with a specification of 180dtex / 120f. For the process flow, see the attached figure 1 ; The two-way three-dimensional vortex air jet deformation combination device used is as follows: figure 2 shown. The production process conditions are as follows:

[0034] On the same machine, the modified blended polyester filaments and nylon 6 filaments are respectively fed into the three-dimensional vortex air-spraying deformation combination device provided by Example 1 at different speeds, and the two-way three-dimensional vortex air injection makes the entering The tow in the turbulence chamber of the air-jet nozzle is blown by the formed supersonic three-dimensional vortex air-jet turbulent airflow, separated, and moves and turns violently in the two-way three-dimensional vortex air-jet turbulent flow, and then together with the vortex jet airflow It c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

| shrinkage | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com